This article originally appeared on 3Dprintingindustry.com and is slightly altered for our website. Netherlands-based independent 3Dprinting resin developer and manufacturer Liqcreate has added a new ESD safe 3D-printing resin its photopolymer resin portfolio to support 3D printing in the electronics industry. This affordable ESD-safe resin supports electronic manufacturers & service centers to custom manufacture their ESD parts with resin 3D-printing.

Liqcreate ESD is an opaque black photopolymer resin and can be processed on most resin based 3D-printers. 3D-printed parts from this material exhibit electrostatic discharge properties needed for electronic manufacturing and parts for ESD-safe workplaces (EPA). Liqcreate ESD can be used on open DLP, LCD and SLA 3D-printers in the range of 385 – 420nm. Due to the isotropic electrostatic dissipative properties, it is suitable for electronic devices and components that require ESD. Reduce risk and increase manufacturing capabilities by printing custom jigs, fixtures and tools to protect critical electronics components from static discharge.

Key benefits

- – Manufacture cost-effective ESD parts

- – Isotropic ESD properties

- – Well balanced rigidity and impact

- – Antistatic properties

- – Easy to print

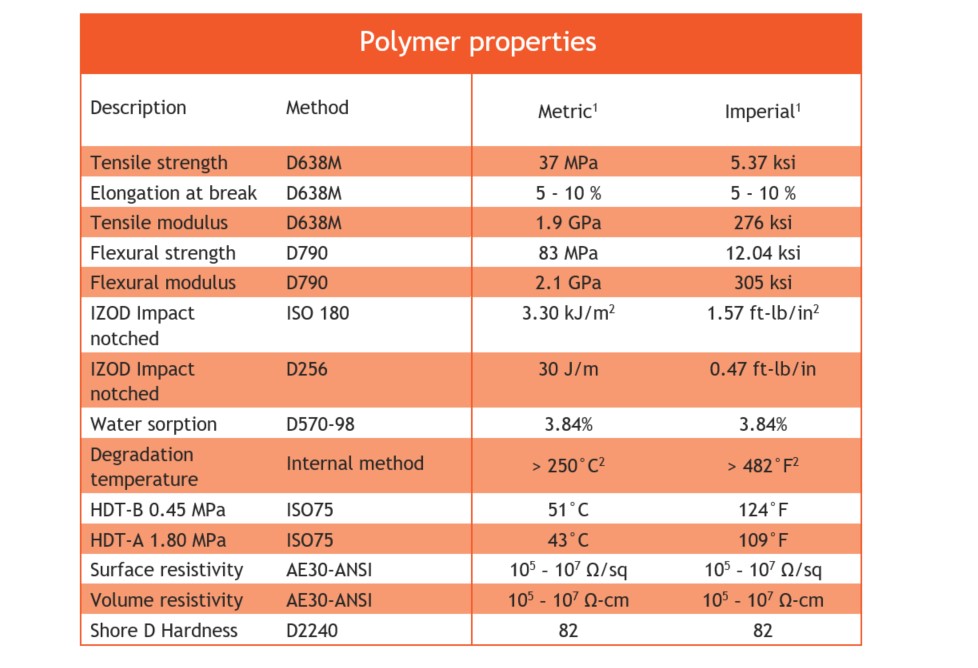

Technical Data of Liqcreate ESD 3Dprinting photopolymer resin

This ESD 3D-printing resin is designed to meet the demands of the electronics and manufacturing industry. Liqcreate ESD resin have been extensively tested by industry experts prior to the release. The material has a rigid nature with some flex and impact resistance. These properties make the material perfect for applications like electronic enclosures and factory tools.

1Post-cured 30 minutes with high power LED curing at 60°C in the Wicked Engineering curebox. These values may vary and depend on individual machine processing and post-curing. 2Material will soften above HDT value but not break/crack up to 250°C without force on the part.

