During 3D-printing the liquid resin polymerize and turn into a solid. If the shrinkage is big it will ruin the dimensional accuracy of your end-part. Ideally you want to limit the amount of shrinkage as much as possible. This could be done by first try to eliminate the most shrinkage by smart material choice. We wrote an article about that earlier. Last thing to do is to optimize your shrinkage and off-set settings in the 3D-printer to compensate of the last bit of shrinkage.

Shrinkage compensation in resin 3D-printing.

Shrinkage compensation is available in most 3D-printer slicers. These settings can be different for each resin/3D-printer combination. We have tested shrinkage compensation factors for a variety of printers and resins. In this articles you will find links to the 3D-printer models and shrinkage compensation values for a variety of resins. This document is updated once new data is available.

Shrinkage Compensation database for resin 3D-printers.

click on the link to find compensation settings for a variety of 3D-printers and Liqcreate resins.

- – Asiga series

- – Raise3D DF2

- – Prusa SL1S

- – Prusa Medical One

- – Uniformation GKTwo

- – Elegoo Mars 3

- – Elegoo Mars 4

- – Elegoo Mars 5

- – Elegoo Mars 5 Ultra

- – Elegoo Saturn 3

- – Elegoo Saturn 4 Ultra

- – Phrozen Sonic Mini 8K S

- – Phrozen Sonic Mighty Revo 14K

- – Phrozen Sonic XL 4K Plus

- – Phrozen Lumii 2K DLP

- – Anycubic Photon M3

- – Anycubic Photon M3 Plus

- – Anycubic Photon M3 Max

- – Anycubic Photon Mono M5s

- – Anycubic Photon Mono M7 pro

- – Anycubic Photon Mono 4 Ultra

- – Anycubic Photon D2

- – Anycubic Photon Mono X

- – Shining3D Accufab L4D

- – Shining3D Accufab L4K

- – NextDent LCD1

- – UNIZ NBEE

- – UnionTech Martrix300

- – UnionTech Martrix520

- – Flashforge Hunter S

- – Flashforge Focus 6K

- – Evodent E128

- – Ackuretta Freeshape

- – Ackuretta Dentiq

Why is there shrinkage in 3D-printing resins?

Shrinkage of acrylates and methacrylates occurs during polymerization. This is caused by the replacement of long-distance connections via Van der Waals force by strong and short covalent bonds between the carbon atoms of different monomer units. The replacement of these long-distance connections with short distance connections, multiplied over millions of bonds are responsible for the overall shrinkage in the material. This happens when the resin changes from a liquid to a solid plastic. This shrinkage can causes serious problems including build-up of internal stress. Internal stress can cause defects formation or dimensional changes, which can be responsible for decreased mechanical properties. It is therefore important to develop and use materials with low shrinkage and control the remaining shrinkage properly.

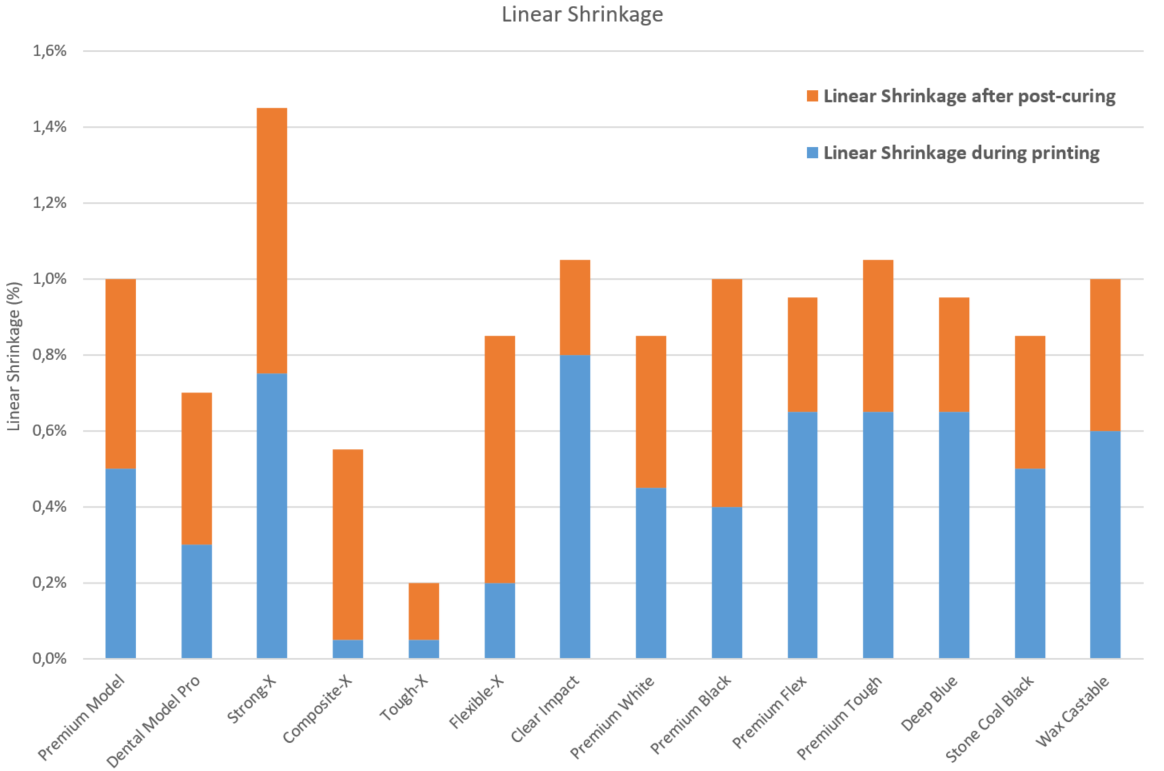

Image: Comparison of linear shrinkage of different Liqcreate resins

How to compensate of shrinkage in resin 3D-printing?

As pointed out earlier, first thing to do is to start with a good low shrinkage resin. This will eliminate all kind of issues later on. Last thing you need to do is to compensate shrinkage in the 3D-printing software settings. As this is a mathematical solution averaged over the complete part. The values might be off when you have a high shrinkage resin. Another factor in this is the type of 3D-printer you are using. Not all entry-model resin 3D-printers have the right compensation options. From Chitubox version 1.9.5 there are XYZ shrinkage (%) settings and tolerance compensation (offset) settings available. A combination of these two settings are often needed to reach the highest accuracy. Team Liqcreate wish you happy printing. If there are any questions or remarks, feel free to contact us at info@liqcreate.com any time.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!