When you are looking to invest in a plastic 3D printer for your business or use at home, there are a few 3D-printing technologies that are available. For small businesses or home users, entry level filament / FDM printers are an option but also resin 3D-printers. For medium and big businesses, there is a wide range of industrial options to produce plastic parts with jetting, SLS, resin 3D-printing (like DLP, SLA and MSLA) and filament / FDM 3D-printing. Crealityexpert.com made a great comparison between entry level resin and filament 3D-printers.

Resin vs filament FDM 3D-printing

To choose which printer technology is best for you, it is important to know what kind of parts and processing you want to do yourself. Each technology is a different tool meant for a different job. There are tradeoffs of both filament and resin 3D printers. Within this article you can learn the tradeoffs and learn more about the entry level 3D-printing options that fit best for your application.

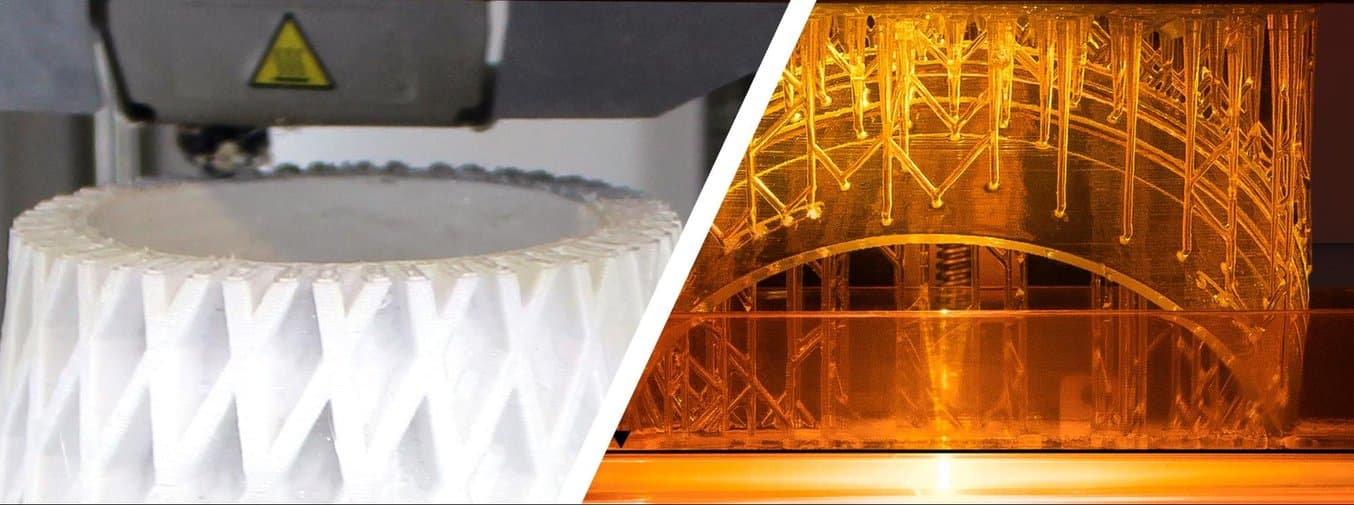

Image by Formlabs: Filament FDM 3D-printer on the left and SLA resin 3D-printer on the right.

The basics of FDM filament and resin 3D-printing

The filaments used in 3D printing are thermoplastics, which are plastics that melt rather when heated. Thermoplastics can be shaped and molded when hot, and solidify when cooled. The filament is fed into a heating chamber in the printer’s extruder assembly, where it is heated to its melting point and then extruded through a metal nozzle. When the extruder assembly moves, tracing a path programmed into a 3D object file to create, layer by layer, the printed object.

Resin printers form parts from liquid resin which cures and gets solid, when it is exposed to UV light. Similar to Filament printers, resin printers build parts in layers. The difference is that it will get solidified when a part is exposed by light. Each slice to a pattern of UV light will solidify the resin in the desired locations. There are three types of common resin 3D-printers, DLP (digital light processing), SLA (Stereolithography) and MSLA (Microstereolithography. These technologies differ in how they cure the resin. A DLP 3D-printers use a DMD chip and projector (basically like the old dia projectors) to cure an entire layer at once.

