Liqcreate Premium Model is perfect for manufacturing dental models and aligners models. This photopolymer is a matte, opaque skin / peach colored dental resin. Its matte color accentuates depth and detail in your dental model, which accommodates a perfect view on undercuts in 3D-printed models. Its good temperature resistance supports vacuum forming for aligner manufacturing.

3D-printed parts from this material have exceptional dimensional stability and low shrinkage during printing. Premium Model and printed objects of Premium Model should not be used for applications inside the human body. Liqcreate Premium Model prints fast and is easy to use on open MSLA / LCD and DLP 3D-printers in the range of 385 – 420nm. If you have any questions, reach out to us at info@liqcreate.com and our technical team will assist.

The following topics are covered in this article:

- Shake before use.

- 3D-printing parameters.

- Shrinkage and offset parameters (for creating high accuracy models)

- Dies / insert won’t fit in dental models

- Support settings.

- Cleaning, washing and post-curing your part.

- How to clean/filter the resin?

- Patterns in resin during/after printing.

- Minimum wall thickness for hollowing models.

- Part orientation, over-hang & drain holes.

- Part surface finish or sticky surface.

- Ideal resin printing temperature.

- Solving print failures.

- Storage conditions.

- Additional information.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Technical →

1) Shake before use.

For most resin, shaking for a couple minutes is advised, especially after long storage to get a homogeneous mixture before printing. Same goes for Liqcreate Premium Model. Shake for a couple minutes and let the resin rest for a couple minutes before using. During shaking the resin is homogenized, but some air bubbles will be present. If you start a print job right after shaking, air bubbles might be present in the first layers of the part. Just before starting a new print, wipe the bottom of the resin tank quickly with a soft spatula to make sure the resin is homogenized before printing.

2) 3D-printing parameters.

Liqcreate Premium Model 3D-printing resin is designed for open compatibility on 405nm and 385nm DLP, MSLA, LCD and laser-based resin 3D-printers. It is important that the 3D-printer is open for 3rd party resins and parameters can be changed. A lot of parameters are already prepared and listed on our website. Click on your actual printer to see if Liqcreate Premium Model parameters are available. If that is not the case, send an e-mail to our technical team at info@liqcreate.com and they will try to help.

3) Shrinkage and offset parameters.

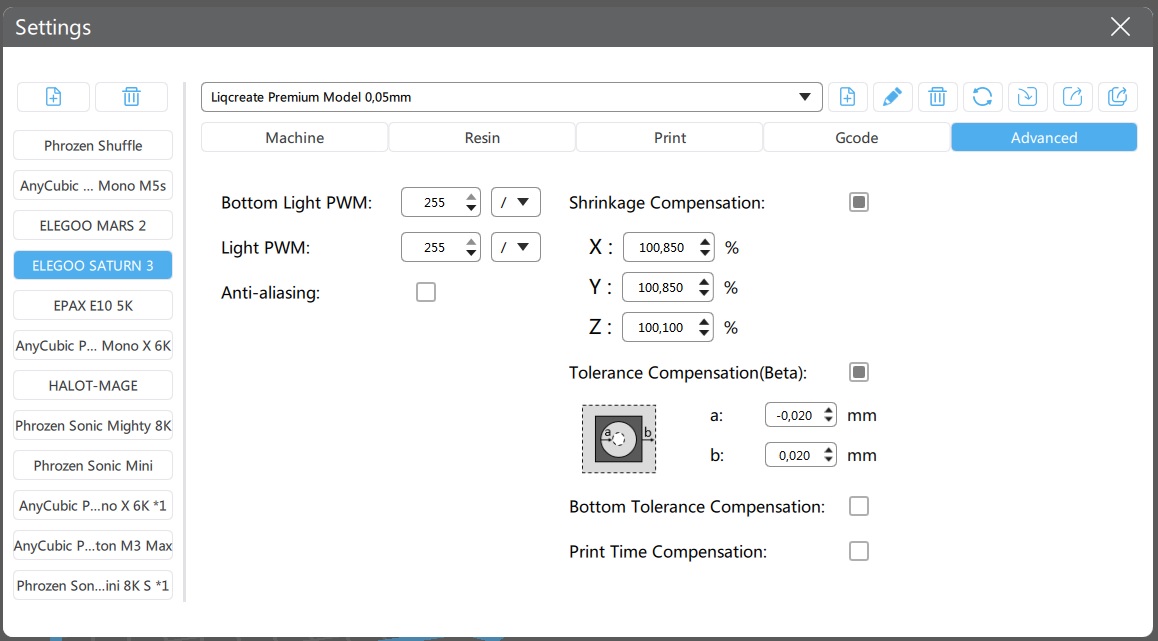

To get the needed accuracy for dental models, it is advised to add a shrinkage compensation and off-set. All 3D-printing resins will shrink during 3D-printing and post-processing. When you don’t compensate for this, the model might be 0,5% smaller then the STL file. For dental applications it is therefore advised to use the shrinkage and offset compensation. This can be different for each printer. below you can find the printers that have been tested. if your printer has not been tested, send us an e-mail and we will assist. Here you can find our resin 3D-print shrinkage optimization database per printer! This is how shrinkage optimization parameters look like in Chitubox for Premium Model on the Elegoo Saturn 3. With the shrinkage compensation and tolerance compensation you can create accurate models.

