Back in August 2018, Clare Scott from 3Dprint.com wrote an article about 3D-printing affordable medical model. This article was inspired by a paper entitled “Workflow for 3D printing of medical models – phases, timeline and costs,” which was published in “Le Courrier de la Transplantation – Vol. 18 – n 1-2 – June 2018” by Aalto University located in Finland. Learn more how Forma uses 3D-printing medical models with resin.

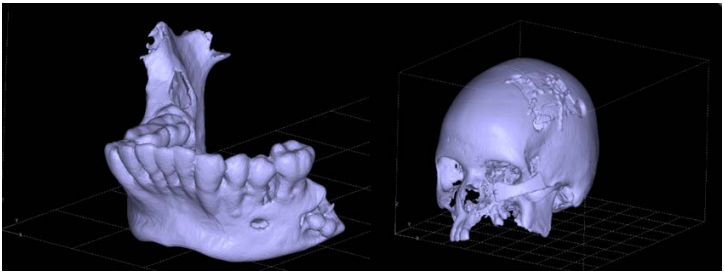

The researchers from Aalto University used CT imaging to model the human skull and jaw bone in this study. After creating several 3D-models, using multiple methods of 3D printing including material extrusion, binder jetting, material jetting processes and resin printing. Every step in the process was described in detail, also how they obtained the images for the models and to render them in 3D. The process is divided into three phases: imaging, 3D printing and medical model preparation or post-processing. Each phase adds time and cost to the entire process, which was carefully calculated by the researchers.

Image: Model DICOM data converted in a STL format, source: Le Courrier de la Transplantation – Vol. 18 – n 1-2 – june 2018

According to Clare Scott from 3Dprint.com “First the medical model DICOM data was obtained from an OsiriX DICOM sample image set, then imported to OsiriX MD 8.0.2 and segmented using 500 Hounsfield unit (HU) to add bone and more dense materials to the 3D model. The 3D file was exported in STL format to obtain the jaw and skull bone geometry.”

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!

Printer Settings →

Pricing of medical model with FDM technology

According to the researchers: “The used 3D printer was uPrint SE Plus (Stratasys Inc, US) with Catalyst EX 4.4 (Stratasys Inc, US) software. The selected layer resolution was 0.2540 mm and model infill was set to ‘sparse’ with high density. Auto orientation was applied for the skull and jaw, as it tries to minimize both building time and material consumption. Support fill was generated using the Smart command. The material was ABS Plus (Stratasys Inc, US) and SR-30 Soluble Support Material (Stratasys Inc, US). The price for the machine is approximately 16 000 €, and the price for both the material and the support material was 200 € per kilogram. The skull model consumed 253.16 cm3 basic material and 223.21 cm3 support material. The jaw model consumed 25 cm3 basic material and 11.78 cm3 support material. The support material can be automatically dissolved away using Wave wash cleaner (Stratasys Inc, US) unit with Ecoworks (Stratasys Inc, US) cleaning agent bags and water.”

Image: Medical models 3D-printed with Liqcreate Premium White resin.

Pricing of medical models with material jetting technology

For material jetting, the researchers have chosen the Objet30 Scholar 3D-printer from Stratasys Inc, with Objet Studio software. According to the paper: “The part was auto orientated in the printer. The material was Verowhite (Stratasys Inc, US) and the support material was SUP705 (Stratasys Inc, US), a gel-like photopolymer. The price for the machine is about 35 000 €, the material price is 280 € per litre, and the support material is priced at 140 € per litre. The simulated thickness was 28 µm with matte finishing. The process requires support material to hold overhanging features and supports are manually washed away with pressurized water with specified washer. The skull model consumed 1402 ml Verowhite material and 2536 ml support material. The jaw model consumed 80 ml Verowhite material and 83 ml support material.”

Pricing of medical model with binder jetting technology

In the category of binder jetting 3D-printers, the researchers have chosen the Zprinter 450 3D-printer from 3D-systems. According to the researcher: “ The material was ZP151 (3D Systems Inc, US) with a layer thickness of 0.1 mm. The orientation was selected to minimize the height of the part, which then results to the fastest building time. Monochrome mode was selected for the printer. The price for the machine is approximately 35 000 €, the material price is 190 € per litre, and unbound material served as a support and can be recycled to make new parts. Supports were removed manually by detaching unbound powder with pressurized air and after that the parts were strengthened by for example dipping them in cyanoacrylate or covering them with two-component epoxies.”