SLA printers use a laser which traces a path through the resin. On the spot where the laser hits the resin, the resin will cure and solidify. From the outside, these printers are very similar. Since the rise of the LCD based printing (MSLA), the prices of resin based 3D-printing systems has gone down to the level of FDM printers. That is why most lower cost resin printers use almost the same LCD / MSLA technology.

When considering which of these types of 3D printers to purchase, you’ll first need to think about what kind of parts you are planning to make. Filament printers work well for producing parts with thermoplastic properties and are often larger parts. Resin printers excel at producing fine details and can print much more precisely on small parts, but uses thermosetting resin. There are a few more important factors to consider when choosing which of these technologies is best for your specific needs.

Print Quality of resin vs filament 3D-printers

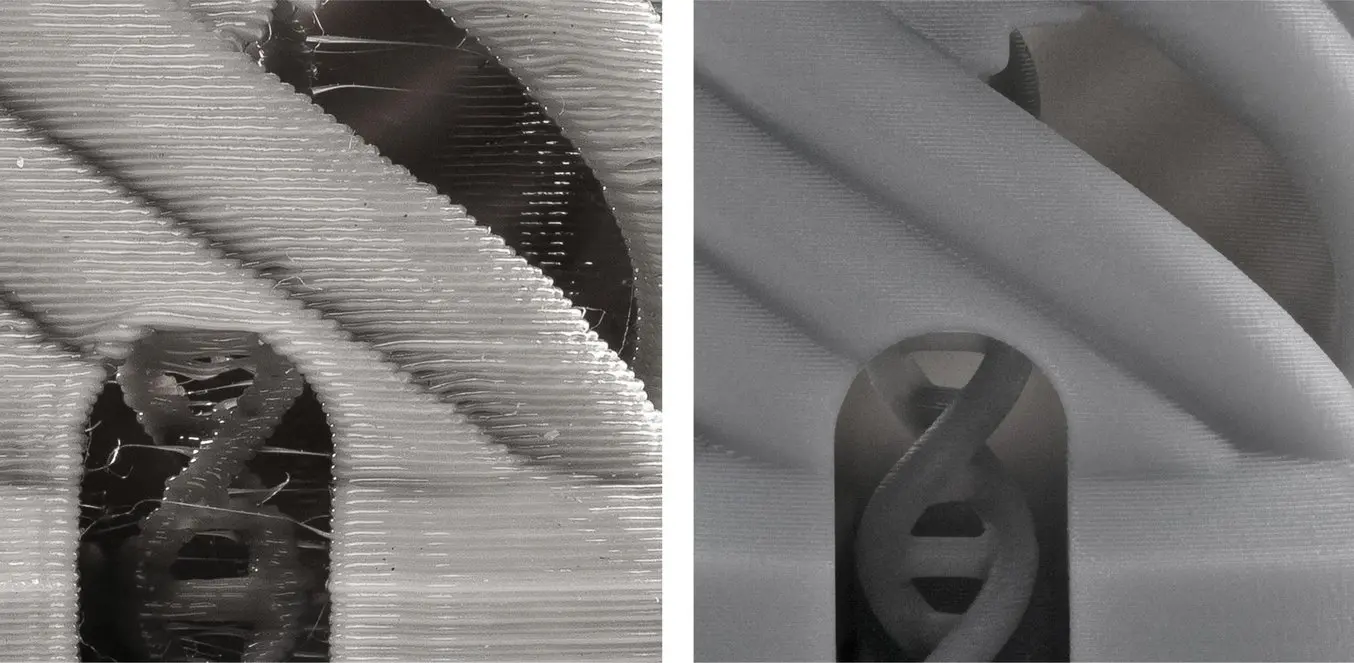

Resin printers are known for their superior surface quality, both in small details on prints and for producing models with almost no visible layer lines. For comparison, each layer on a resin printer is typically 25 – 100 microns thick, while filament printer layers are typically 100 – 300 microns thick. Even when printing at 100 micron layer thickness on both technologies, resin 3D-printed parts are much more detailed and accurate.

