Modlock develops smart door opening system with Strong-X resin parts

Mechatronics students from HTL Rennweg used 3D-printing with Liqcreate Strong-X resin to develop a smart door lock system. Not only theoretical knowledge is required, the students also have to prove their technical know-how in a practical project. The special thing about this is that the team around Daniel Pfister is not only working intensively on a prototype, but has also secured a strong partners for the production of six finished devices. For their project, the HTL students have set their sights on an exciting product for smart homes: an electronic door opening system that can open door locks via app or keep them locked. “Our system is intended to replace mechanical locking systems in single- and multi-family homes in the future and makes key management much easier,” Pfister is convinced.

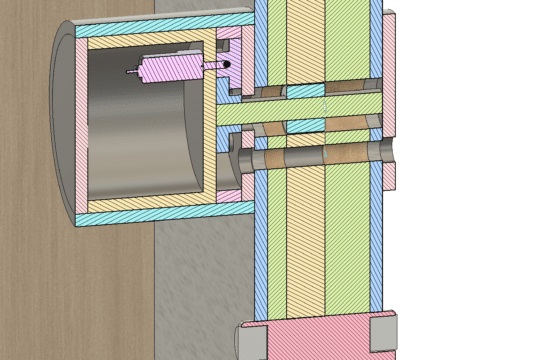

“For example, costs due to lost keys are eliminated and management for different people with different rights is simplified,” Pfister continues. With the system, access from the street to one’s own four walls takes place without a mechanical key, securely via a code, via NFC or via an app. The HTL students’ smart door opening system can be retrofitted easily and non-destructively to any conventional door. This simply involves replacing the handle with a rotary knob that contains the door opening system. “Security is very important here, so we control our module encrypted via Bluetooth,” explains Pfister. “It operates the door lock with a mechanical device to open the door. The system also works in the event of a power failure. So the door can be opened manually from the inside and by code from the outside,” Pfister says.

Within the scope of the project ”ModLock“, a modular door opening system with central administration is developed, manufactured and demonstrated. Modular means that there is a base station to which the individual opening modules and authentication modules are connected. The authentication modules have various types of control panels. The extended management functionality provided by the system’s base station proves to be a practical solution for larger, uniformly organised buildings, such as hotels, for securing all areas with appropriate methods.

Accordingly, there are three functional components that have been developed from scratch. These are the base station, the opening module and various authentication modules that communicate with each other wirelessly. Various interaction possibilities – made possible by a selection of sensors – with the authentication modules offer the user significantly more flexibility compared to commercially available products.

The system is designed in such a manner that the base station is positioned anywhere, whereas the opening module is mounted directly on the door and the associated authentication module is mounted in close proximity to it. The system is designed in such a way that a high degree of modularity and centralised management system are realised. Furthermore, available, and applicable guidelines as well as standards have been taken into account. These include, standards for mortise locks, as well as insurancerelated boundary conditions. The mortise locks, which are typically installed in interior doors, comply with ¨ONORM B 5350 and the opening direction of doors is specified according to ¨ONORM B 5328. Keeping the legal aspect in mind, the ModLock-system interacts with the latch of the mortise lock and not with the deadbolt, which additionally preserves the full function of the lock. Ergo, the term ”lock“ does not apply to the system, as it is an electronic door handle with extended functions.

Regarding the electronics, all requirements are fulfilled to ensure a self-sufficient operation of the modules for longer periods of time. In addition, the boards have wireless communication technology to make installation as simple as possible. Both the software and firmware allow for innovative centralised management and integration of all compatible sensors, with a platform-independent graphical user interface for easy and modern operation. The hardware of the modules was created using modern CAD software and a variation of manufacturing technologies, including additive methods such as 3d printing as well as subtractive methods such as metal cutting. The materials were selected after detailed research and the design was created whilst considering the peculiarities of the manufacturing processes.

3D-printing of the parts in Strong-X

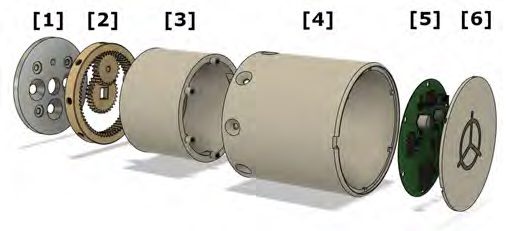

Liqcreate Strong-X was used for two different components in the ModLock-System. It was used to print the housing of the base station and some mechanical parts of the opening module. This allowed us to test Liqcreate Strong-Xt on both larger components with a larger tolerance and smaller components that need to be precise. The mechanical parts printed from Strong-X resin were the gears, which are marked in the image on the right. These gears are used to transmit torque from either the motor or the users hand to the internal locking assembly of the door.

“At the right side you can now find the gears printed with Liqcreate Strong-X resin. At this point we can say in advance that we were more than satisfied with the overall quality of the parts.” Pfister says.

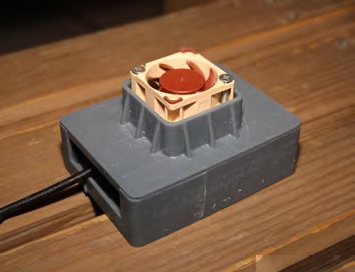

“After printing the gears for the transmission, we had some resin left and decided to use it for another part of the ModLock system. It was the base station housing which holds a Raspberry Pi and small fan. This housing was much more complicated to print due to its more complex structures. After curing, it also showed a very nice quality.” Pfister says.

“After printing the gears for the transmission, we had some resin left and decided to use it for another part of the ModLock system. It was the base station housing which holds a Raspberry Pi and small fan. This housing was much more complicated to print due to its more complex structures. After curing, it also showed a very nice quality.” Pfister says.

About Strong-X

Liqcreate Strong-X is one of the strongest materials available in the market. Its flexural strength of 135MPa is comparable to industry’s leading dual-cure cyanate ester resins. Liqcreate Strong-X is easy to use on all open source SLA and DLP 3D-printers in the range of 385 – 405nm and only requires UV post-curing. This material has excellent features like high strength, high stiffness and high temperature resistance which makes it ideal for injection molding and heavy duty applications.

Key benefits |

3D-Printer compatibility |

| · High strength | · Epax3D Series |

| · High temperature resistance | · Formlabs Form2 |

| · Low odor | · Asiga & Anycubic series |

| · Low shrinkage | · And many more |