Restoring old motorcycles with resin 3D-printing.

Obtaining spare parts for equipment or vehicles that are still in production can be challenging. Try that with motorcycle parts that are out of production for more than two and a half decades. Bike from the brink is doing just that! They are restorting motorcycles to their former glory and saving them from the scrapyard. For some rare parts that are not available anymore, they are utilizing resin 3D-printing with Liqcreate resins just like they did for the Yamaha Virago 750 motorcycle that was produced between 1981 to 1998

Their youtube channel shows a video diary of restoring motorcycles to their former glory. The goal is to share the restorations and maybe the findings, triumphs but also failures that might help someone with their own bikes. In this article we present the story from Ben from Bike from the Brink which illustrates how they manufacture Yamaha Virago carburetor (carbs) manifolds that are no longer in commercial production with the help of Liqcreate resins. Motorbikes that are over 30 years old have carbs that often need a full overhaul and most of them are beyond repair.

After designing and testing the part on the motorcycle, it became apparent that hobby grade materials were inadequate... Liqcreate Strong-X was the best for the job.

Ben from Bike from the brink

Ben says: “After designing parts and testing the design on the motorcycle, it became apparent that hobby grade materials were inadequate when it came to this task (carburetor manifold). On my first FDM prototype the bike backfired and blew the print apart. I started to research robust materials and quickly realized I needed a resin printer. Quickly after it was ordered along with some Liqcreate samples to test. I used the Liqcreate TDS (technical data sheet) to determine which materials might be suitable for the task ahead. It is a big ask for a piece of plastic to be strong, impact proof, petrol proof, waterproof and heat resistant. My own testing determined that Liqcreate Strong-X was the best for the job. After several prototypes were sent to members of the public, feedback was received, and we came to a final design for the Virago 535 manifold.“

Manufacturing spare parts for restoring old motorbikes with resin 3D-printing.