Resin printers are able to capture very fine details because the resolution of each layer is defined by the size of pixels on the LCD screen, which are typically in the range of 50 microns for consumer MSLA 3D printers. For some specialized printers like the Phrozen Sonic Mini 8K, the pixel size is even smaller at 22 micron. For filament printer the resolution is limited by the size of the opening in the nozzle where melted material is deposited, which is typically 0.4 mm (400 microns). It is possible to install smaller nozzles on filament printers, but the smallest viable nozzles are still 200 microns. Such a nozzle will also increase the printing time for the filament printer significantly according to CrealityExperts.

Image by Formlabs: Filament FDM 3D-printer on the left and SLA resin 3D-printer on the right.

If you are looking to make detailed objects such as mini-figures, jewelry parts, dental applications, or parts where high accuracy is critical, resin printers are a great choice.

Printing Speed of resin vs FDM filament 3D-printing

With typical settings, filament printers can produce single objects quite fast faster. If you add more objects to the print bed, the print time will increase proportionally. This is because the nozzle must trace each part individually. Resin printers like MSLA and DLP printers can print multiple parts with the same print time as a single object. The LCD and DLP expose each layer for a fixed amount of time regardless of how many parts you are printing. In these cases, resin can often be substantially faster for cases where you need a lot of parts.

Printed part durability resin vs FDM filament

Parts printed from filament use thermoplastic materials with their known thermoplastic properties. Next to the general used PLA, you can use alternate materials such as PETG and ABS which offer increased strength and heat/UV resistance for parts used outdoors. Parts printed by an FDM 3D printer do have substantially less strength when forces are acting across layers. Meaning that the strength in Z-axis is usually much weaker compared to the strength in XY direction. Therefor it is critical to consider the orientation of parts to maximize strength.

Standard resin prints are fairly brittle and are typically not preferred for functional parts that will be exposed to substantial force or aging. Additionally, for standard resins, exposure to sunlight causes the prints to become weaker over time. For outdoor applications it is important to select the right resins that can withstand UV aging. Additionally, it is important to read the technical data sheet of each material to understand its properties.

Build Volume & print speed in resin vs FDM filament 3D-printing.