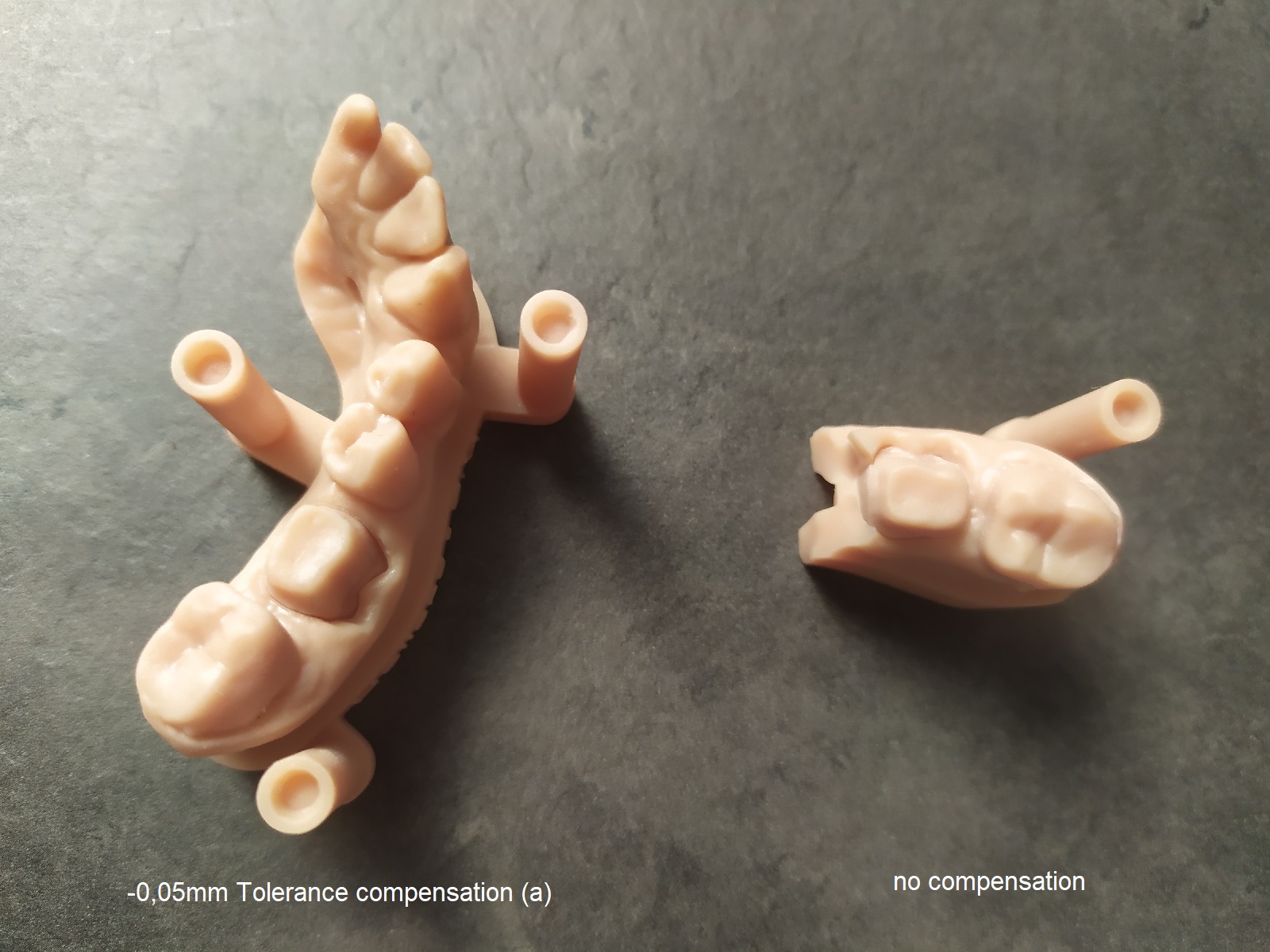

4) Dies / insert in the dental model won’t fit

To start with, best accurate die-fitting models you will get from our Dental Model Pro in Beige or Grey. With default settings of the LCD or DLP, the dies don’t always fit nicely and might be too tight or too loose. In the example below the dies fit too tight and the model breaks if you push the die in completely. by adding an offset / tolerance compensation of -0,05mm at the “a-value” only. the die gets extra room in the model to fit nicely without changing the outer dimensions of the die. on the right picture below the die doesn’t fit with the standard settings while the the offset is applied to the model on the left. Contact us at info@liqcreate.com if you need help with this for Liqcreate resins.

5) Support settings.

