The Atum3D DLP station 5 is a high power DLP 3D-printer and completely open for 3rd party resins. Settings for the Atum3D 3D-printer are optimized for Liqcreate resin Deep Blue, Stone Coal Black, Strong-X, Composite-X, Premium White, Tough-X, ESD, Bio-Med Clear, Rigid Pro and Hazard Glow. The 3D-printing parameters can be found in the Atum3D Slicing software.

About the Atum3D DLP Station 5

With its purpose-built, the Atum3D DLP Station 5 has a high-power 405 nm light source and 100 micron x,y resolution optics. Atum3D DLP Station 5-405 resin 3D-printer offers new levels of speed, accuracy and consistency. Its redesigned, industry grade consumables offer a convenient and fast workflow. Additionally the Atum3D DLP Station 4 is a truly open platform for third party resins, allowing customers to choose a 3D-printing resin to fit their application and requirements. The Atum3D DLP Station 5 is a state-of-the-art machine offering both exceptional value and cost-efficiency.

| HIGH SPEED PRINTING

The powerful LED light source in the Atum3D DLP staion 5 offers high build speeds, while the large build envelope allows combining multiple parts in a single run – without impacting build speed. |

CONSISTENT ACCURACY

Integral expertise allows us to optimise part preparation. which ensures consistent, highly accurate and detailed results and truly round openings in any direction. |

| UNPRECEDENTED VERSATILITY

With 50 or 100 micron versions available, Atum3D DLP Station 5 -405 resin 3D-printer fits your accuracy needs and is compatible with a range of Liqcreate 3D-printing resins. |

OPEN PLATFORM

The Atum3D DLP station 5 is truly open platform for third party resins, thanks to the Atum3D Operator Station software and our Resin Tray with a very high chemical resistance and proprietary coating. |

| CONVENIENT CALIBRATION & OPERATION

Calibration of the Atum3D DLP station 5 resin 3D-printing is a breeze with Build Platform S featuring single point fixation and a replaceable build plate. |

INTUITIVE, CONNECTED & SUPPORTED

Use the touchscreen interface and USB port or the optional LAN interface to control Atum3D DLP Station 5 -405, which offers optional support for Autodesk® Netfabb® software. |

| FITS YOUR SPACE

Atum3D DLP Station 5 is designed for side-by-side operation. It’s available as a compact Desktop model or can be raised to optimal working height with the optional Base. |

EXTENSIONS TO MAKE YOUR LIFE EASY

Automate and speed up post-processing with our Curing Station and Extentions, which save a lot of time and effort in an integral process. |