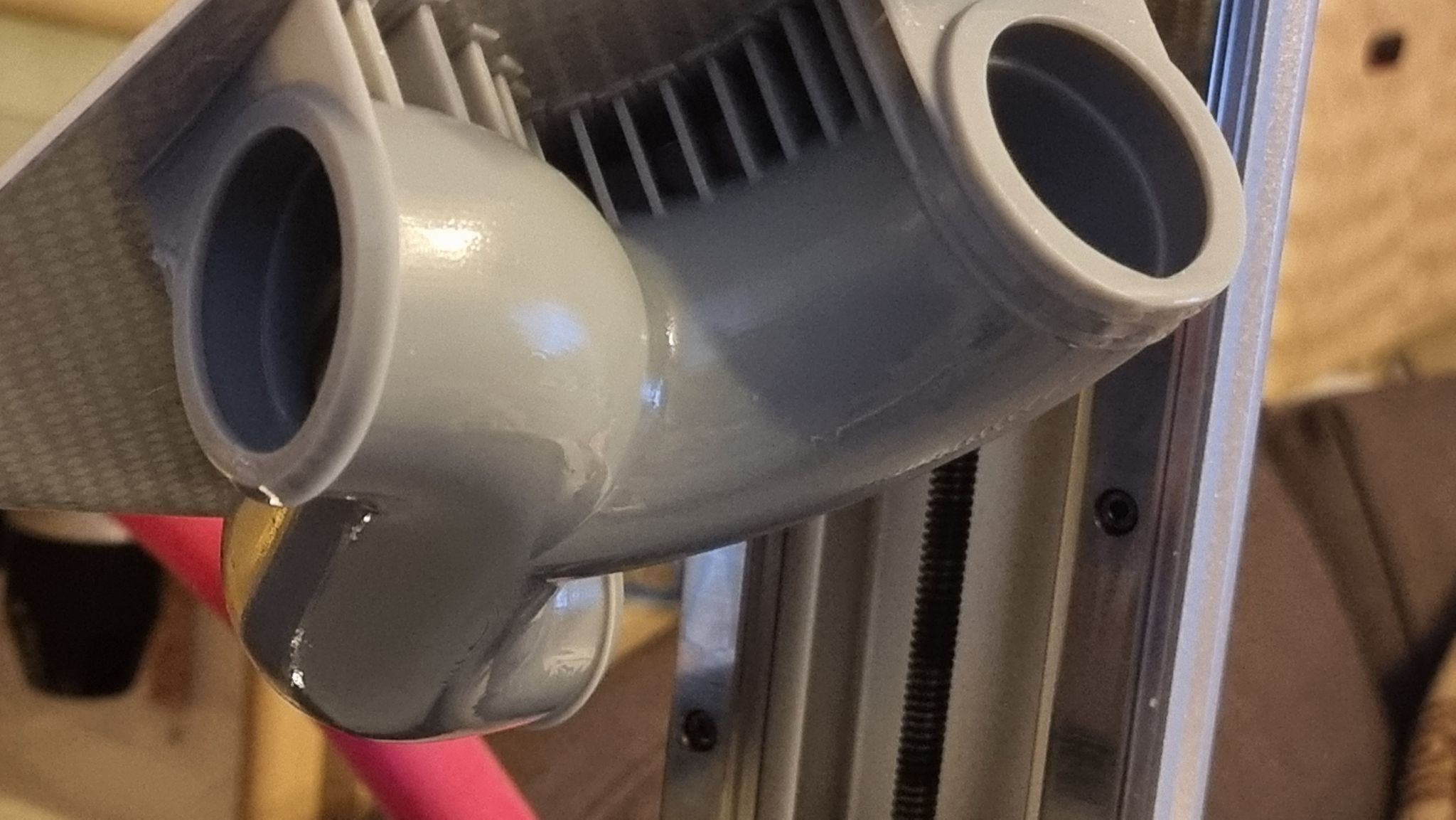

Liqcreate Strong-X was chosen as preferred resin due to its high strength, good temperature resistance and oil and fuel compatibility. For the carburetor manifold, the fuel flows through it, but this should not be at high temperature. If the bike isn’t set up right and the engine backfires the heat is only brief. Other resins could not withstand the pressure of the explosion during a backfire, but Strong-X endures. The manifolds were designed to sit in the original rubbers which act as a heat break and shock absorber. After designing a manifold and testing the 3D-printed part for fit and function, it will be taken into production. Finally, the production parts were 3D-printed with Liqcreate Strong-X resin, washed and UV-cured, before final assembly. UV-curing gives Strong-X parts its final mechanical, thermal and chemical resistant properties.

Image: Finalized design for the Virago 535 carburetor manifold.