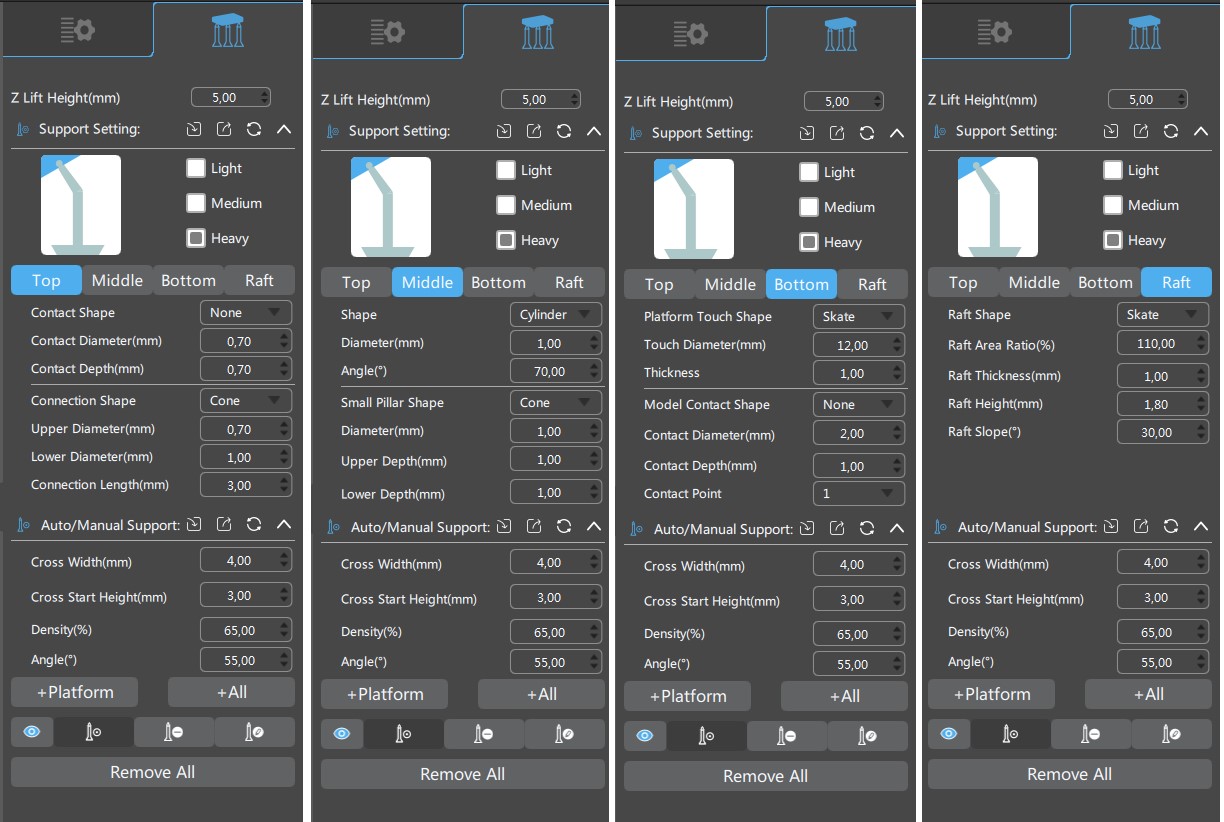

Support settings are depending on the type of resin in combination with the type of printer, release mechanism, material on the bottom of the resin tank and also the secondary settings like print speed. With the extreme growth of available resin 3D-printers in the past years, it is impossible to give validated support settings for each printer. In this section you can find settings for some generic printers, design and print speed. We tested a standard design with different settings. If your part is more bulky / large cross-section for each layer, then the support tip thickness or intersection might need to be increased. For dental mogels there are a few preferred configurations:

Image: Test parts to optimize support settings.

Image: Test parts to optimize support settings.

Support settings on the Saturn 3 were successfully validated for this part and can be found below. In chapter 6 we explain how to orient and to minimize large bottom surfaces. We tested a standard design with different settings. If your part is more bulky / large cross-section for each layer, then the support tip thickness or intersection might need to be increased.

Image: support settings of Premium Model with our generic test parts, tested on the Elegoo Saturn 3 resin 3D-printer.

6) Cleaning, washing and post-curing your part.

Washing is similar to other Liqcreate resins. wash in either IPA, Ethanol or Liqcreate resin cleaner. For resin cleaner the cleaning instructions on that webpage can be used. For IPA and Ethanol they can be used in an ultrasonic cleaner or cleaner with agitation (like the new low cost Anycubic / Elegoo washing unit). Preferably 2 times 2 minutes washing cycle. For the best result the second wash should be performed in fresh IPA / ethanol. If there are small cavities that are not cleaned by this method, then use a soft brush to clean them out and wash in fresh solvent again for 1 minute. Then let the part dry for 30 minutes. Before post-curing, inspect that the part is dry and completely free from solvent (no shiny resin spots on the surface). Otherwise wash again in fresh solvent for 1 minute. Do not wash for longer than necessary as parts can deform when exposed to IPA / Ethanol for >30 minutes when not fully cured. Also be careful if your parts are thin (<2mm) and the IPA in the ultrasonic cleaner is warm (>30°C / 86°F), parts can warp. If you notice this, either make the parts thicker or wait until the temperature of the IPA is below 30°C / 86°F.

When small holes and tight corners are difficult to clean, then brushing with a soft brush is advised to clean these specific areas. After brushing, rinse in fresh IPA / ethanol to get all resin leftovers cleaned. For Premium Model curing in a heated curing unit is preferred, but not necessary. Best UV post-cure method is for 30 minutes at 60°C / 140°F in a 385-405nm curing unit. We have also seen good results with entry-level curing units for 30 minutes at room temperature. Extended post-curing information and settings for different curing units can be found in this link.

