3D-printing resins are known to be brittle materials. It can be experienced that objects break easily. This brittleness comes from the many cross-links and stiff back-bone of the resin formed during 3D-printing. During exposure, the polymerization process starts and is linking all monomers together, forming a highly cross-linked and stiff resin network. Tough materials are required for a lot of applications, making resin manufacturers like Liqcreate push the boundaries and creating new chemistries to develop 3D-printing resin suitable for demanding applications. The search for suitable applications is not only focused on SLA and DLP but also on LCD / MSLA 3D-printing technology. In this blog we are providing an overview of the different commercial available tough resins and explain Liqcreate engineer’s vision on ABS-like materials. All data is obtained from the official manufacturers resin datasheet and the sourced are copied below.

What is a tough 3D-printing resin?

When searching through the internet, you can find a lot of resins called tough resin. In this blog, resins without a technical data sheet (TDS) were not taken into account. It is important to note that this is not a top-down list with the best resin on top. All materials have different characteristics, where one resin has a higher impact strength, another resin excels in the higher elongation and a third resin could have the most balanced properties. It is important to assess all properties before selecting a resin that fits your application best. This brought the Liqcreate engineers to the following list of tough resin for 3D-printing anno November 2020:

| Resin Manufacturer | Notched IZOD Impact [J/m) | Flexural Modulus [GPa] | Elongation at break [%] |

| Liqcreate Premium Tough[1] | 43 | 1,0 | 20 |

| Liqcreate Tough-X[2] | 72 | 0,4 | 150 |

| Liqcreate Clear Impact[3]

|

29

|

1,7

|

25

|

| Formlabs Tough 2000[4] | 40 | 1,9 | 48 |

| Formlabs Tough 1500[5]

|

67

|

1,4

|

51

|

| DSM Somos Taurus[6]

|

47,5

|

2,0

|

24

|

| EnvisionTEC ABS Tough[7]

|

15,5

|

2,5

|

3,5

|

| Carbon3D RPU 70[8] | 15 | 1,5 | 100 |

| Carbon3D UMA 90[9]

|

30

|

1,2

|

30

|

| 3D-Systems Figure 4 Tough BLK 20[10] | 27 | 1,65 | 36 |

| 3D-Systems Accura ABS White[11]

|

24 – 57

|

2,1

|

8 – 14

|

| BASF Ultracur3D ST80[12]

|

17

|

1,7

|

21

|

| Henkel Loctite 3172 [13] (HDT40 High Impact Clear) | 43

|

1

|

141

|

Looking for a tough ABS-like 3D-printing resin?

Almost all 3D-printing resin manufacturers are trying to mimic ABS and some market their resin as ABS-Like. Why is ABS the benchmark and how does its properties compare to best in class tough resins?

ABS (Acrylonitrile Butadiene Styrene) plastic is a thermoplastic polymer often processed by injection molding and FDM 3D-printing. It is one of the most common plastics used in part production manufacturing and 3D-printing[14].

ABS is relatively safe to handle as it cools down and hardens, making it one of the easiest plastics to handle, machine, paint, sand, glue, or otherwise processed. Other benefits of products made of ABS plastic include:

- – Excellent Impact resistance / tough

- – Good heat resistance

- – Good Tensile Strength

- – Scratch resistant

- – Low Cost

Just like 3D-printing resins, there are many different blends of ABS available, making it difficult to give one set of properties to the group of ABS materials. In this case the properties listed are from the technical data sheet of LG Chem’s HF380[15] general purpose injection molding grade ABS:

Tensile Strength 44 MPa ASTM D638

Tensile Modulus 2,1 GPa ASTM D638

Elongation at break 10% ASTM D638

Izod Impact Notched 245 J/m ASTM D256

HDT (at 1,82 MPa) 85ׄC ASTM D648

Matching these properties with the selection of tough 3D-printing resins displayed above, you can find materials with similar or even exceeding strength, modulus (stiffness) and elongation, but the impact strength of 245 J/m is still far from matched. As resin technology moves into a more mature phase, we expect that these properties can be reached within a couple years.

For the engineers among us, this is an interesting read, were you can see how the properties of ABS change when parts are 3D-printed with FDM technology.

