We often get the question if DLP printers need special resin. Unfortunately this question cannot be answered with just a yes or no. There are quite some factors that come into play when using different resin 3D-printing technologies. In this article you can find all the technical information why and how a resin works on some platforms (DLP, SLA or LCD) and not on others. It is always advised to contact us if you have questions about compatible resin & 3D-printers.

What is the difference between DLP, SLA and MSLA 3D-printers?

To answer the question, we have to understand what the difference between the 3D-printer technologies DLP, SLA and MSLA are. The long technical comparison between DLP, MSLA and SLA 3D-printers can be found in this article.

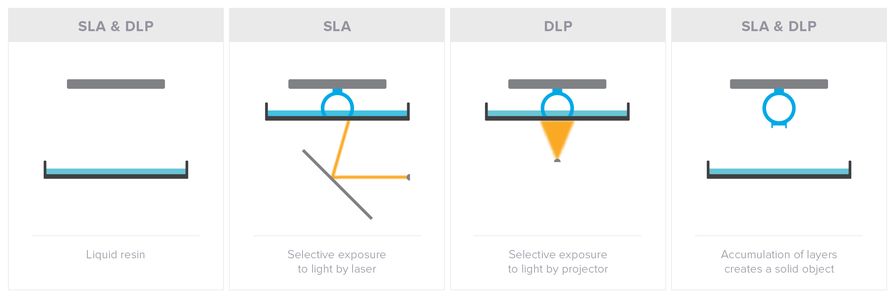

Laser SLA is based on the original invention, used by companies as 3D-systems, Formlabs, UnionTech and Peopoly Moai. The laser is used to selectively cure the resin, by scanning the surface. The resin cures and becomes a hard plastic at the spots where the laser ‘hits’ the resin. DLP-SLA is a technique which uses a projector to selectively cure the resin. It is generally a faster printing technique compared to Laser SLA, due to the fact that the projector can expose the whole layer at once, where a laser has to scan to cure the resin. A few single LED’s are in the center of the DLP projector. The light from these LED’s is guided to a DMD chip, which creates the actual curing pattern. This 3D-printing technique is used by companies like EnvisionTEC (ETEC), Sprintray, Atum3D, Rapidshape and Miicraft

Image by All3DP: different resin 3D-printing techniques explained

MSLA is one of the latest developments in resin 3D-printing , also called LCD based 3D-printing. This technique uses an affordable LCD screen to create the mask, eliminating expensive DMD chips that are used in DLP techniques. This technique works by an array of LED’s illuminating on the LCD. The LCD is used as a mask, which creates the curing pattern. The liquid resin turns into a rigid plastic on the spots where the light ‘hits’ the resin.

Do DLP printers need special resin?

To determine if a resin can work on a DLP printer, it is advised to contact with the resin manufacturer. There are three major factors to determine if a resin can work on a DLP printer. These three major factors are wavelength, the power of the light and if a system is open. Resins are typically designed for a specific wavelength. Most Liqcreate resins work best in the range of 385 nm to 420 nm. Meaning that it can be compatible with DLP systems, laser-based systems and MSLA systems in this range. Often 385 nm is seen in high-end DLP systems while 405 nm is chosen for the more affordable MSLA / LCD-based 3D-printing technologies. The other major factors are the power of the effective light and if a system is open. Usually DLP 3D-printers have a much higher power compared to MSLA / LCD systems. Meaning that the resins specifically designed for these systems react a bit slower to compensate for the high power. Resins like Liqcreate Strong-X, Clear Impact, Deep Blue and Stone Coal Black are designed like this. For high reactive resins like the Liqcreate Premium line, it is often needed to reduce the exposure time significantly or to reduce the power of the light source. For the last option you would need full access to the system.

Can the DLP resins work on SLA and MSLA 3D-printers?

Often the typical DLP resins can work on laser based printers as well. The lasers are usually very powerful and would also require a slower reactive resin to control the 3D-printing process. The LCD-based MSLA printers have a much lower power. These low reactive (DLP) resins can work on MSLA 3D-printers as well, only it has to be noted that the exposure times can be higher.

Which resins can be printed on my 3D-printer?

Our engineers and partners have published information on printer compatibility and printing parameters in this link. If your printer or the resin that you want to use is not listed, or if you have any other questions or comments, please contact us.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!