7) How to clean / filter the resin?

When a part failed during printing, it is always advised to clean your resin tank. This is usually done by filtering the resin to make sure all rigid plastic pieces are gone. If cured resin parts are present when you start a new print, they can damage your FEP film of even your LCD screen. A standard resin filter will work sufficiently to filter Premium Model resin.

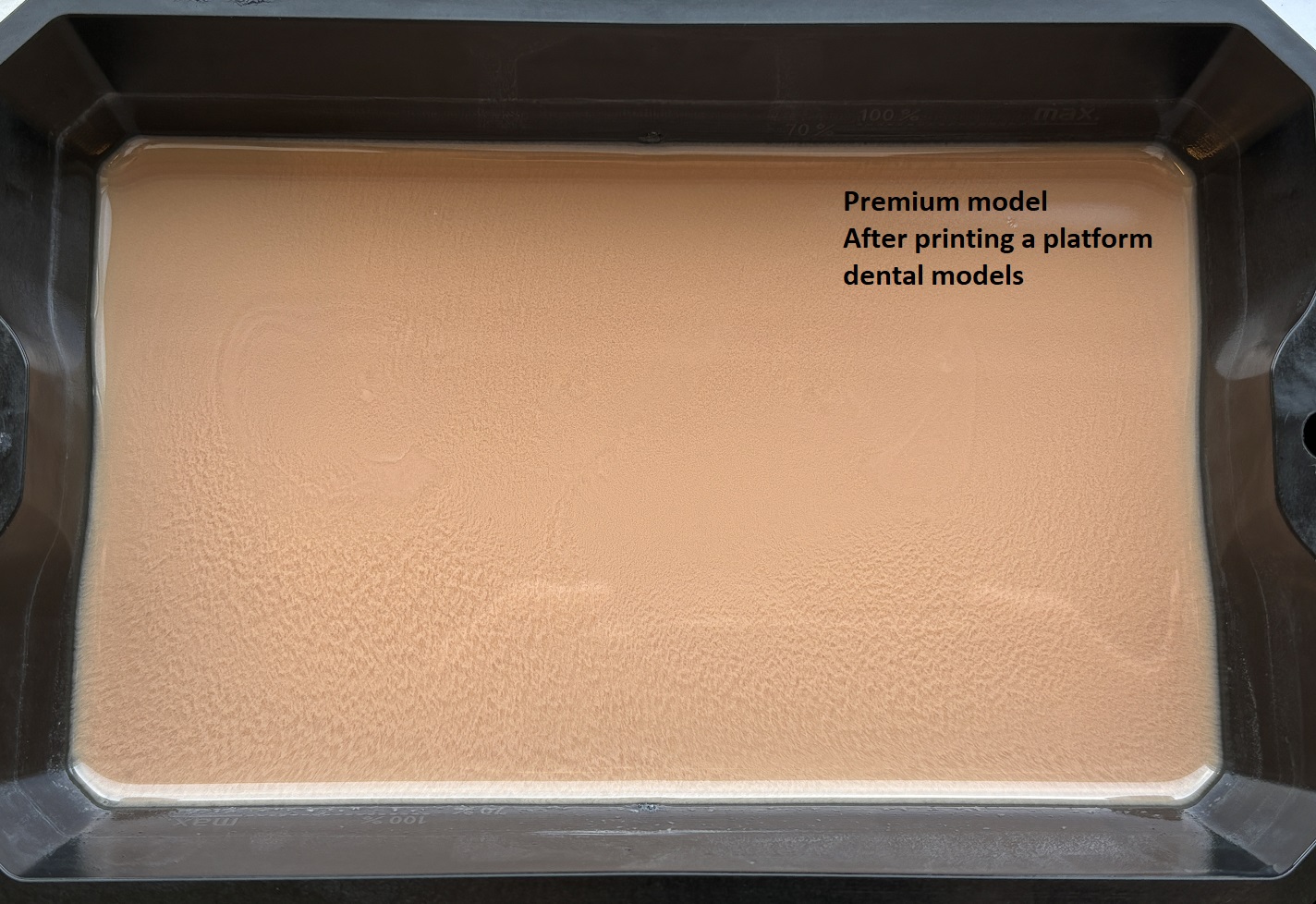

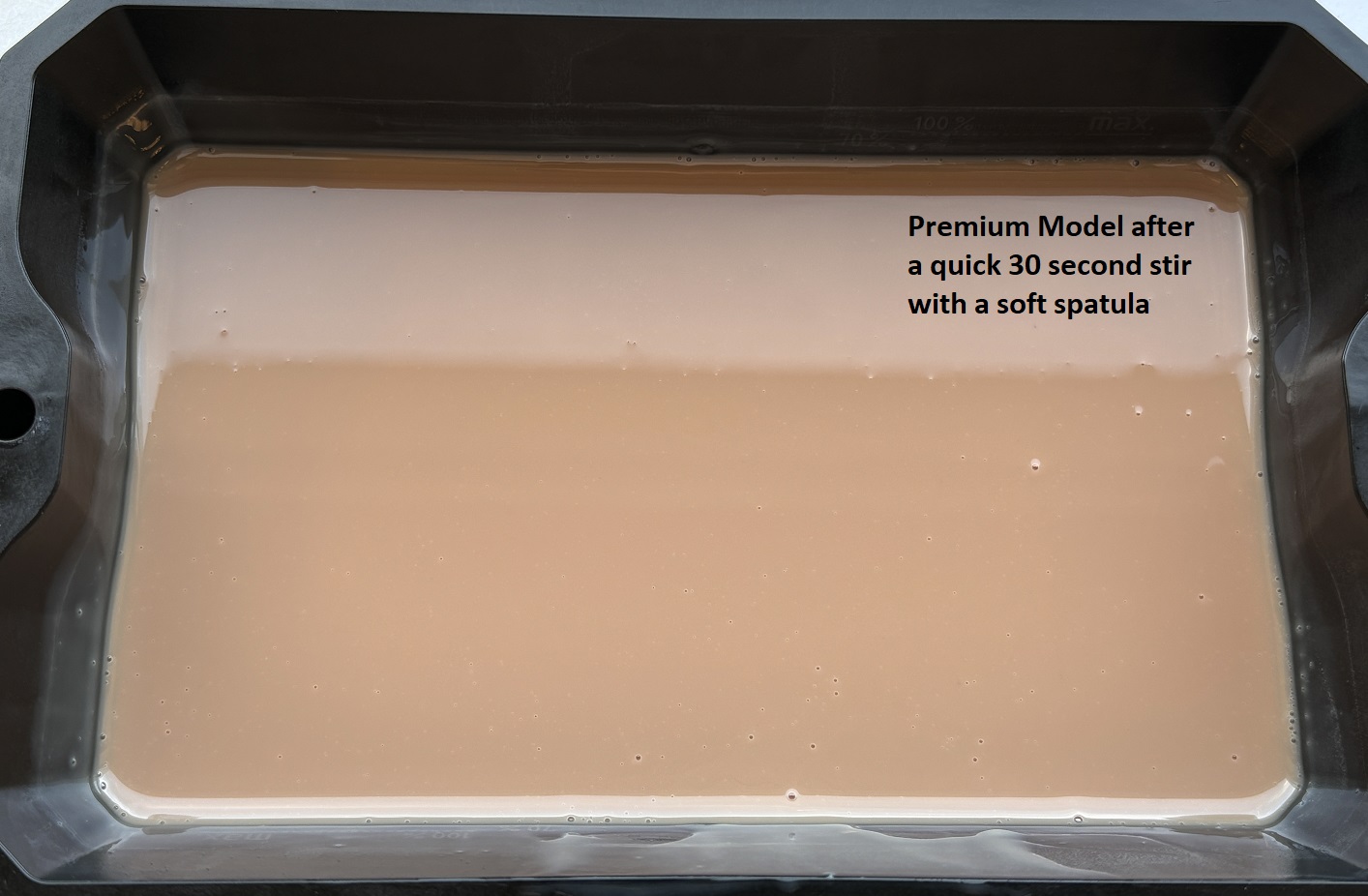

8) Patterns in resin during / after printing.

Liqcreate Premium Model resin is stabilized. However, after a print or in very warm areas, there can be some de-mixing of the pigments in the resin. This effect is stronger over a longer period of time or when the temperature is higher. In some LCD based printers, the printer itself generates a lot of temperature during printing, accelerating this effect. For printing an ideal temperature of 20-25°C / 68-77°F is recommended. As the resin is stabilized this should not have an effect on your printed part. It is advised to mix the resin with a plastic spatula before running a new print. A quick stirr of 30 seconds is sufficient! Alternatively, try to keep the resin at or below 25°C / 77°F if possible. External heating above 20°C / 68°F is not required and can lead to unwanted acceleration of de-mixing. After a print job or long waiting time in the printer this resin pattern is completely normal.

