Currently over 17 Liqcreate resins are commercially available. These high-end photopolymer resins are used in a wide range of industries including prototyping, industrial, entertainment, consumer goods, healthcare, dental, aerospace and automotive. Even though a lot of resins are available, we sometimes get questions about adjusting the colors or coloring resin. For bigger volumes, we offer custom development, OEM, Private label and white label possibilities.

Although we do not stimulate customers to mix or color resins, sometimes there is no other solution. When you just need a couple kilogram resin, it is difficult to customize a product and take it to production. Therefor some of our customers started asking questions about coloring resins. Mostly to color Premium Tough, Clear Impact and Premium Flex. All three products are already translucent so technically it should be possible to color them with the right colorants. Properties of the resin can change when using colorants, like pigment stability, print speed and mechanical properties. In this article we tested four different 3D-printing resin colorants and resin dyes from 3DJake in our Premium Tough, Clear Impact and Premium Flex resins.

Image by 3DJake, commercial resin dyes for resin 3D-printing

Warning when coloring 3D-printing resins

It should be noted that we at Liqcreate are not in favor that our customers are coloring resins. Although for very low volumes, it is not possible to develop or produce a formulation. If the volumes are increasing, contact us to see if we can manufacture the resin formulation in our factory. There are several reasons to have the resins mixed in a factory, and some points of attention if you decide to mix the resins yourself.

First of all, when working or mixing resins, always wear the right personal protection equipment. This information and more safety information can be found in the safety data sheet (SDS) of the resin. Also work in a well ventilated area. Before coloring resins, make sure that the original resin is shaken properly. If resin or colorant is not homogeneous before mixing, it is almost impossible to duplicate results. Next to this, make sure that the weighing instrument is calibrated and accurate.

Experimenting with colorants for 3D-printing resins

Two resins were selected for this experiment, Liqcreate Premium Tough and Liqcreate Clear Impact. Both resins are clear. Premium Tough will change in a milky white polymer upon curing, while Clear Impact remains colorless. Both materials should be easy to color, due to the natural color of the polymers itself. Three main points of focus will be:

- – Are the pigments stable for longer prints?

- – Are the mechanical properties influenced by the colorant?

- – Is the print speed significantly reduced by the colorant?

Four 3D-printing colorants were selected and ordered from 3DJake:

- – Deep Black

- – Light Grey

- – Transparent Blue

- – Transparent Red

For the test purpose, the maximum recommended loading level of 2,5 weight percentage was chosen and tested. Right after weighing the liquids colorants in the resin, it was apparent that the colorants are very compatible with both Liqcreate resins and are easy to mix in, by just shaking the resin bottle with colorants for a minute.

Mechanical test specimen were printed on an Elegoo Mars 2. Simultaneously the optimal exposure time for 0,1mm layer height was recorded. This was done because coloring resin will likely have an influence on the exposure times.

Table 1: Exposure times of colored Premium Tough resins at 0,1mm layer height on the Elegoo Mars 2

| Resin | Print time (seconds) at 0,1mm layer height |

| Premium Tough | 5,5 sec |

| + 2,5 % Deep Black resin Colorant | 7,0 sec |

| + 2,5 % Light Grey resin Colorant | 7,0 sec |

| + 2,5 % Transparent Blue resin Colorant | 6,0 sec |

| + 2,5 % Transparent Red resin Colorant | 6,5 sec |

As seen from the results above, transparant resin dyes have a slight increase in exposure time on a monochrome LCD 3D-printer like the Elegoo Mars 2. For the opaque resin colorants at maximum loading level, an additional 1,5 seconds was needed to cure a layer of 0,1mm. Please note this could be different for each printer. On printers with an RGB screen, the increase in exposure time is expected to be significantly higher.