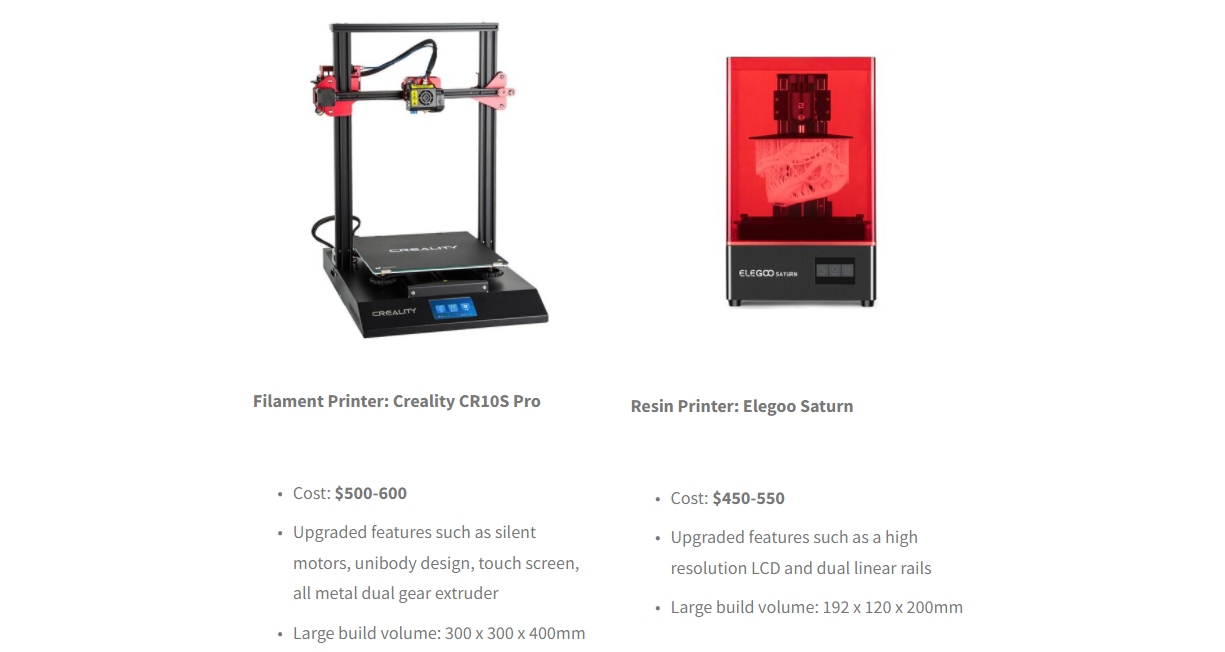

When you are looking to print large parts, filament printers have an advantage. Entry-level FDM 3D-printers as the Creality Ender 3 have a build volume of 220 x 220 x 250 mm. One model larger, the Creality XR-10 Max has even a print volume of 450 x 450 x 475 mm. For filament FDM printers a larger build volume is easier to develop, and larger printers are easier to find.

The entry-level resin 3D-Printers have a smaller build volume. Entry level printers such as the Elegoo Mars 2 can print up to 129 x 80 x 160 mm. Large format Resin printers such as the Elegoo Saturn are 192 x 120 x 150 mm, and are still substantially smaller than even the entry level filament printers. Even larger models are available as well like the Phrozen Sonic Mega 8K, Elegoo Jupiter, Anycubic Photon M3 Max and the Peopoly Phenom Prime.

The build volumes of these printers are:

Anycubic Photon M3 Max 300 * 164 * 298 mm

Elegoo Jupiter 278 * 156 * 300 mm

Phrozen Sonic Mega 8K 330 * 185 * 400 mm

Peopoly Phenom Prime 276 × 155 x 400 mm

Ease of use and post-processing resin vs filament

Resin 3D printers are simple to set-up, the photopolymer resin can add some complications. It is important to note that liquid resin is a chemical. It is important to read the safety data sheet before using a new resin. The SDS will also tell the PPE’s to use, like to wear gloves whenever there is a chance to come in contact with the resin. Additionally, some resins can have a distinct odor and it is recommended to keep resin 3D printers in a well-ventilated area. The resin odor varies from resin to resin. Most cheap resins are formulated from cheap building blocks that can be quite smelly. Most Liqcreate resins have no / low odor. Send an e-mail to info@liqcreate.com to learn more about this.

Resin 3D-printing always requires post-processing, while this is optional for FDM filament printing. Completed prints have remaining liquid photopolymer resin on the surface once they are finished. You will need to wash and post-cure the resin printed parts. Washing solvents can be Isopropyl Alcohol (IPA), Ethanol or Liqcreate resin cleaner. The solvent will become saturated with resin and become ineffective after using it a few time. When the effectivity drops, it is advised to renew the washing solvent and dispose it following local regulations.

Filament printers are easier to use once they are set-up. All of the materials can be handled safely with no protection, and no post processing is required for most prints. After printing, the support structures have to be removed and additional post-processing is optional. For instance with you can smooth ABS 3D-printed parts by spraying acetone on the surface. Read the instructions before trying this because it also reduces accuracy!

Image by All3DP.com: Smoothing the surface of ABS filament 3D-printed parts.

Cost in resin vs FDM filament 3D-printing.