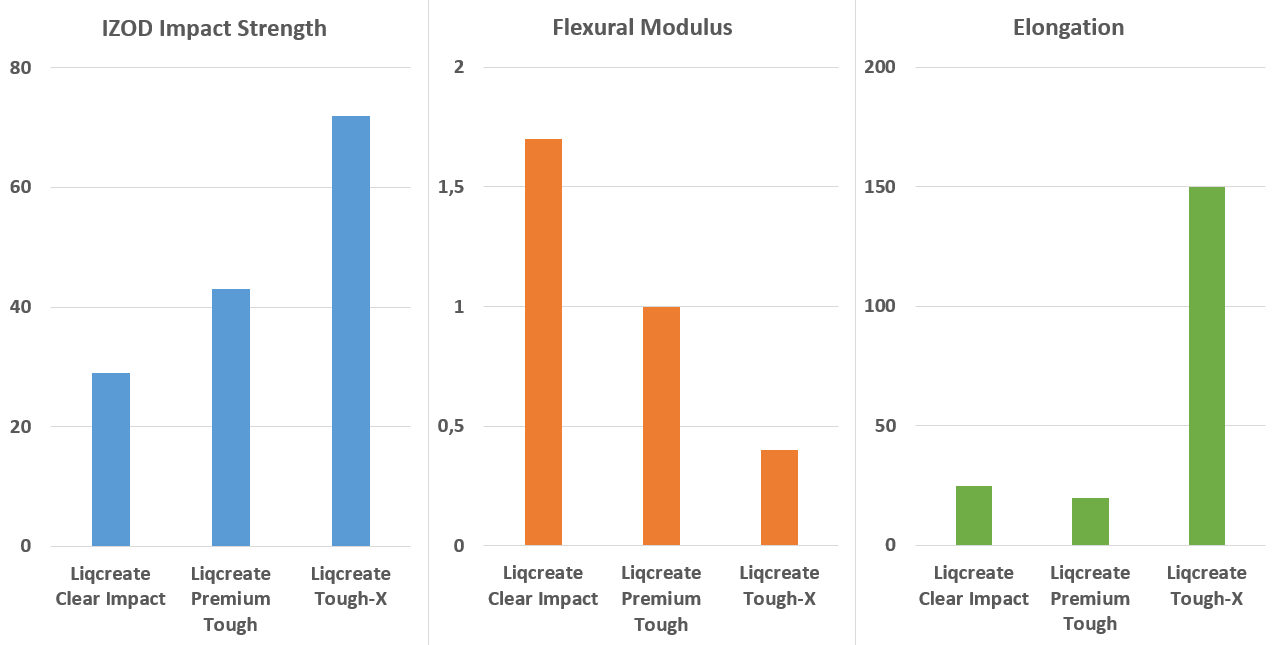

What is the difference between Liqcreate Clear Impact, Tough-X and Premium Tough 3D-printing resin?

At Liqcreate, we regularly get the question what the difference is between the 3 tough photopolymers we offer. Focused on reactivity, Premium Tough resin is more suitable for low-powered DLP and MSLA / LCD 3D-printers, while Tough-X and Clear Impact have a lower reaction speed, ideal for SLA, laser based and high power DLP printers. With the recent advancements in monochrome LCD displays, Tough-X and Clear Impact are easier to print in MSLA printers as well.

If you look at the mechanical properties, these three materials are completely different. Clear Impact is a more rigid kind of tough resin, also with the lowest impact strength among the Liqcreate tough resins. This resin is ideal if your application requires still some temperature resistance and should be fairly hard. Premium Tough resin is softer and less stiff compared to Clear Impact. This resin exhibits a great balance in impact strength and stiffness, ideal for use below 48 degrees Celsius. Tough-X is an even softer and less stiff resin compared to both earlier mentioned resins. With an elongation of up to 150% and exceptionally high impact strength, it is the go-to resin for extreme impact applications. This resin is less suitable in warm environments or applications were a certain modulus / stiffness is required. The property differences are explained by the graphs below.

Send an e-mail to info@liqcreate.com if you have additional questions about the Liqcreate materials.

Are these tough resins compatible with my resin 3D-printer?

Let’s talk about 3D-printer compatibility of the above mentioned tough resins. Hardware manufacturers like 3D-Systems, Carbon3D, EnvisionTEC and Formlabs focus on selling their hardware with their materials and their resin are not known to be compatible with other 3D-printers. To our best knowledge the DSM Somos resin is compatible with (huge) laser based SLA 3D-printers brands like UnionTEC[16], RPS[17] and Stratasys[18]. While Henkel is an open platform, mainly working with high-end brands like Asiga[19], RapidShape[20], Genera3D[21], Origin[22], Nexa3D[23] and NewPro3D[24]. At the time of writing the only public information on BASF is that they are working together with Photocentric[25]. Time will tell how all these manufacturers move forward in resin 3D-printing. For those who follow Liqcreate, know that the resin formulators at Liqcreate aim for a wide resin compatibility with DLP, SLA, MSLA and LCD 3D-printers in all segments. More information regarding machine compatibility can be found here. Just to name a few Liqcreate compatible 3D-printer brands:

- – Sprintray Moonray S & D DLP 3D-printing[26]

- – Formlabs Form 1+ and 2 SLA laser based 3D-printing[27]

- – Atum3D DLP Station 5[28]

- – Asiga DLP Series[19]

- – Miicraft 125 DLP 3D-printing[29]

- – Anycubic Photon LCD MSLA series[30]

- – Elegoo LCD and MSLA series[31]

- – Phrozen LCD and MSLAseries[32]

- – Peopoly LCD / MSLA and SLA series[33]

- – And many more

Send the team of Liqcreate an email at info@liqcreate.com for any questions or more information about resin, 3D-printing or anything else. In behalf of Liqcreate we wish you happy 3D-printing!