Pigment stability of colored Premium Tough resin

When we develop a colored resin at Liqcreate, we always stabilize the resins in order to prevent pigment sagging and settling as much as possible. When adding resin colorants from unknown chemical nature into a clear and unstabilized resin, it is always difficult to predict the outcome. The stability tests was performed during and after the 3D-printing process in the Elegoo Mars 2. We printed mechanical test specimen, which took about 7 hours. After that we waited for 17 hours so the total time the pigments could settle was about 24 hours. The bottom of the resin tank was inspected after this time. Some minor sagging was found for the black and grey pigment. This did not influence the 7 hour print, as the part quality was great. For the blue and red colorants, no sagging or settling was seen within the teste time-frame. In general the stability is good and at least 7 hour print jobs are no problem. Likely longer prints are possible as well.

Picture of the bottom of the resin tank of Premium Tough with 2,5w% Deep Black resin colors collorant after 7 hours printing and totally 24 hours waiting time. Minor pigment sagging was seen, which did not influence the 7 hour print.

Colors of modified Premium Tough resin

The resin colors are displayed below after mixing in all tested resin dyes at their maximum recommended loading level of 2,5%. Premium Tough has a milky white base (left in the picture), which makes the translucent blue and red colorants also semi-opaque. Both the grey and black colorants are opaque and mixing these in Premium Tough also resulted in grey and black opaque polymers.

Colors of 3D-printed parts with additional resin colors colorant. From left to right, Premium Tough, Light Grey, Deep Black, Translucent resin dye Blue and translucent resin dye red.

Colors of 3D-printed parts with additional resin colors colorant. From left to right, Premium Tough, Light Grey, Deep Black, Translucent resin dye Blue and translucent resin dye red.

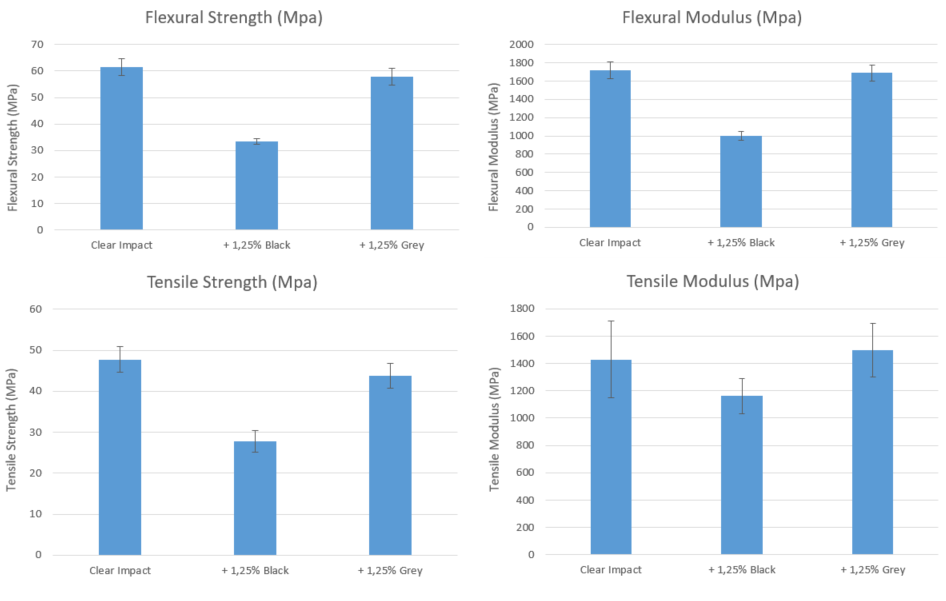

Mechanical properties of colored Premium Tough resin

The mechanical properties of Premium Tough resin and additional colored samples were measured. More background information on mechanical properties can be found in this article. Parts were post-cured in a Wicked Engineering Curebox for 30 minutes at a temperature of 60°C / 140°F.

Graphs of mechanical properties of Premium Tough and colorant mixtures, after post-curing for 30 minutes at 60°C in a Wicked Engineering Curebox.