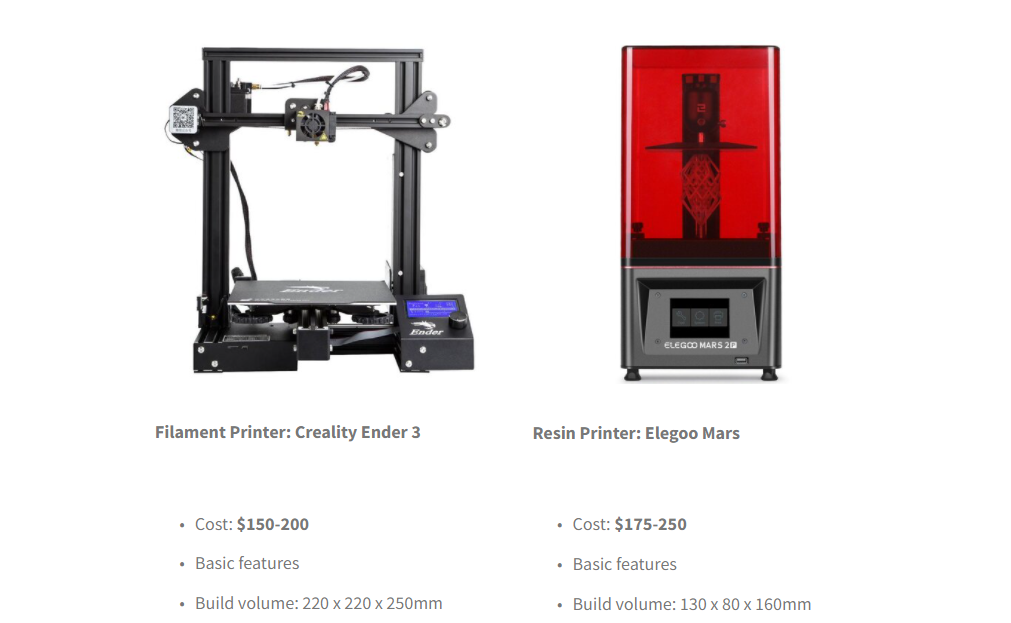

Years ago purchasing a resin 3D printer was much more expensive compared to a filament 3D-printer. With the introduction of the low-cost LCD-based MSLA resin 3D-printers, this has changed. Due to this technology, entry-level budget resin 3D printers are priced in the same range as entry level filament 3D printers. You have plenty of options when you are looking for a budget resin 3D printer or a budget filament 3D printer. CrealityExperts has made a comparison between entry-level resin and FDM filament 3D-printers. See their side by side comparisons.

Entry Level resin and filament 3D-printers

Image by CrealityExperts: the entry-level resin and filament 3D-printers, the Creality Ender 3 on the left and Elegoo Mars on the right.

Mid-range / size resin and filament 3D-printers

Image by CrealityExperts: the entry-level resin and filament 3D-printers, the Creality CR10S Pro on the left and Elegoo Saturn on the right.

Large size resin and filament 3D-printers

Image by CrealityExperts: the entry-level resin and filament 3D-printers, the Ultimaker S3 on the left and Peopoly Phenom Prime on the right.

Industrial resin and filament 3D-printers

Stratasys recently launched its industrial FDM 3D-printer the F123. TheF123 Series printers combine industrial-grade capability with simple operation. Requiring no special expertise, F123 printers offer carbon fiber 3D printing, fast and easy material swaps and auto-calibration for accurate, dependable results. It has a build volume up to 355 x 254 x 355 mm and more than 8 industrial filaments available. The smallest machine (with smaller build volume and 2 materials available) has a starting price of $20.000 according to TCT magazine.

Image by 3Dprintingindustry.com: The new Stratasys F123 series of FDM filament 3D-printers.

Industrial resin 3D-printers are also available, for instance the Nexa3D NXE400. With a build volume of 275 x 160 x 400 mm, intelligent optimization, and Nexa3D’s revolutionary patented Lubricant Sublayer Photocuring (LSPc) technology, the NXE 400 photopolymer 3D printer is perfect for any application.

Ongoing Costs in resin and FDM 3D-printing

According to CrealityExperts: Its important to consider the total down of ownership of a 3D printer, because the ongoing costs can be a more substantial portion of the total cost than the purchase price of the machine itself. The majority of ongoing costs are the materials you use to make parts: the filament or resin.

Overall, the cost of resin is higher per kilogram, but you will likely use less with a resin printer due to its smaller build size. If you are planning to print larger parts on your resin printer, you can reduce resin usage by making the parts hollow and including a drain hole to allow the unused resin in the center cavity to drain out. Additionally you have to count the costs of the washing solvents and it is highly recommended to purchase a washing unit and curing unit to get the best results. For filament printers, parts typically use a meshed infill pattern, which saves material.

Additional costs for resin 3D-printing are the FEP film on the bottom of your resin tank and occasionally a new LCD screen when your printer uses MSLA technology. For filament 3D-printing, the extruder which pushes filament, and the hot end which melts it before depositing it onto the part are generally the first parts that need replacement. FDM filament printers require a slightly more maintenance, but the differences are small.

With all this information, we hope you can have enough technical know-how to decide which printing technology is best for you. If you have any questions or comments, feel free to send an e-mail to info@liqcreate.com.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!