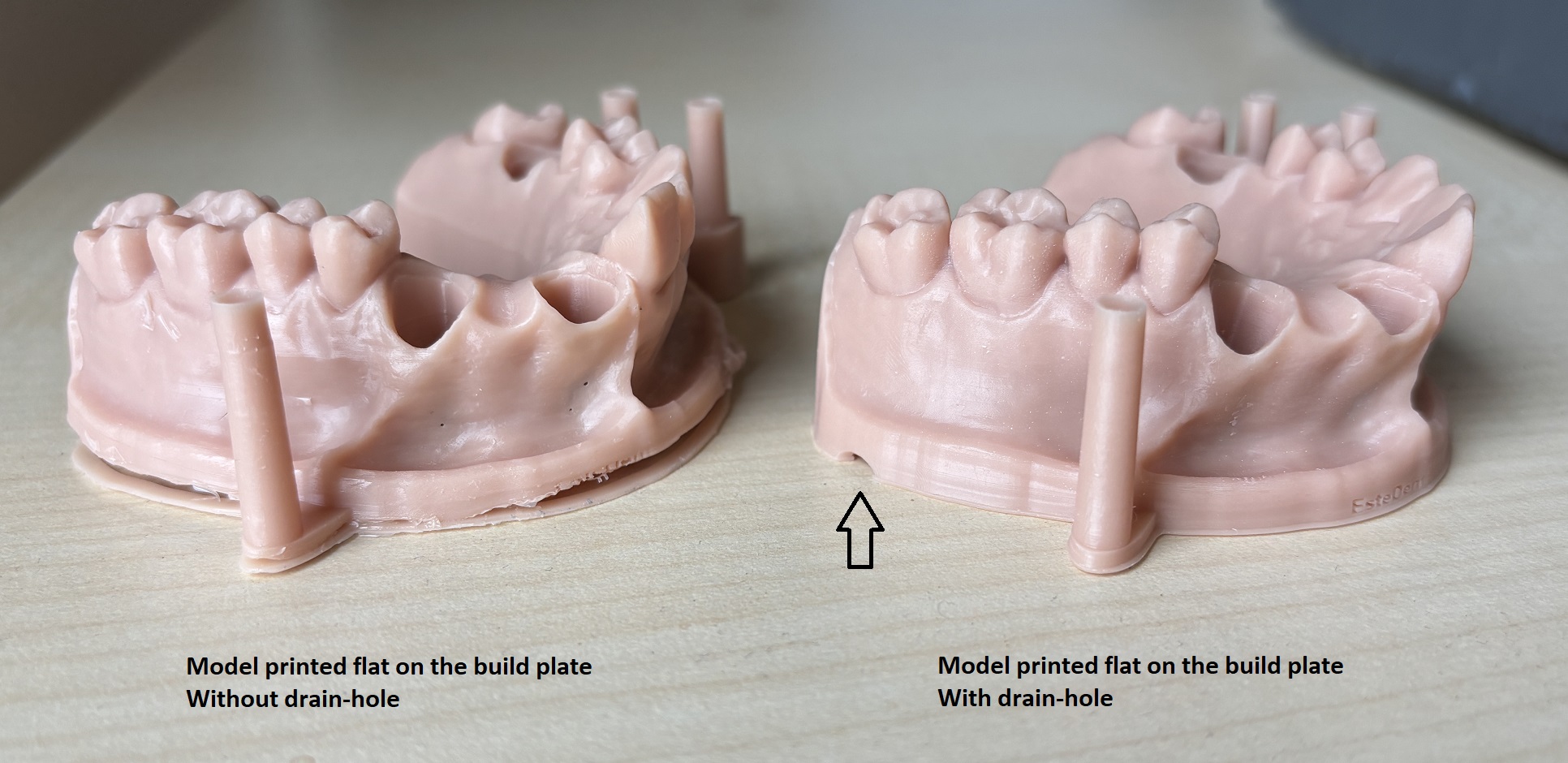

9) Minimum wall thickness for hollowing models.

