With the adoption of Liqcreate resins in the consumer goods, automotive and aerospace sector, more data on UV-aging, chemical compatibility and thermal aging is requested. Previously UV-aging and chemical compatibility was tested. The results of UV-aging of Liqcreate 3D-printing resins can be found here. Chemical resistance and chemical compatibility of Liqcreate 3D-printing resins is published in this article. In this article the focus is on thermal aging of our resins.

Thermal aging of 3D-printing resins

Accelerated thermal aging is often used to determine the life-time of a plastic. The Arrhenius equation is used to determine the accelerated aging time. The aging was performed in a laboratory stove and test samples were exposed for 28 days at 80°C / 176 °F. Using the Arrhenius equation, this is similar to 5 years aging at room temperature.

Sample preparation for thermal aging

The samples were printed on a 405nm DLP 3D-printer and oriented in Z-axis. The Z-axis is often described as the most critical axis and will give a good view how the material performed in worse-case conditions. 3D-printed samples were tested according to the corresponding standards, more information on the test method and what the mechanical properties mean can be found here. Standard washing and post-curing protocols were followed.

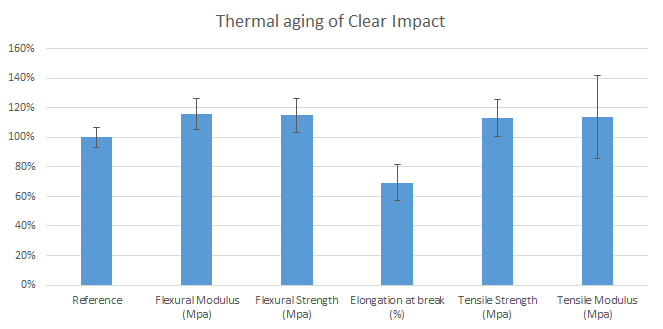

Properties of Clear Impact after thermal aging.

The mechanical properties of Clear Impact were measured after 28 days of thermal aging at 80°C / 176°C. The reference was scaled at 100% and deviation compared to the reference are published below.

After themal aging, the properties of Clear Impact slightly changed to a more rigid material. Elongation reduced with 31% while stiffness and strength increased with respectively 16% and 15%.

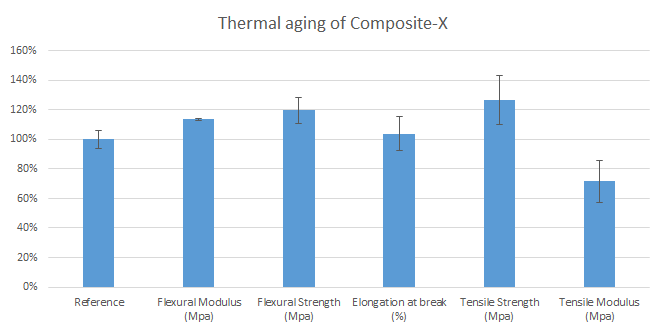

Properties of Composite-X after thermal aging

The mechanical properties of Composite-X were measured after 28 days of thermal aging at 80°C / 176°C. The reference was scaled at 100% and deviation compared to the reference are published below.

Most properties of Composite-X increased slightly after thermal aging. Thermal post-cure is also advised for Composite-X to boost its properties. Increase up to 26% was noticed for its tensile strength, while only the tensile modulus decreased.

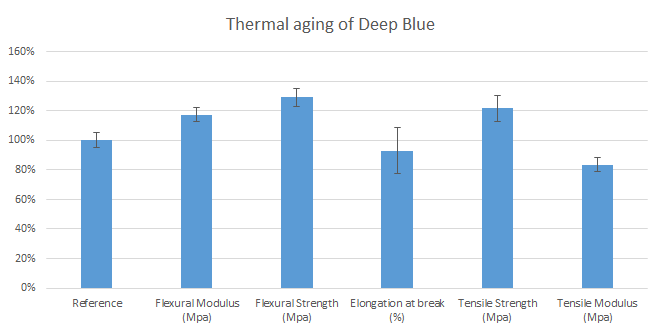

Properties of Deep Blue after thermal aging

The mechanical properties of Deep Blue were measured after 28 days of thermal aging at 80°C / 176°C. The reference was scaled at 100% and deviation compared to the reference are published below.