Pricing of medical model with resin (SLA, DLP and MSLA) 3D-printing technology

Unfortunately the researchers have not taken resin (SLA, DLP or MSLA) 3D-printing into account. With incredible technology improvements and price reductions over the past years, this should be the go-to technology for producing a medical model. After converting the model DICOM data into an STL file, any 3D-printing software can process the file to a sliced 3D-printer file. A medical model can be printed in the opaque white resin Premium White, or for more dental related models, Premium Model can be used. With prices far below €100 / kg, both resin will outperform the economics of the above mentioned options easily. Looking at options above were binder jetting is most affordable at a price of €190 / liter, followed by FDM at €200 / kg and most expensive resin material jetting costing €280 / kg for the model material and €140/kg for support(waste) material. Furthermore for functional bone like materials, Composite-X resin could be an interesting material. With its Shore D hardness of D94, it comes close to the hardness of actual bone.

3D-printer compatibilityLearn more about 3D-printer compatibility of Liqcreate resins.

|

Next to pricing, another benefit of using Liqcreate resins for medical modeling is that you are not tied to hardware that comes with the material. For instance with the options mentioned by the researchers, hardware of €16.000-35.000 is required to print the models. Printers compatible with Liqcreate resin come in a lot of forms and price-ranges, thinking about the UnionTech Cute300, industrial 4K DLP printer or the Atum3D, Asiga or entry level Anycubic Photon Mono X to just name a few.

Learn more about Liqcreate resins for medical model

Liqcreate Premium White

Liqcreate Premium White is the most opaque white resin available. This white photopolymer resin has excellent UV-stability, with almost no yellowing upon exposure. Due to its rigidity and high stability it is ideal for the manufacturing of medical and architectural model.

Key benefits |

3D-Printer compatibility |

| · Opaque White | · UnionTech Cute300 |

| · Non-yellowing | · Phrozen & Creality series |

| · Low odor | · Elegoo & Anycubic series |

| · Low shrinkage | · And many more |

Liqcreate Composite-X

Liqcreate Composite-X is an extremely rigid and high performance reinforced nano-micro composite resin for SLA, DLP & LCD / MSLA in the range of 385 – 420nm. Perfect for rapid tooling, wind tunnel testing, medical modeling and industrial applications.

Liqcreate Composite-X is one of the stiffest and strongest resin available in the market. It has a flexural modulus over 9000 MPa and a flexural strength of 150 – 170 MPa. The material can be used after UV-post curing, or the properties can be boosted with a thermal cure. This material has features like excellent chemical resistance, high strength and high stiffness.

Key benefits |

3D-Printer compatibility |

| · High rigidity | · Phrozen3D series |

| · High strength | · Atum3D DLP Station 5 |

| · Low odor | · Elegoo & Anycubic series |

| · Good chemical resistance | · Shining3D AccuFab-L4K |

| · Extremely low shrinkage | · And many more |

Liqcreate Premium Model

Liqcreate Premium Model is a matte, opaque skin/peach colored photopolymer resin. Its matte color accentuates depth and detail in your dental models, which accommodates a perfect view on undercuts in a 3D-printed model. 3D-printed parts from this material have exceptional dimensional stability and low shrinkage during printing. Liqcreate Premium Model resin is easy to use on all open source LCD and DLP 3D-printers in the range of 385 – 420nm. This material has excellent properties like low shrinkage and low odor, accuracy and dimensional stability, making it perfect for the production of dental models.

Key benefits |

3D-Printer compatibility |

| · Excellent dimensional stability | · Asiga Max & 4K Pro |

| · High detail | · Shining3D Accufab D1 |

| · Temperature resistant for aligner | · Phrozen & Anycubic series |

| · production | · NextDent LCD1 |

| · Low shrinkage | · And many more |

Team Liqcreate wishes you happy printing. If there are any questions or remarks, feel free to contact us at info@liqcreate.com any time.