Looking at the mechanical properties, only some minor changes were recorded when mixing Premium Tough with 2,5% translucent blue and red resin. This is the maximum advised loading level by the manufacturer 3DJake. A minor drop in elongation was recorded for both tranclucent colorants. With the opaque Deep Black and Light Grey colorants, the maximum advised loading of 2,5% resulted in a small decrease of almost all properties by roughly 10%. This is likely due to the inside of the part is not fully cured as the opaque pigment block a lot of the light. Because it is just around 10% reduction, the parts could still be used in a lot of projects.

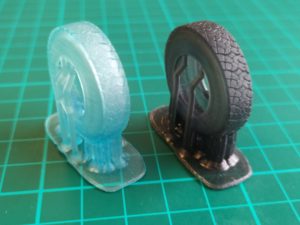

Coloring of Clear Impact resin

Similar tests have been done with Liqcreate Clear Impact resin in combination with resin colorants from 3DJake. In the first tests, a similar colorant loading level of 2,5% was used in Clear Impact. With the opaque pigments Deep Blue and Light Grey, adhesion issues occured at 2,5% loading on the Mars 2 MSLA 3D-printer. First layers were difficult to adhere to the platform with the addition of the pigments. Two changes were initiated after the first tests. The loading level was decreased to 1,25%. Next to that the printer was changed to the Photon Mono SE, as this printer has a aluminum platform, it is easier to get adhesion. After these changes, it prints were looking good at an exposure time of 16,0 seconds, compared to 11,0 seconds for the original Clear Impact resin.

Graphs of mechanical properties of Clear Impact and colorant mixtures, after post-curing for 30 minutes at 60°C in a Wicked Engineering Curebox.

With these tests it can be concluded that opaque colorants are a bit more difficult to process in slower resins like Clear Impact. A longer exposure time was needed, even at 1,25% loading of the colorant in the resin. Properties of the Grey material were quite similar to the original Clear Impact material, while the Black colorant did significantly decrease properties.

Coloring of Premium Flex resin

In the field of radio controlled race cars, we often get requests for an entry level flexible material in black, to mimic tires and other components. The best material for these applications is our Liqcreate Flexible-X. For some applications the properties of Flexible-X are not needed and our more economical flexible resin, Premium Flex is also suitable. In these cases our customers started to color Premium Flex with a black pigment. The technicians at Liqcreate added 1,25% Deep Black pigment sourced from 3DJake in Premium Flex, mixed well and tested it on the Anycubic Photon Mono X 3D-printer. This resulted in a semi-opaque black material, as shown in the picture below. Usually Premium Flex is printed on the Photon Mono X with 6,0 seconds for 0,1mm layers and at 60%UV power. By increasing the UV power to 80% and with the same exposure time, the black Premium Flex resin was printing in good quality. With the addition of 1,25% Deep Black pigment, an additional 20% exposure time is expected for other 3D-printers.

Coloring Liqcreate Elastomer-X

Read all about coloring Elastomer-X in the article in the link.

Coloring Liqcreate Composite-X

Read all about coloring Composite-X in the article in the link.

Additional benefits of coloring 3D-printing resin

Next to appearance, coloring resin might bring other benefits. Opaque pigments and , black, yellow and orange colorants can block the 405nm light during 3D-printing. This will increase the exposure time needed to print, but in most cases also increases the accuracy. By blocking more light during printing, a more defined depth cure for each layer can be reached. This usually results in less through-cure or bleeding and has a positive effect on the accuracy.

Conclusion on coloring 3D-printing resins

The chemists and engineers at Liqcreate were positively surprised how well the tested colorants worked in Premium Tough resin. The stability was quite good and the properties did not change that much after using. The colorants were easy to process. Many other colorants are available in the market. It is impossible to test them all. If they are branded as resin 3D-printing colorant, it is likely that it can work too. Unfortunately only testing these products will tell if it works.

We hoped this was an interesting and educational read. Please send us an e-mail at info@liqcreate.com if you have any questions, comments or remarks. We wish you happy printing and have fun with your colored resin!

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!