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Materials →

Clear Impact

Liqcreate Clear Impact is an optically clear photopolymer for SLA and DLP technologies in the range of 385 – 405nm. Parts created with Liqcreate Clear Impact are perfectly transparent, slightly flexible and have an excellent impact resistance. The high toughness of the material makes it ideal for the production of functional parts which are repeatedly exposed to stress. Low water absorption and weather resistance makes it perfect for outdoor applications.

Key benefits |

3D-Printer compatibility |

| · Optically clear | · Asiga Max and Pro 4K |

| · Excellent impact resistance | · Formlabs Form2 |

| · Good chemical resistance | · Sprintray Moonray S & D |

| · Low yellowing | · And many more |

Tough-X

Liqcreate Tough-X is an opaque black photopolymer. 3D-printed parts from this material have exceptional durability. Liqcreate Tough-X is easy to use on all open source DLP, LCD and SLA 3D-printers in the range of 385 – 420nm. This material has excellent properties like high impact strength and up to 150% elongation, making it perfect for the production of industrial spare parts and functional tough and hard-rubber replacement products.

Key benefits |

3D-Printer compatibility |

| · Exceptional Impact Strength | · Epax3D Series |

| · High Elongation | · Phrozen3D Series |

| · Rigid rubber properties | · Elegoo & Anycubic Series |

| · Heavy Duty | · And many more |

Premium Tough

Liqcreate Premium Tough is a tough and impact resistant resin for Liquid Crystal Display (LCD) and Digital Light Processing (DLP) 3D-printers. Liqcreate Premium Tough is perfect for manufacturing functional prototypes that require toughness and durability. Liqcreate Premium Tough is a transparent resin which turns into a beautiful milky white polymer during polymerization. The high impact strength and exceptional scratch resistance of Liqcreate Premium Tough makes it perfect for the functional prototypes and industrial spare parts.

Key benefits |

3D-Printer compatibility |

| · High Impact Strength | · Elegoo Series |

| · Exceptional scratch resistance | · Phrozen3D Series |

| · Durable | · Anycubic Series |

| · LCD and MSLA compatible | · And many more |

Literature list

1] www.liqcreate.com/product/premium-tough/

2] www.liqcreate.com/product/tough-x/

3]www.liqcreate.com/product/clear-impact/

4] www.formlabs-media.formlabs.com/datasheets/2001340-TDS-ENUS-0P.pdf

5] www.formlabs-media.formlabs.com/datasheets/Tough_1500_TDS_EN.pdf

6] www.dsm.com/content/dam/dsm/additive-manufacturing/en_US/documents/Brand-Status-Sell-Sheets/English-Letter/Somos%20Taurus%20SS-PDS%20Letter.pdff

7] https://envisiontec.com/3d-printing-materials/micro-materials/abs-tough/

8] https://docs.carbon3d.com/files/technical-data-sheets/tds_103213-02-a_rpu-70.pdf?_ga=2.97812253.341763551.1603010655-810967969.1599203870

9] https://docs.carbon3d.com/files/technical-data-sheets/tds_103525-02-a_uma-90.pdf?_ga=2.135550003.341763551.1603010655-810967969.1599203870

10] www.3dsystems.com/materials/figure-4-tough-blk-20

11] www.3dsystems.com/sites/default/files/2017-02/3D-Systems_Accura_ABS_White_SL7810_DATASHEET_A4_01.22.17_UKEN_WEB.pdf

12] www.crea3d.com/en/basf-resins/817-basf-ultracur3d-st-80-resin-1kg.htmll

13] www.loctiteam.com/wp-content/uploads/2020/08/3172-HDT40-High-Impact_Clear_pTDS.pdf

14] www.retlawindustries.com/Info/ABSPlastic

15] www.lgchem.com/product/PD00000013

16] www.uniontech3d.de

17] www.rps.ltd

18] www.stratasys.com

19] www.asiga.com

20] www.rapidshape.de

21] www.genera3d.com

22] www.origin.io

23] www.nexa3d.com

24] www.newpro3d.com

25] www.photocentricgroup.com

26] www.sprintray.com

27] www.formlabs.com

28] www.atum3d.com

29] www.miicraft.com

30] www.anycubic.com

31] www.elegoo.com

32] www.phrozen3d.com

33] www.peopoly.net