Forma: Applications of 3D-printing in the hand surgery sector

FORMA is a design and 3D printing studio established in 2020 in Padua, Italy. The beating heart of the studio is the laboratory, a place where creativity and experimentation take place. Here they like to test every possible application of 3D printing. Equipment at Forma includes both resin 3D-printers and filament 3D-printers. The main focus of Forma is on product design and mechanical applications, but a consistent part of their job involves 3D printing for orthopedic purposes, in particular for the hand surgery sector. Together with orthopedic surgeons, Forma creates innovative solutions for the treatment of patients.

In this article, experts at Forma explain how they are utilizing 3D-printing with Liqcreate Dental Model Pro Grey and Premium White resin to improve health-care. By making accurate bone models from CT-data and design custom-made 3D-printed braces.

One of the activities of Forma concerns the creation of anatomical models starting from CT scan or MRI. Forma provides the orthopedic surgeons a very useful tool that can help in the pre-operative phase, in order to identify the best strategy. Using 3D printed model, the orthopedic surgeons can understand in an easier way the problem of the patient. Furthermore the orthopedic surgeons can simulate the surgery and shape plates and screws before even entering the operating theatre. As a result, the success rate of the surgery increases, while risks for the patient decrease. Additionally less time is required to practice the surgery (less bleeding, less anesthetic needed).