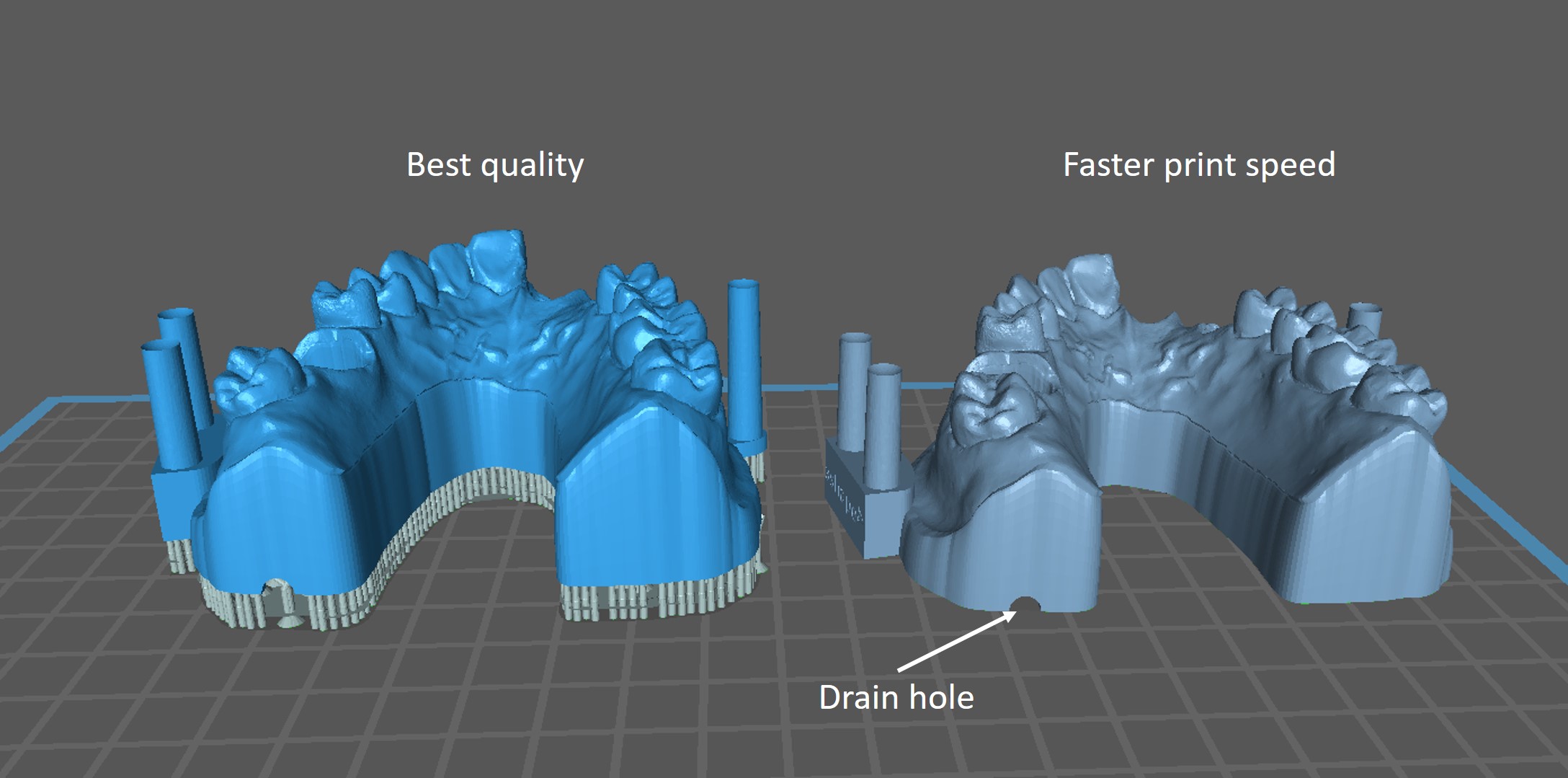

When prionting dental models it is always advised to print them hollow. Next to saving in resin costs, it is also easier to print high quality models when they are hollow. The reason behind this is that for solid models, the printer has to expose a large area at once. This will generate quite some heat and too much heat might cause extra curing on the sides of the model. So for quality reasons and economical reasons it is good to make the models hollow. Advised average wall thickness for hollow dental models made with Liqcreate Premium Model is 2 – 3 mm. Next to this it is advised to add a “drain” hole near the base or in the base of the model. A few of these holes are needed to relief pressure inside the model when you print directly on the build plate. This has a major influence on part quality as you can see in the comparison below.

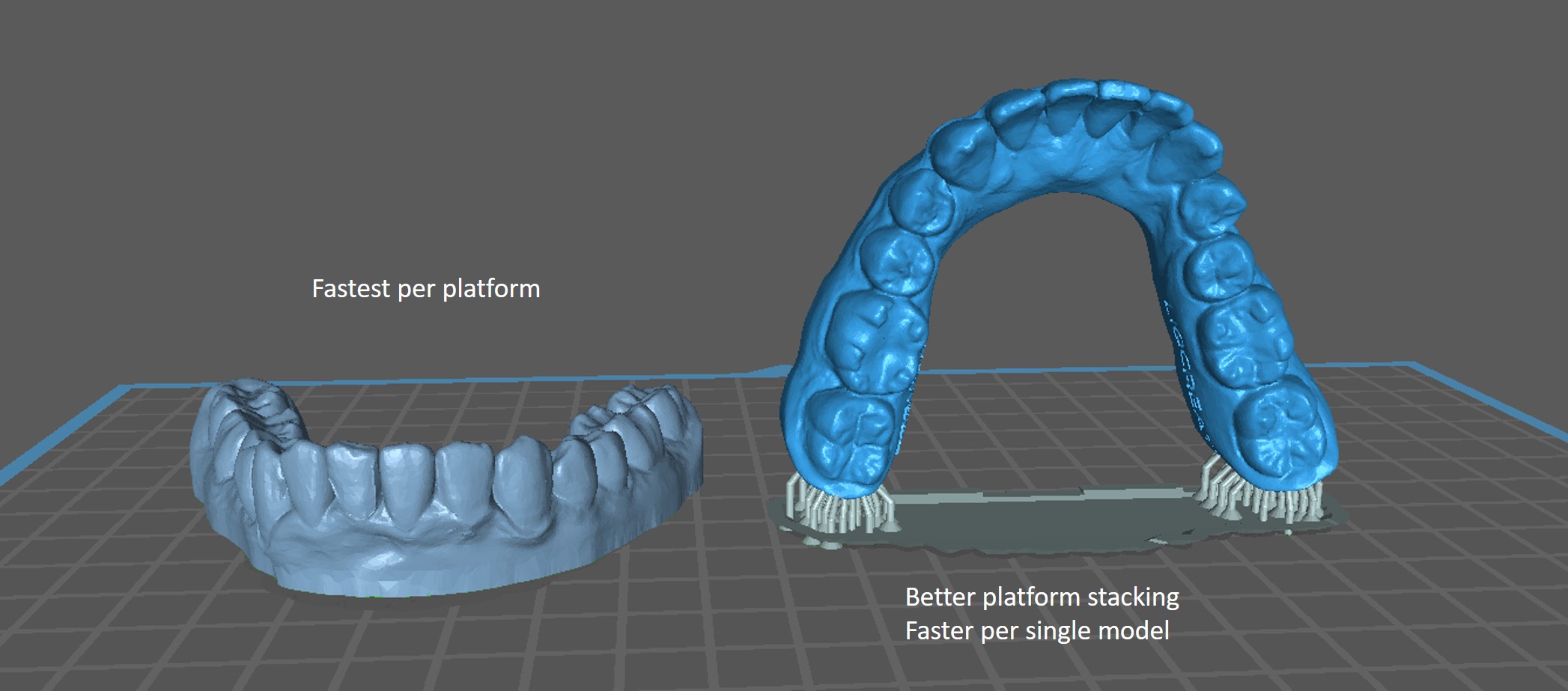

10) Part orientation, over-hang & drain holes.