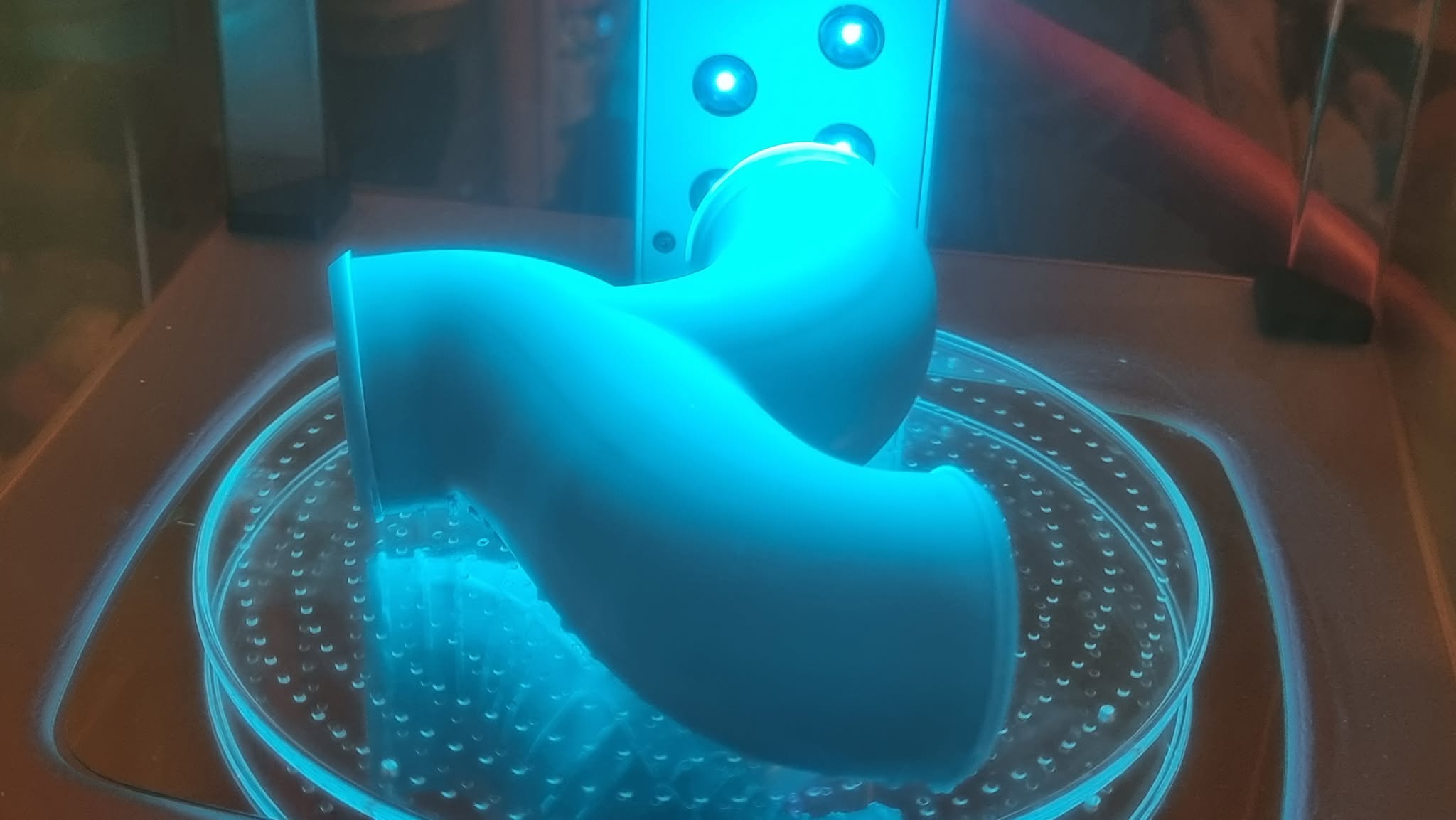

Image: 3D-printing the final design in Liqcreate Strong-X will take approximately 100 gram of resin.

Image: After 3D-printing and washing, the 3D-printed part made from Strong-X need UV-curing to reach its final properties.

Image: Final part made with Liqcreate Strong-X resin ready for assembly.

Image: Assembly of the 3D-printed Strong-X part on the Yamaha Virago 535 motorbike.

Offering spare parts with Liqcreate Strong-X for the complete line of Virago 400-1100 sized engines.

Additionally, Bike from the brink also made a carb manifold to fit the Yamaha Virago 750, completing their portfolio for all Virago 400-1100 sized engines. The manifolds are designed to be used with any carb, including the popular pwk34 clone. When they were still in production, a set of new carbs for this motorbike would cost about £1200. And set of fully serviced (used) ones were approximately £400. With the use of the manifolds from Bike from the brink, motorbike enthousiasts are now again capable to restore their old bikes without breaking the bank.

Image: Assembly of the 3D-printed Strong-X part on the Yamaha Virago 750 motorbike.

When Ben started they had failures within seconds with FDM 3D-printed parts. The carburetor manifolds manufactured with Liqcreate Strong-X have been out there for more then 12 months. There are many out there, all around the world and none of the Strong-X parts have been reported to fail.

Ben continues: “Next up is an even more challenging project. Someone said the expansion tank for a 1989 ZXR750 H1 was not available anywhere. The tank was difficult to model in CAD and the first try was fit for purpose but a little unsightly. After obtaining a 3D scanner it was possible to get the right shapes. It was at this time that Liqcreate released the new Flame Retardant HDT resin, just as I was looking for something which might cope with expansion tank temperatures. As of right now I’m prototyping the expansion tank with the HDT resin, nothing like the material’s original intended purpose, but I have a feeling it will be up to the job as initial testing is going well.”

Liqcreate Strong-X

Liqcreate Strong-X is one of the strongest materials available in the market. Its flexural strength of 135MPa is comparable to industry’s leading dual-cure cyanate ester resins. Liqcreate Strong-X is easy to use on all open source SLA and DLP 3D-printers in the range of 385 – 405nm and only requires UV post-curing. This material has excellent features like high strength, high stiffness and high temperature resistance which makes it ideal for injection molding and heavy duty applications.

Key benefit

· High strength · High temperature resistance · Low odor · Low shrinkage |

3D-Printer compatibility

· Asiga & Creality series · Formlabs Form2 · Anycubic & Elegoo series |