Researchers and students at the University of Applied Science investigated the UV aging and UV stability of 3D-printed Liqcreate resins. The aim of this research was determining the effect of UV light on Liqcreate resins in the long-term. The analysed resins in this research were the Tough-X, Flexible-X, Strong-X, Composite-X, Elastomer-X and Rigid Pro resins. The resins were aged in a climate chamber were 3D-printed samples were exposed to UV light. During this research, polymers that were not exposed to UV light were selected as a reference (Coded: 0 hours). The other specimen were exposed for respectively 168 and 336 hours to silumate UV aging. The second round of testing was performed at 336, 672 and 1008 hours of UV-aging. Several mechanical tests were performed to analyse the effect of UV aging and UV stability on the 3D-printed resin, including IZOD Impact, Tensile strength, elongation at break and Hardness. Learn more about the different mechanical tests here.

UV aging setup

UV aging was performed in an Ametek, Atlas Fluorescent UV /Condensation Weathering Instrument. The specimen were exposed for respectively 0, 168 and 336 hours with an UV Irradiance of 0,89 W/m2 at 25°C. 336 Hours of exposure is roughly 4,5 years real-time indoor aging, while 1008 hours of exposure is roughly 13,5 years real-time indoor aging.

Sample preparation for UV stability and UV aging

All resins were 3D-printed on a 405nm DLP 3D-printer with pre-programmed Liqcreate resin settings. The samples were placed in the long direction on the platform, which is often seen as the weakest position to print. After 3D-printing, samples were washed in IPA for 2 times 3 minutes, dried and post-cured according to advised settings in the Wicked Engineering Curebox. For the mechanical tests, the following specimen and tests were selected:

- – ASTM D638 Type 4 dogbone for tensile strength, modulus and elongation measurements

- – ASTM D256A specimen for Notched IZOD Impact strength

- – ASTM D2240 specimen for Shore D hardness

UV aging and UV stability of Liqcreate Tough-X resin

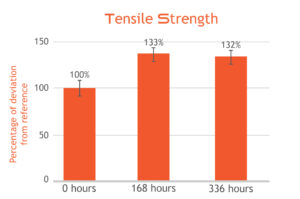

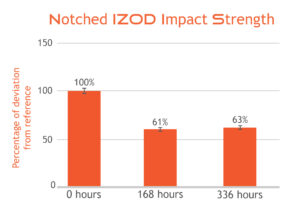

Results for the UV aging and UV stability of Liqcreate Tough-X resin:

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Technical →

Tough-X becomes slightly more rigid with an 11% increase in modulus 8% reduction in elongation after 336 hours exposure. The extremely high impact of Tough-X reduces to 63% while the strength increased with 32% compared to a sample that is not aged. When designing a part for long-term use, these deviations should be taken into account.

Liqcreate Tough-X

Liqcreate Tough-X is an opaque black photopolymer resin. 3D-printed parts from this resin have exceptional durability. Liqcreate Tough-X is easy to use on all open source DLP, LCD and SLA 3D-printers in the range of 385 – 420nm. This material has excellent properties like high impact strength and up to 150% elongation, making it perfect for the production of industrial spare parts and functional tough and hard-rubber replacement products.

Key benefits |

3D-Printer compatibility |

| · Exceptional Impact Strength | · Epax3D Series |

| · High Elongation | · Phrozen3D Series |

| · Rigid rubber properties | · Elegoo & Anycubic Series |

| · Heavy Duty | · And many more |

UV aging and UV stability of Liqcreate Flexible-X resin

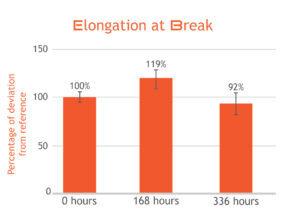

Results for the UV aging and UV stability of Liqcreate Flexible-X resin:

Both the elongation at break as the tensile strength show a slight reduction to compared to its original properties after 336 hours of UV-aging of Flexible-X. While this resin slightly becomes more rigid after aging. An increase of 30% meaning that its original Shore A hardness of 55 will increase to 71 after extended UV-exposure.

Liqcreate Flexible-X

Liqcreate Flexible-X is an opaque black photopolymer resin with great processability and print speed on MSLA, DLP and laser based 3D-printers. 3D-printed parts from this resin have exceptional flexibility and great rebound properties. Liqcreate Flexible-X is easy to use on all open source DLP, LCD and SLA 3D-printers in the range of 385 – 420nm. Its low hardness of 55 Shore A and elongation up to 160% makes it perfect for the production of a diversity of industrial applications.