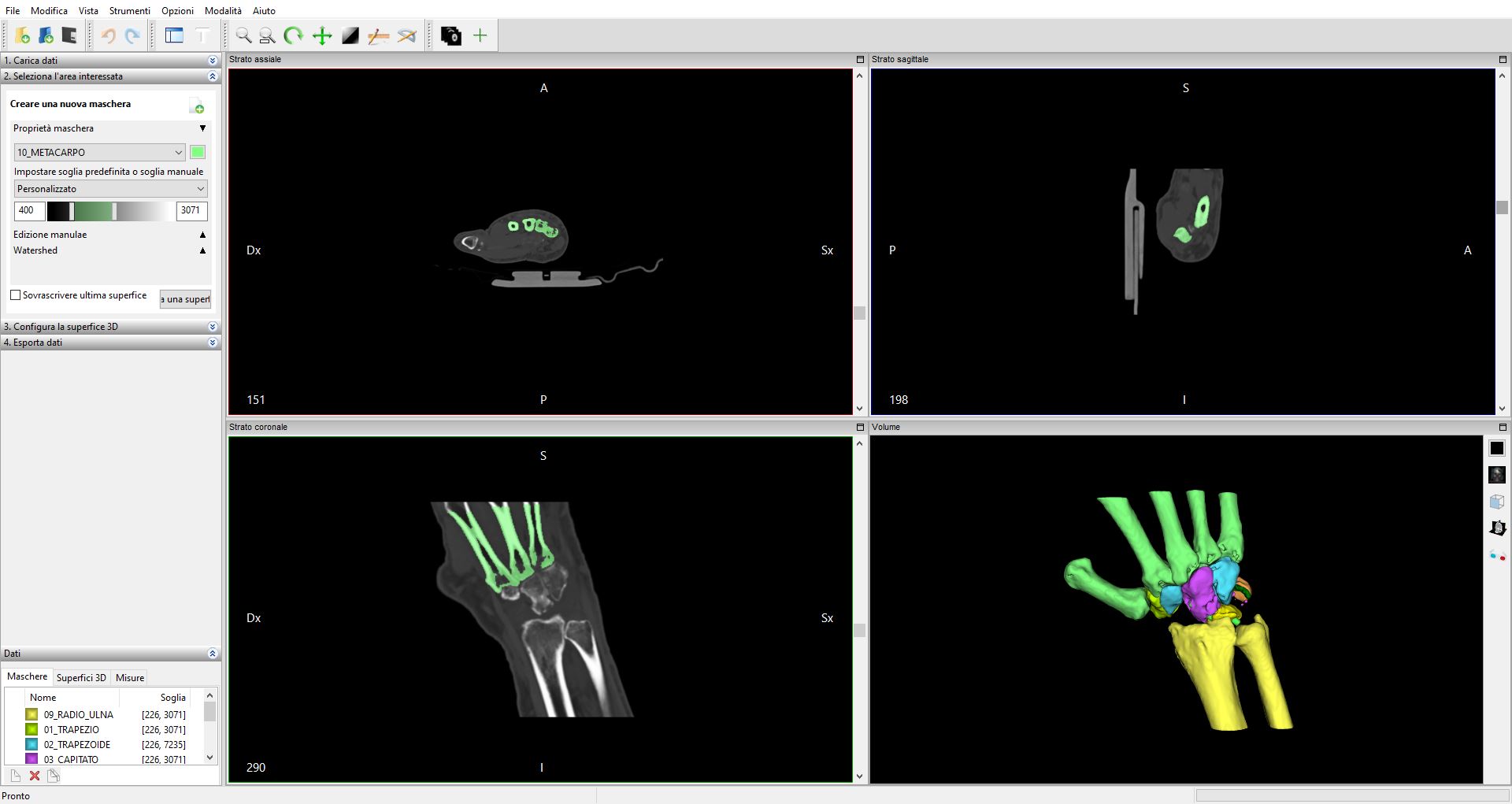

Image by Forma: CT-data after CT-scan to prepare the model for 3D-printing resin parts in the hand surgery sector

The process explained

The entire process can be divided in two steps: At first, the three-dimensional model has to be extracted starting from the diagnostic test. During this procedure, Forma is in constant touch with the orthopedic surgeons, in order to achieve the best result. It this phase it is important to identify the issue to be solved and correctly isolate the anatomical region of interest. The accuracy of the diagnostic test plays also an important role. The CT scan, for example, must have an high level of detail; for this reason a thin-layer CT scan is the best choice, with a distance between the section planes of less than 3 mm. The 3D model is obtained by software that allows to highlight, for each frame of the CT scan or MRI, the significant elements. Each pixel selected in the two-dimensional image corresponds to a voxel in the three-dimensional space, with a layer height equal to the single layer height of the CT scan. The selection can be done automatically or manually, depending on the complexity of the case or the quality of the images. In this case, it must be underlined that the presence of plates and screws, which are often used in orthopedic practice, cause over-exposure of the image obtained by CT, with a consequent loss of detail. In these cases the three-dimensional reconstruction process is more expensive because it requires a lot of manual work. Once the selection work is finished, thee final 3D model is obtained.

Image by Forma: CT-data converted in STL file, ready for resin 3D-printing.

Image by Forma: Aftrer the CT-scan data is converted in to a printable format (STL) the bone structures can be printed, in this example is 3D-printed with Liqcreate Premium White resin. Resin 3D-printing provides detail and accuracy needed for the hand surgery sector.

The second step is 3D printing the digital model. According to the typology of the model, Forma choose the most suitable printing technique between FDM and DLP/SLA. When it comes to complex anatomical parts, very detailed, where high levels of definition are required, resin 3D-printing is the best choice. The following case shows the clinical outcomes of a scaphoidectomy in a patient with a SNAC advanced collapse syndrome. Since the first surgery was not successful, it was necessary to practice a new surgical procedure. The orthopedist asked Forma to provide an anatomical model of the carpal region for planning purposes. In this case Forma used Liqcreate Dental Model Pro Grey resin, an high quality product that allows you to highlight every single detail. Therefore, thanks to its stability and low shrinkage, this resin significantly increases the success rate of each individual print.

Image by Forma: 3D-printed part made from an CT-scan data, 3D-printing with Liqcreate Dental Model Pro Grey resin.