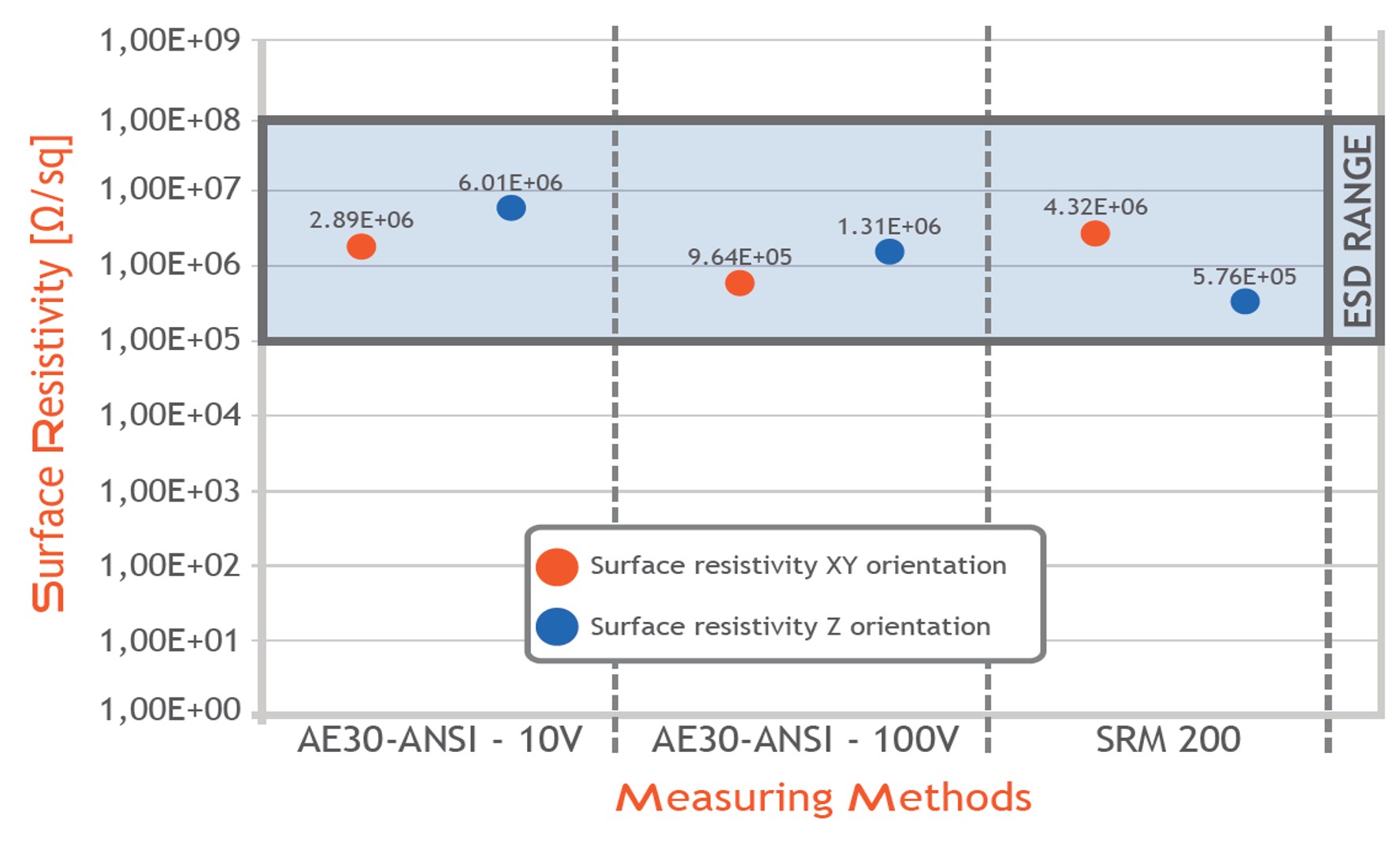

Isotropic ESD properties with resin 3D-printing

The ESD properties were measured by different methods and also in two different 3d-printing directions. AE30-ANSI and SRM 200 measurements on surface resistivity show uniform ESD properties across the part. Additionally the ESD properties are quite similar in different 3D-printing directions. All these values remain well within the ESD range.

Image by Liqcreate showing isotropic ESD properties with resin 3D-printing

3D-Printer compatibility with Liqcreate ESD resin

All Liqcreate resins are designed to use on a broad range of resin based 3D-printing technologies. Open resin 3D-printers in the range of 385 – 420 nm using DLP, MSLA, SLA or LCD technology can work with Liqcreate ESD. Plenty of different printers have been optimized prior to the release and many will follow in the coming weeks.