Similar to Clear Impact, the properties of Deep Blue slightly changed after thermal aging. The material became more rigid and an increased strength was found. With only a slight drop in elongation and tensile modulus of respectively 7 and 17%.

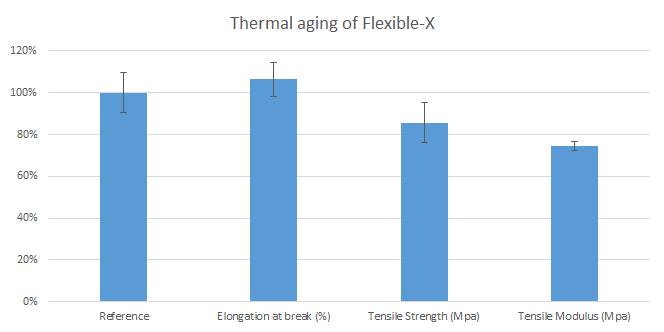

Properties of Flexible-X after thermal aging

The mechanical properties of Flexible-X were measured after 28 days of thermal aging at 80°C / 176°C. The reference was scaled at 100% and deviation compared to the reference are published below.

Flexible-X is a soft rubber-like 3D-print resin. After 28 exposure to 80°C / 176°C, the material properties slightly changed. The elongation increased with 6% while the tensile strength and tensile modulus decreased with respectively 14 and 26% from its original properties.

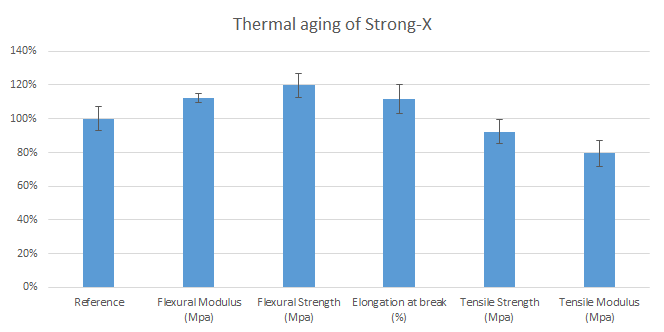

Properties of Strong-X after thermal aging

The mechanical properties of Strong-X were measured after 28 days of thermal aging at 80°C / 176°C. The reference was scaled at 100% and deviation compared to the reference are published below.

Most properties of Strong-X increased slightly after thermal aging. Increase up to 20% was noticed for its flexural strength, while only the tensile modulus and tensile strength decreased.

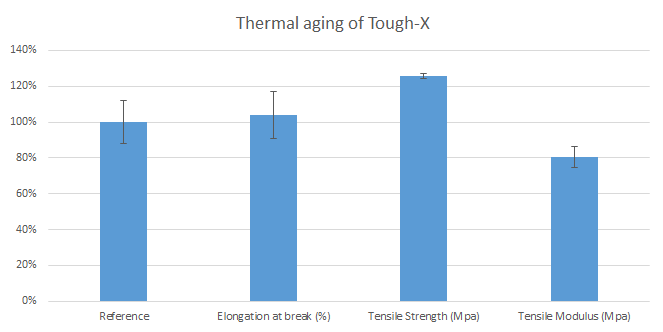

Properties of Tough-X after thermal aging

The mechanical properties of Tough-X were measured after 28 days of thermal aging at 80°C / 176°C. The reference was scaled at 100% and deviation compared to the reference are published below.

The mechanical properties of Tough-X is are quite stable after 28 exposure to 80°C / 176°C. The tensile strength increased with 26% while the tensile modulus decreased with 19%.