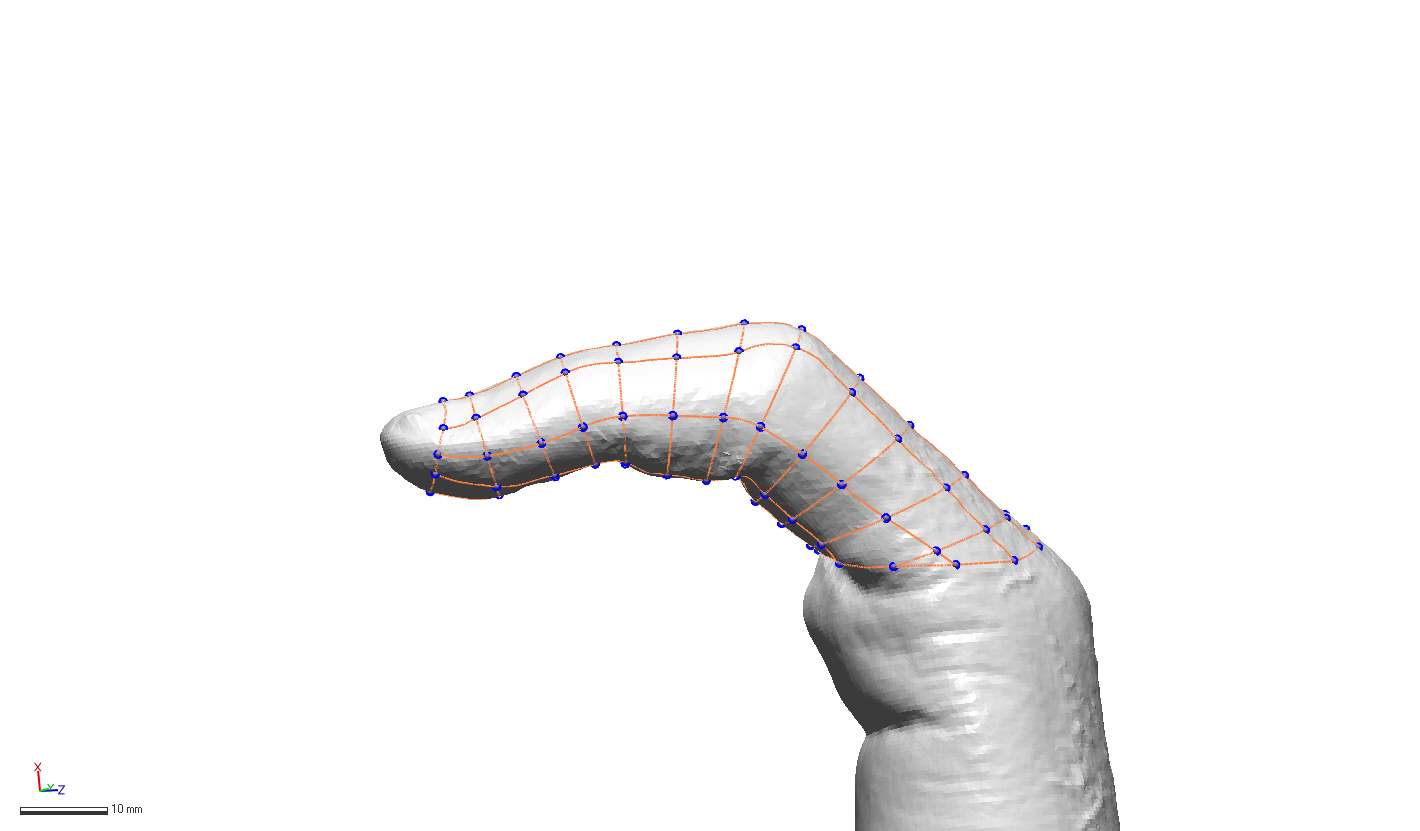

Another innovative application of 3D printing in orthopedics is the creation of custom-made braces. In the following case Forma designed and printed an orthosis for the treatment of a fracture of the middle phalanx of the little finger. After detecting the area with a 3D scanner, the brace was designed using the scan as a reference. Finally, the model was printed with Liqcreate Premium White resin. This kind of brace offers several advantages, as it ensures the articular immobilization. At the same time it is comfortable to wear. Furthermore, it’s water resistant and thanks to its strength it protects the finger from accidental bumps.

Image by Forma: design of custom-made braces for the hand surgery sector and 3D-printing with Liqcreate Premium White resin.

These are just a few examples of how 3D printing is changing the medical industry, and Forma’s commitment is to continue developing innovative solutions for the treatment and care of patients. Learn more about this project and other project by Forma on their website www.3dforma.it, instagram or send us an e-mail at info@liqcreate.com.