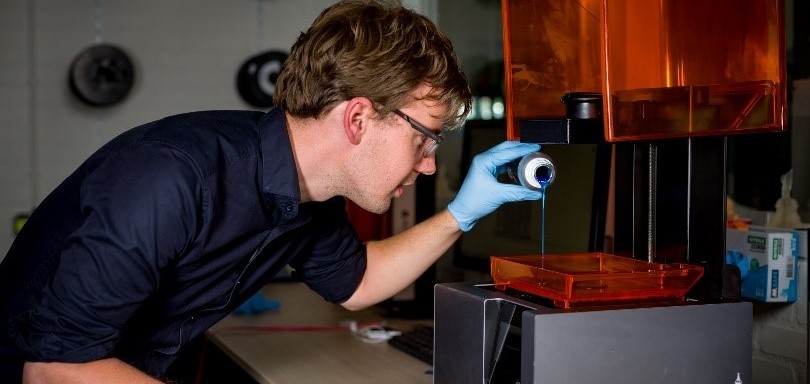

Green PAC and Dutch resin manufacturer Liqcreate have succeeded in developing an SLA and DLP resin based on renewable raw materials, respectively. The first tests yield good results. The material is expected to be available to end users later this year or early next year. Geraldine Schnelting, Materials Scientist at Green PAC in Zwolle, announced this during the 3D Printing Materials conference at Brightlands Chemelot campus. The first batch used soybean oil as a raw material; for the second batch of the biobased resin, other renewable raw materials will be tested.

Growing demand for biobased resins.

According to Geraldine Schnelting, the demand for biobased resin for SLA and DLP 3D printers is growing. This is partly due to the strong growth in interest in these 3D printing techniques, which provide fine detailing and isotropic material properties. “In addition, interest is growing due to the transition to a circular economy,” says the junior researcher at Green PAC. According to her, the new biobased materials are comparable to moulded resins. Initially, they started with an acrylate based on soybean oil. This achieves a percentage of renewable raw materials of 82.5%. According to Schnelting, fully renewable raw materials are something for the longer term. At the moment, they do not want that yet because it creates space to use additives to adapt the properties of the material to the application requirements.

Bio-based 3d-printing resin alternatives.

The first 300 grams of biobased resin was used for DLP printing. Part of the research is post-processing of the 3D printed parts when they come off the DLP printer. As with current resins, based on fossil raw materials, polymerization only takes place for 80% during printing. “We really need post-processing. That is when the isotropic properties of the material are created.” The printed parts are washed with isopranol; UV curing is required for full polymerization. “Post-processing remains important for the mechanical properties.” The transparency and mechanical properties are currently not yet comparable to the current commercially available resins. “Biobased does not yet offer the strength. But it is good that there is an alternative.” According to Geraldine Schnelting, that alternative is especially attractive for prototyping.

Other raw materials for resin 3D-printing and waste streams.

Green PAC and Liqcreate are now going to scale up to produce larger quantities of biobased resins. In the first batch of biobased resin, 300 grams were made. In the next batch, cashew nut shells will be used as the basic raw material to increase the percentage of biobased material. In addition, they are investigating how the properties can be further improved with additives and printer settings. At a later stage, Geraldine Schnelting announced, they will also investigate whether waste streams can be used as a basis for biobased resins. In addition, they are looking at synthetic solutions.

Source 3D print Magazine: About biobased resins for 3D-printing resin from Green Pac & Liqcreate