For some applications, it is needed to have waterproof or airtight enclosures. Originally a lot of these parts were designed and printed with FDM technology. With the fusing of layers and sometimes porosity it is quite difficult to get a good waterproof or airtight enclosure made from filament. there are many instructions and tips & tricks how to get better results. With resins this is much easier. Properly printed SLA / MSLA or DLP 3D-printed are waterproof and airtight and most cured resins have extremely low water absorption. If you are looking to make a waterproof or airtight enclosure, resin 3D-printing would be the best technique.

Resin selection for waterproof & airtight enclosures

it first starts with selecting the right resin. This is depending on the properties you need and also the equipment you have. Liqcreate resins are working on over 90 different 3D-printers, here you can find the list of compatible printers. For waterproof containers you would want to stay away from water washable resins and resins with >1% water absorption. Typically water washable resins have a very high water absorption and would not function for long in an environment with high amount of moisture or water. Most Liqcreate resins can work fine. select the material with the lowest water absorption from this list. Some companies are using Liqcreate resins for airtight connectors which work great. Next to selecting the resin with the right properties, the print orientation and post-processing play a major role in a succesful waterproof or airtight 3D-printed part.

3D-printing a waterproof & airtight part.

As said, next to selecting the right resin, print orientation and design plays a major role in producing a waterproof or airtight part. There are a few guidelines to follow to get the best succes rate.

1) Never print a hollow part without ‘drain holes’

If you want to print an airtight or waterproof part that is completely closed and hollow from the inside, it is almost impossible to print without defects. All hollow parts would need a drain hole, preferably at the lowest point of the model close the the build plate. This will eliminate pressure build-up in the model and give a very bad surface finish. If the pressure is too high inside the part, also the walls can break and your part won’t be watertight / airtight. If your part needs to be completely closed without any holes, then you can fill the holes with resin after washing. Put some resin in the holes and cure it to have a completely closed container.

2) Select the right orientation for your part

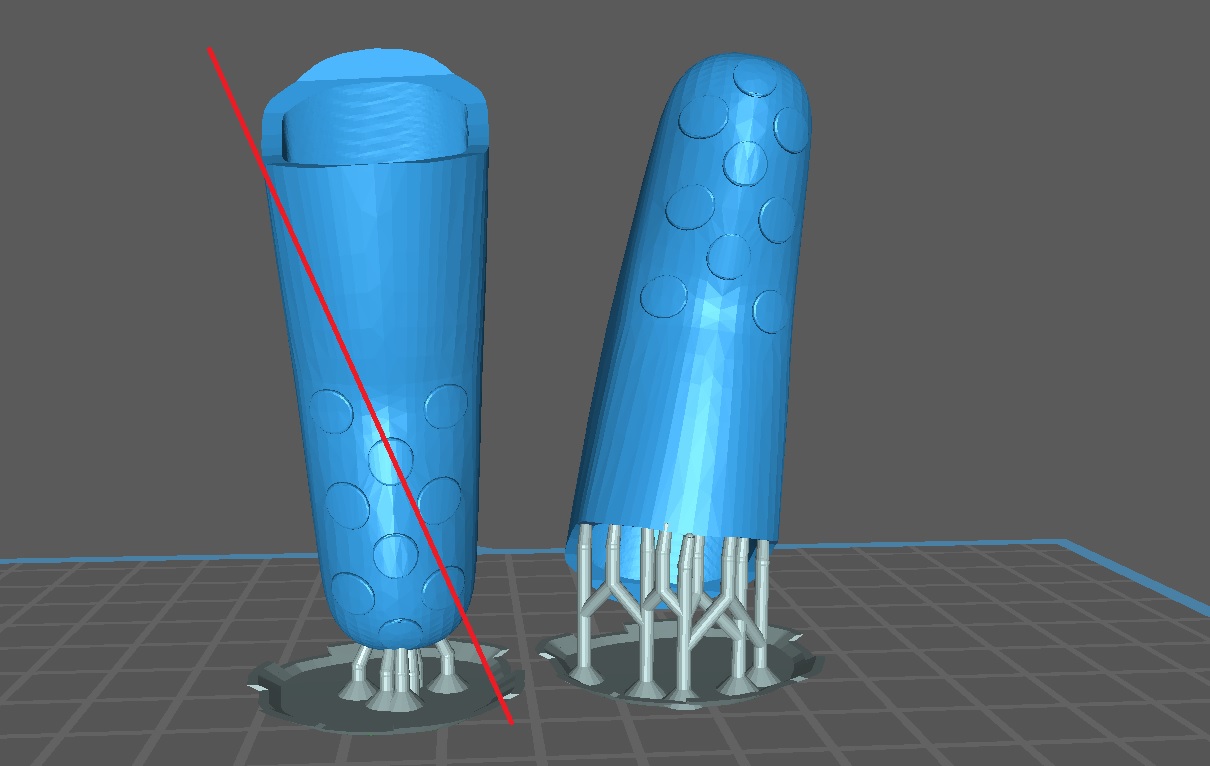

For some parts this is very crucial. if you are printing a shape like a hollow tube with one opening, as in the picture below. Then the wrong orientation can cause the same issues as discussed in point 1. you want to prevent any hollow parts to build up pressure. As this type of file is open from one part, it can be easily fixed by the right orientation as shown in the image below. Turn the part so the opening is on the bottom and tilt the part 10 degrees to the left or right.

3) Wash and post-cure properly

When washing a part, make sure you can wash the outside and in case of a hollow part, also the inside properly. Instructions on washing can be found in this article. Post-curing instructions are published here. Make sure to wash the parts properly and only cure when the parts are not sticky anymore an all leftover resin is washed off. often leftover resin can be seen when the parts are still shiny. Proper post-curing is needed to get to the parts final properties, including its water absorption properties.

4) Test and inspect the waterproof or airtight parts properly before using

it is always advised to test and inspect the part before using it. make sure that there are no print failures resulting in holes or that all prepared drain holes are closed properly with resin. Additionally, make sure that all seals are printed straigth and there is no water or air leakage before use.

We hoped this was an interesting and educational read. Please send us an e-mail at info@liqcreate.com if you have any questions, comments or remarks. We wish you happy printing and have fun with your colored resin!

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!