Key benefits |

3D-Printer compatibility |

| · High Elongation | · Epax3D Series |

| · Excellent Rebound | · Phrozen Series |

| · Good Tear Strength | · Anycubic series |

| · Durable Soft Touch | · And many more |

UV aging and UV stability of Liqcreate Strong-X resin

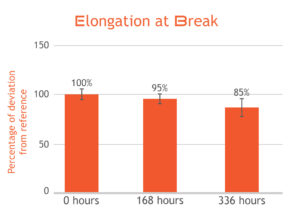

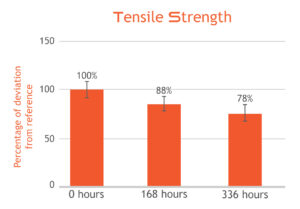

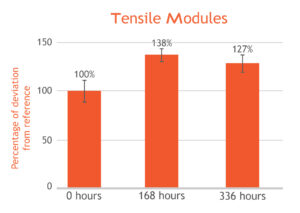

Results for the UV aging and UV stability test of Liqcreate Strong-X resin:

Strong-X is an extremely strong and rigid 3D-printing resin. After aging, the properties slightly change and the material tends to be more rigid. The original elongation of 5-8% drops to 3-7% after 336 hours of UV-exposure, while the Shore D hardness does not change. A slight drop in tensile strength is found compared to an increase in modulus.

Liqcreate Strong-X

Liqcreate Strong-X is one of the strongest resins available in the market. Its flexural strength of 135MPa is comparable to industry’s leading dual-cure cyanate ester resins. Liqcreate Strong-X resin is easy to use on all open source SLA and DLP 3D-printers in the range of 385 – 405nm and only requires UV post-curing. This material has excellent features like high strength, high stiffness and high temperature resistance which makes it ideal for injection molding and heavy duty applications.

Key benefits |

3D-Printer compatibility |

| · High strength | · Epax3D Series |

| · High temperature resistance | · Formlabs Form2 |

| · Low odor | · Asiga & Anycubic series |

| · Low shrinkage | · And many more |

UV aging and UV stability of Liqcreate Composite-X resin

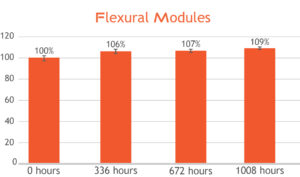

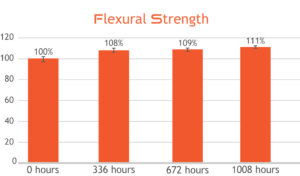

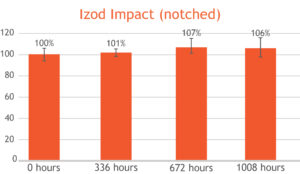

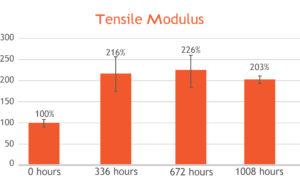

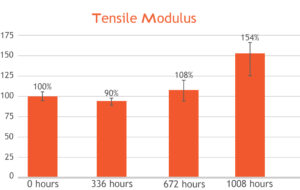

Composite-X is an extremely strong and rigid 3D-printing resin. After aging, the properties slightly change and the material tends to be more rigid, although the differences are rather small. In the worst tested case, Izod Impact strength was down 8% after 1008 hours aging while strength reduced by 9% and modulus increased by 9%. This indicated very good UV-stability for Liqcreate Composite-X resin.

Results for the UV aging and UV stability test of Liqcreate Composite-X resin:

Composite-X

Liqcreate Composite-X is an extremely rigid and high performance reinforced nano-micro composite resin for SLA, DLP & LCD / MSLA in the range of 385 – 420nm. Perfect for rapid tooling, wind tunnel testing, medical modeling and industrial applications.

Liqcreate Composite-X is one of the stiffest and strongest material available in the market. It has a flexural modulus over 9000 MPa and a flexural strength of 150 – 170 MPa. The material can be used after UV-post curing, or the properties can be boosted with a thermal cure. This material has features like excellent chemical resistance, high strength and high stiffness.

