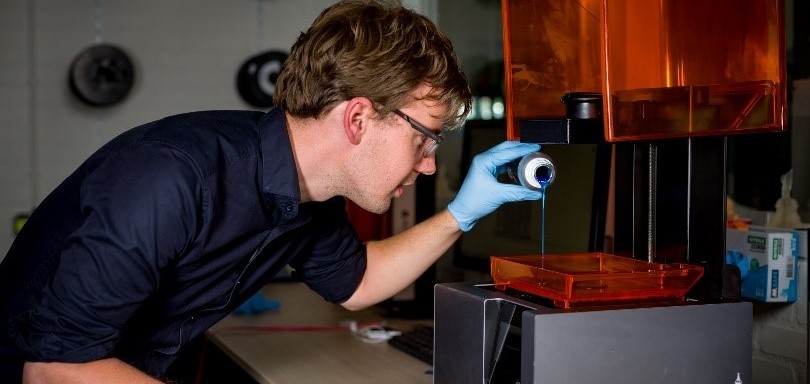

Friday 26 June 2020; In the Green PAC project VitriMore, researchers from NHL Stenden are looking for easily recyclable resins for 3D printing. These polymer resins based on biomass must be re-moldable so that you can use them for injection moulding again after use. ‘With VitriMore, we want to develop recyclable resins for 3D printing,’ says Vincent Voet, associate lecturer in Sustainable Plastics at NHL Stenden. ‘With resin printers, you build up a product layer by layer from resin, which hardens through exposure to light. That is why we call this type of resin a photopolymer resin.’ With laser technology, you can determine exactly where this hardening must take place in each layer. ‘These techniques play an increasingly important role in industrial processes, so the sales of these types of resins are increasing,’ Voet explains. ‘However, current resins are often made from petroleum and are not easily recyclable. After curing, the resin exhibits the behavior of a thermoset and can then normally no longer be melted or recycled.’

In January of this year, the research group published in ‘ACS Applied Polymer Materials’ about photopolymer resins for 3D printing made from soybeans. ‘We did that project in collaboration with the University of Groningen and the company Liqcreate’, says Voet. ‘VitriMore is a follow-up to that in which we also look at recyclability. To improve that, we are looking at the use of so-called vitrimer resin, polymers that form a dynamic network.’ At room temperature, these vitrimers behave like thermosets, but when heated or the pressure is increased, they behave more like a thermoplastic and are therefore remeltable. Voet: ‘Ultimately, we want to use vitrimers based on biomass as a resin for 3D printing techniques. For example, we are working on recyclable bioresins for 3D printing with a low impact on the environment.’

About the VitriMore project

3D printing, or Additive Manufacturing, is increasingly seen as the new industrial revolution. The 3D printing market is expected to grow to a global turnover of 184 billion euros by the end of 2029. In practice, this means that there is an increasing demand for materials to print products with. A considerable part of these materials consists of various types of plastics, including thermoplastic polymers and photopolymer resins. The disadvantage of these plastics is that they are based on petroleum and therefore expensive and limited. With VitriMore, work is being done on the development of sustainable biobased photopolymer resins, as a basis for 3D printing, which are recyclable and contribute to a lower environmental impact.

Characteristics of biobased 3D-print resin

- – Creating a new generation of biobased resins and oligomers (based on e.g. soybean oil, cashew nut shells, shrimp shells and algae) with different functionalities to control the mechanical, chemical and thermal properties;

– Investigating the chemistry around the application of vitrimers (hard, glassy plastics that are recyclable) within the SLA/DLP printing technique;

– Combining the biobased 3d-print resin oligomers into vitrimers that are suitable for application in SLA/DLP printing technique in order to deliver a fully biobased and circular end product.

Advandages of the project for based 3d-printing resin

- – Contribute to the further development of sustainable biobased and circular resins for 3D printing;

– A line of new resins for market applications;

– New knowledge in the field of (bio)polymer chemistry and bio-based 3D-print resin.

Partners for biobased 3d-print resin development

NHL Stenden

Rijksuniversiteit Groningen

Windesheim

Liqcreate

Croda

Arkema Group

More information

Vincent Voet

E vincent.voet@nhlstenden.com

Stenden University: https://www.nhlstenden.com/nieuws/recyclebare-bioharsen-voor-3d-printen

Green PAC: https://www.greenpac.eu/nl/projecten/vitrimore/