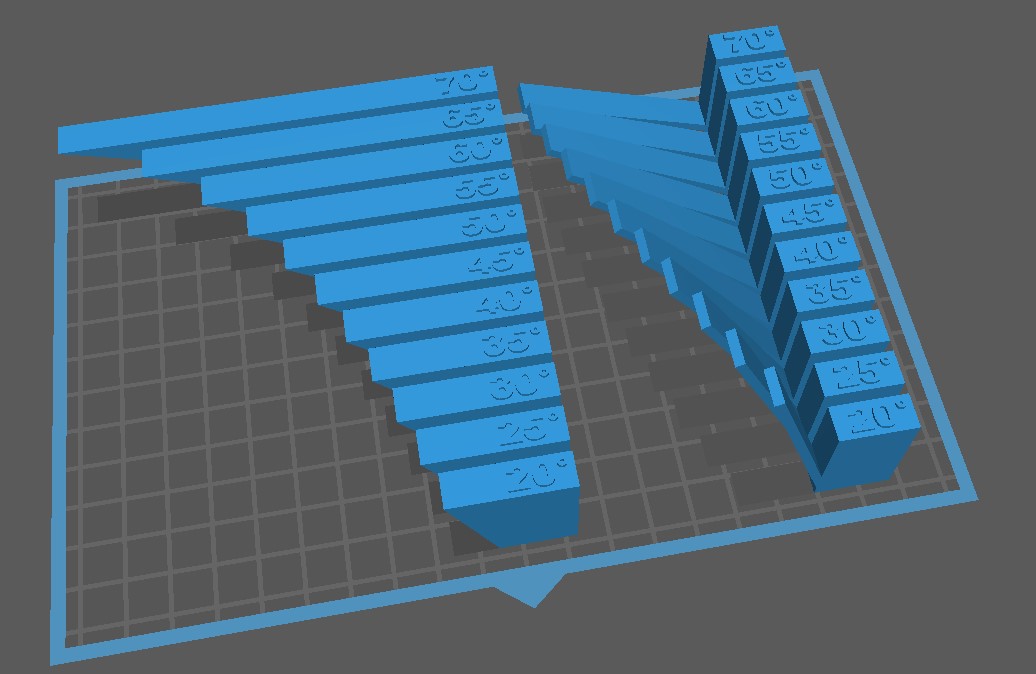

It is not advised to print large and relatively flat parts on supports. if possible, always print at an angle to prevent large bottom surfaces as the quality when printing in an angle is much better. In this test we printed a part from Thingiverse and also made a modification on it to see at which angle the parts can be printed. The thingiverse file was rather solid, while our own modification had a wall thickness of 2.0 mm.

Image: Testing printing angle with the Thingiverse (Thing 40382) file and a small modification of it with thinner walls (2.0 mm).

Image: test to print at different angle without supports with Liqcreate Premium Model resin.

It is possible to print 2mm thick walls in Premium Model at an angle of 70 degree. However, the bottom surface will be better when supporting parts with an angle above 50 degree.

11) Part surface finish or sticky surface.

Printed parts from Liqcreate Premium Model are opaque and shiny during printing. A semi-matte surface will appear after washing and drying as in the picture below. Parts can be polished or coated to get a glossy surface finish.

12) Ideal resin printing temperature.

It is advised to print with Liqcreate Premium Model resin at at 20°C / 68°F and maximum at 25°C / 77°F. printing at lower temperature causes random failure in the material. Excessive heating can lead to faster de-mixing of the resin and is not advised.

13) Solving print failures with Liqcreate Premium Model resin.

There are a lot of common resin 3D-printing issues. In this article you can find 10 common resin 3D-printing fails and how to solve them. If you have need support, send is an e-mail at info@liqcreate.com and our technical team will try to assist.

14) Storage conditions.

Store the product in its original bottle, plug and cap at minimal 5°C / 41°F and maximum 30°C / 86°F. Avoid sources of heat, radiation, static electricity, sunlight and contact with food.

15) Additional information.

- – Product information

- – List of compatible 3D-printers

- – Printer settings

- – Shrinkage optimization parameters

If you have any questions when working with Liqcreate Premium Model or any other Liqcreate resin, send us an e-mail at info@liqcreate.com.

Premium Model

Liqcreate Premium Model is a matte, opaque skin/peach colored photopolymer. Its matte color accentuates depth and detail in your dental models, which accommodates a perfect view on undercuts in 3D-printed models. 3D-printed parts from this material have exceptional dimensional stability and low shrinkage during printing. Liqcreate Premium Model is easy to use on open LCD and DLP 3D-printers in the range of 385 – 420nm. This material has excellent properties like low shrinkage and low odor, accuracy and dimensional stability, making it perfect for the production of resin 3D-printed dental models and aligner models.

Key benefits |

3D-Printer compatibility |

| · Excellent dimensional stability | · Asiga series |

| · High detail | · Shining3D Accufab-L4D |

| · Temperature resistant for aligner | · Phrozen & Anycubic series |

| production | · And many more |

| · Low shrinkage |