Key benefits |

3D-Printer compatibility |

| · High rigidity | · Phrozen3D Series |

| · High strength | · Atum3D DLP Station 5 |

| · Low odor | · Elegoo & Anycubic series |

| · Good chemical resistance | · And many more |

| · Extremely low shrinkage |

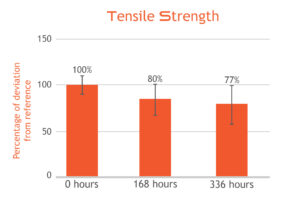

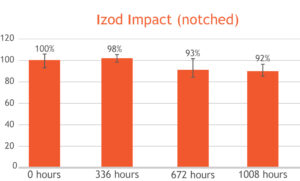

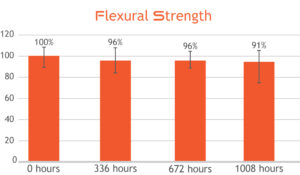

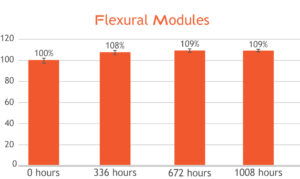

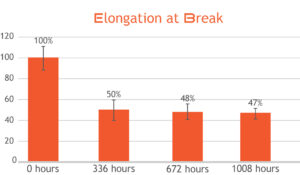

UV aging and UV stability of Liqcreate Rigid Pro resin

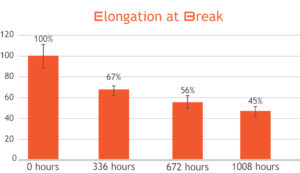

Rigid Pro is an well ballanced rigid strong and rigid 3D-printing resin. After aging, the properties do change more rigid material. The elongation at break halves while the notched IZOD Impact strength slightly increases.

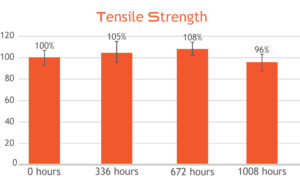

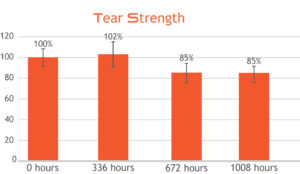

Results for the UV aging and UV stability test of Liqcreate Rigid Pro resin:

Liqcreate Rigid Pro

Liqcreate Rigid Pro is a rigid black photopolymer resin and can be processed on most open DLP, MSLA and laser based 3D-printers operating at a wavelength of 385-405nm. 3D-printed parts from this material exhibit high strength and rigidity. Liqcreate Rigid Pro only requires UV post-curing with heat to reach its optimal strength. This material has excellent features like: high stiffness, durability, high strength and good temperature resistance which makes it ideal for molding, and industrial applications like pulleys, automotive connectors, covers, brackets, housings and demanding engineering parts.

Key benefits |

3D-Printer compatibility |

| · High strength | · Asiga & Nexa3D series |

| · Dimensional stability | · Elegoo & Anycubic series |

| · Good chemical stability | · Phrozen & Creality series |

| · Good temperature resistance | · And many more |

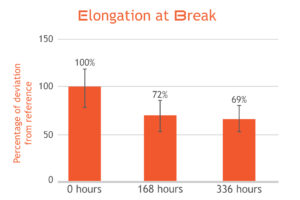

UV aging and UV stability of Liqcreate Elastomer-X resin

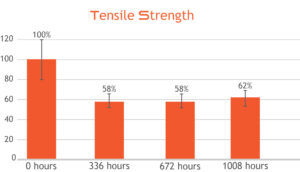

Elastomer-X is a super soft and flexible 3D-printing resin. The material changes after UV-aging in a more rigid material. While its tear strength is still decent, the elongation at break halves as well as the tensile strength. For some demanding applications UV-aging of Elastomer-X can be critical.

Results for the UV aging and UV stability test of Liqcreate Elastomer-X resin:

Elastomer-X

Liqcreate Elastomer-X is a clear photopolymer resin and can be processed on MSLA (LCD), DLP and laser based 3D-printers. 3D-printed parts from this material are exceptionally soft with a Shore A of 43 and have great flexibility. The product can be used as received, or colored with almost any commercial available 3D-resin colorants. Liqcreate Elastomer-X is can be used on open DLP, LCD and SLA 3D-printers in the range of 385 – 420nm. Its properties simulate soft TPU and silicone which makes it perfect for the production digital lattice foams, soft end of arm tooling (EOAT) for robots, grommets, bellows and elastic industrial parts.

Key benefits |

3D-Printer compatibility |

| · High Elongation | · Shining3D Accufab-L4K |

| · Mimics silicone and soft TPU | · Phrozen & Anycubic series |

| · Low Shore A hardness | · Elegoo & Creality series |

| · Ideal for soft digital lattice foams | · And many more |