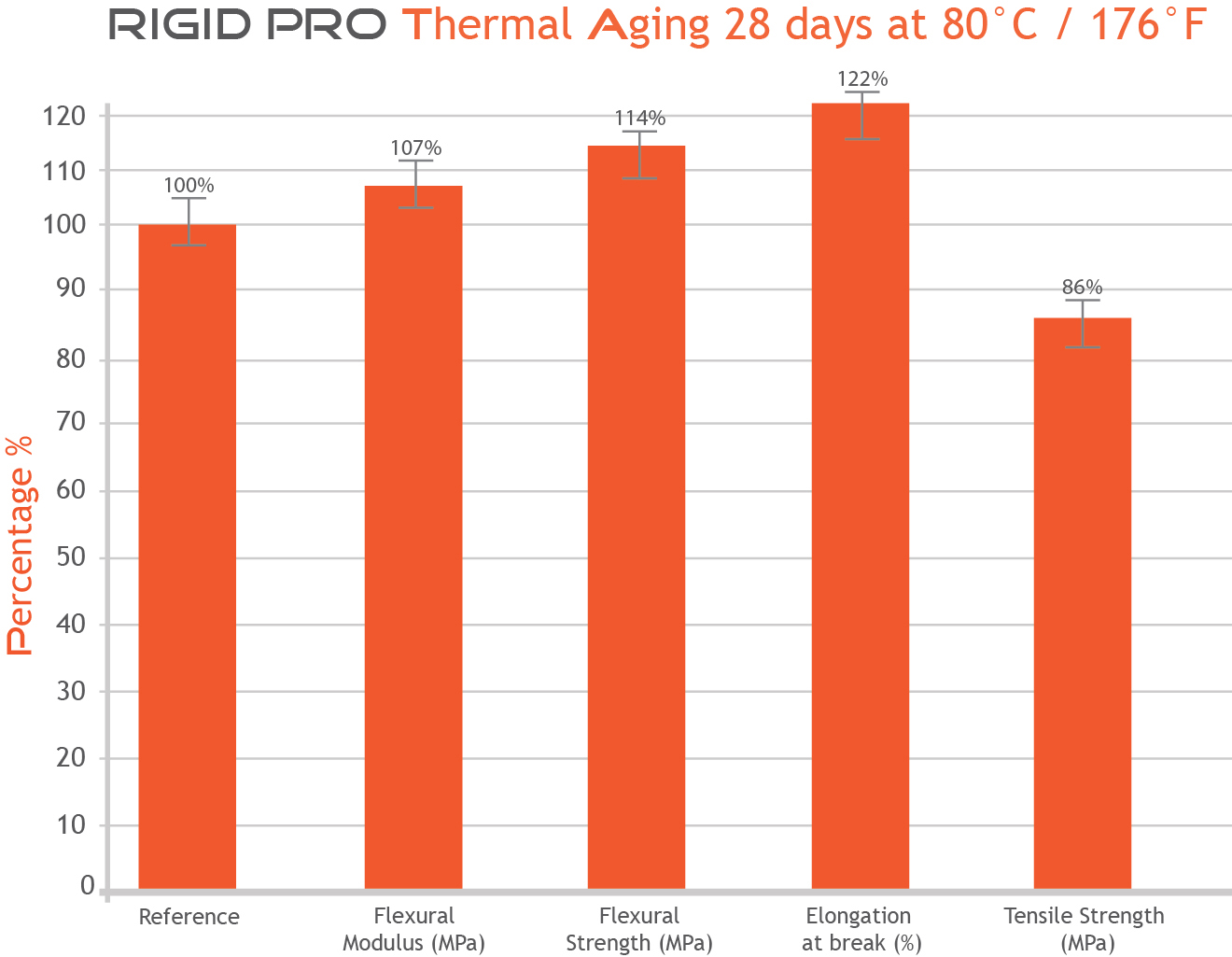

Properties of Rigid Pro after thermal aging

The mechanical properties of Liqcreate Rigid Pro were measured after 28 days of thermal aging at 80°C / 176°C. The reference was scaled at 100% and deviation compared to the reference are published below.

If there are any questions or remarks, feel free to contact us at info@liqcreate.com any time.

3D-PRINT resin Aging

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!