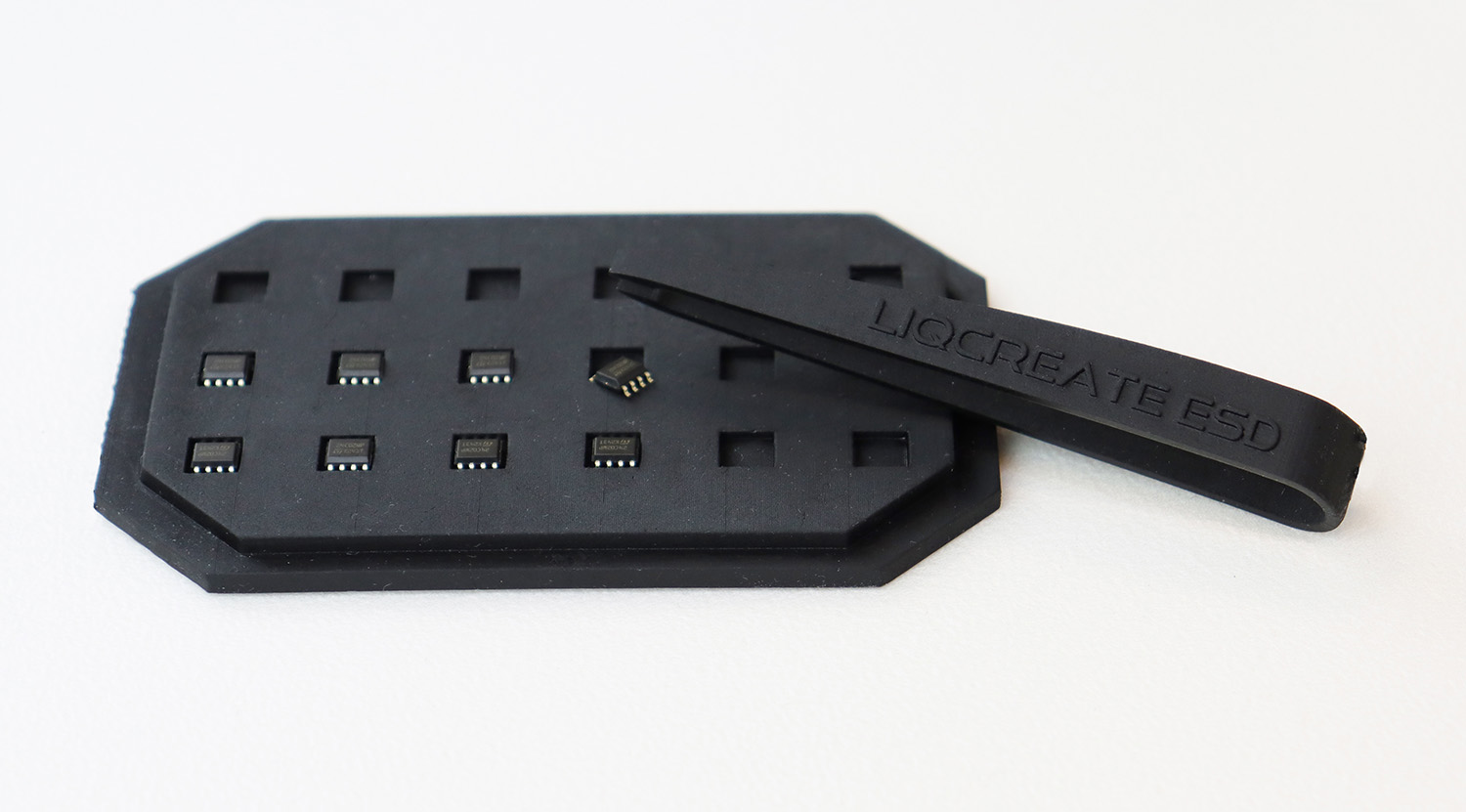

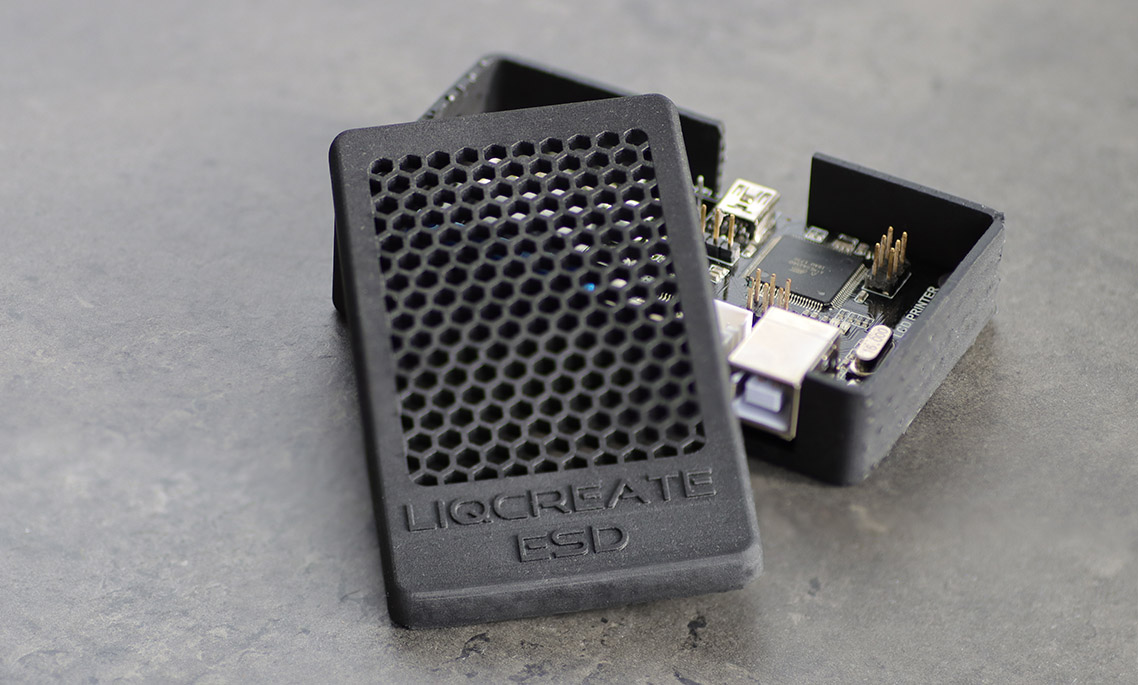

ESD 3D-printing applications for the electronics industry.

Liqcreate ESD resin is perfect for electronics manufacturers and companies in need of parts and tools for ESD-safe workplaces (EPA). Due to its isotropic electrostatic dissipative properties, it is suitable for electronic devices and components that require ESD. Reduce risk and increase manufacturing capabilities by printing custom jigs, fixtures and tools to protect critical electronics components from static discharge.

OEM possibilities for ESD resins & masterbatches

Next to theLiqcreate branded resin range, we also offer custom resin development for those in need of a non-standard formula for a specific application. Through this OEM service, customers can request the development of a 3D-printing resin with precise characteristics, which impact its print speed and color, as well as the properties of resulting parts.

When it comes to ESD resins, clients can request the formulation of materials with different properties. Think about elastomer or flexible ESD materials with a Shore A ranging from 45 to 95. Or high temperature ESD materials that can endure chip manufacturing cycles at elevated temperature. Once customers have started a custom material development project, Liqcreate’s engineers work to develop a resin according to their specifications, and provide guidance on how to dial in their new resins for a given printer, preparing them for production.

As an independent resin manufacturer with R&D facilities, Liqcreate is also able to rapidly scale its production of custom-made resins where needed. What’s more, the company’s standalone nature means there is little to no competition or conflict when working with 3D printer hardware manufacturers. As such, the firm is able to work quickly and get resins to market in quantity, without encountering issues that might otherwise keep clients waiting.

About Liqcreate ESD 3D resin

Liqcreate ESD is an opaque black photopolymer resin and can be processed on most resin based 3D-printers. 3D-printed parts from this material exhibit electrostatic discharge properties needed for electronic manufacturing and parts for ESD-safe workplaces (EPA). Liqcreate ESD can be used on open DLP, LCD and SLA 3D-printers in the range of 385 – 420nm.

Due to the isotropic electrostatic dissipative properties, it is suitable for electronic devices and components that require ESD. Reduce risk and increase manufacturing capabilities by printing custom jigs, fixtures and tools to protect critical electronics components from static discharge.

Key benefits |

3D-Printer compatibility |

| · Isotropic ESD properties | · Asiga series |

| · Well balanced rigidity and impact | · Shining3D Accufab-L4K |

| · Antistatic properties | · Elegoo & Anycubic series |

| · Easy to print | · And many more |