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Printer Settings →

Find Atum3D DLP station 5 compatible resin

Hazard Glow

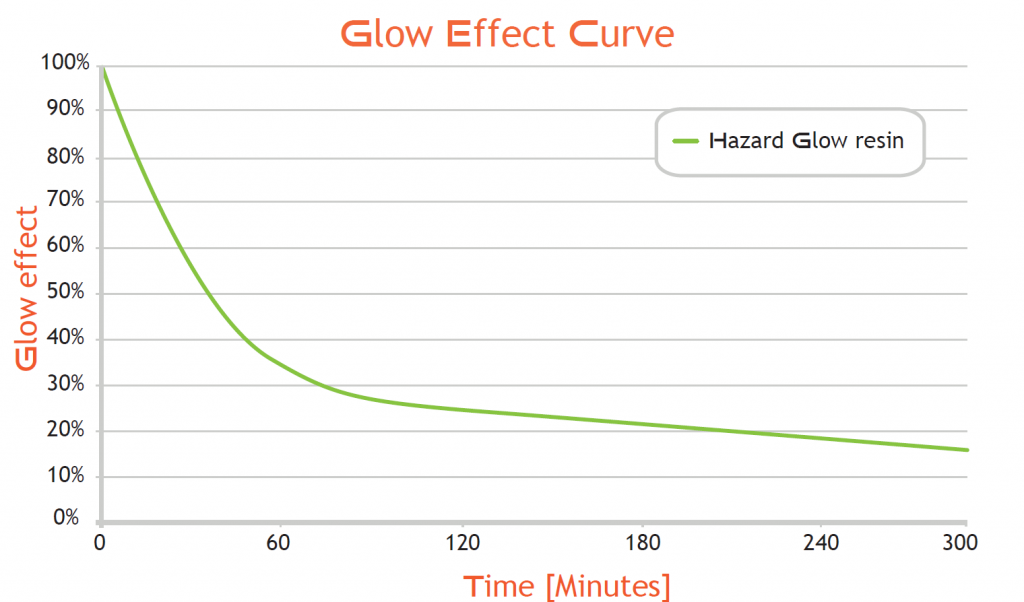

Liqcreate Hazard Glow is the first ever glow-in-the-dark material for SLA and DLP technologies in a range of 385 – 405nm and compatible with the Atum3D DLP station 5. This material is optimized in having the highest possible glow-effect while remaining easy processable in DLP and SLA 3D-printers. The polymers from Liqcreate Hazard Glow can be activated with almost every light source. It has especially a high glow effect when illuminated by a high amount of UV-light, like UV-curing units and sunlight or even by a smartphone flashlight. Its beautiful glowing effects makes this material perfectly suitable to 3D-print a high variety of creations that deserve to be seen when the darkness strikes.

Key benefit

· Upto 4 hours glow effect · Rechargable in any light · ideal for outdoor applications · Smooth surface finish · Low odor |

Stone Coal Black

Liqcreate Stone Coal Black is an opaque high resolution general purpose photopolymer for SLA and DLP technologies in the range of 385 – 405nm and compatible with the Atum3D DLP station 5. The polymer has an incredibly smooth surface finish which highlights the smallest details. Its rigid character makes this material perfectly suitable for rapid prototyping and product development in a wide variety of industries.

Key benefit

· Smooth surface finish · High accuracy · Low odor · Low shrinkage · Opaque resin |

Deep Blue

Liqcreate Deep Blue is a general purpose photopolymer for DLP and SLA technologies in the range of 385 – 405nm and compatible with the Atum3D DLP station 5. Parts created with Liqcreate Deep Blue have a rigid character and its low shrinkage and high shape retention make this material perfect for the production of functional prototypes. The aesthetically pleasing blue color, low odor and overall properties make the material perfect for rapid manufacturing and prototyping in the prosumer market.

Key benefit

· Smooth surface finish · High accuracy · Low odor · Low shrinkage · High translucency |

Liqcreate Strong-X

Liqcreate Strong-X is one of the strongest materials available in the market and is compatible with the Atum3D DLP station 5. Its flexural strength of 135MPa is comparable to industry’s leading dual-cure cyanate ester resins. Liqcreate Strong-X is easy to use on all open source SLA and DLP 3D-printers in the range of 385 – 405nm and only requires UV post-curing. This material has excellent features like high strength, high stiffness and high temperature resistance which makes it ideal for injection molding and heavy duty applications.

Key benefit

· High strength · High temperature resistance · Low odor · Low shrinkage |

Liqcreate Composite-X

Liqcreate Composite-X is an extremely rigid and high performance reinforced nano-micro composite resin for SLA, DLP & LCD / MSLA in the range of 385 – 420nm and compatible with the Atum3D DLP station 5. Perfect for rapid tooling, wind tunnel testing, medical modeling and industrial applications.

Liqcreate Composite-X is one of the stiffest and strongest material available in the market. It has a flexural modulus over 9000 MPa and a flexural strength of 150 – 170 MPa. The material can be used after UV-post curing, or the properties can be boosted with a thermal cure. This material has features like excellent chemical resistance, high strength and high stiffness.

Key benefits |

|

| · High rigidity | |

| · High strength | |

| · Low odor | |

| · Good chemical resistance | |

| · Extremely low shrinkage |

Image by atum3d: A full insole made with 3D-printing resins Liqcreate Tough-X on the Atum3D DLP Station 5

Image by atum3d & de3dprintman: A demonstration of a watch band made with 3D-printing resins Liqcreate Flexible-X on the Atum3D DLP Station 5