Technical specifications

Liqcreate Composite-X has a flexural modulus over 9000 MPa and a flexural strength of 150 – 170 MPa. The material can be used after UV-post curing, or the properties can be boosted with a thermal cure. Composite-X features an excellent chemical resistance, high strength and high stiffness, perfect for rapid tooling, wind tunnel testing and industrial applications.

| Mechanical Properties | Metric[1] | ||

|---|---|---|---|

| Description | Method | UV curing 60 min. at 60°C | UV curing 60 min. at 60°C & thermal curing 120 min. at 100°C |

| Tensile strength | D638 | 50 – 75 MPa | 70 – 85 MPa |

| Tensile modulus | D638 | 7.5 – 8.5 GPa | 8.5 – 9.5 GPa |

| Elongation at break | D638 | 1% | 1% |

| Flexural strength | D790 | 140 – 150 MPa | 150 – 170 MPa |

| Flexural modulus | D790 | 7.5 – 8.5 GPa | 8.5 – 9.5 GPa |

| IZOD Impact (notched) | D256A | 19 J/m | 18 J/m |

| Shore D Hardness | D2240 | 93 | 94 |

| Water sorption | D570-98 | 0.67% | 0.59% |

| Linear Shrinkage during printing | Internal method | <0.1% | <0.1% |

| Linear Shrinkage during UV-curing | Internal method | 0.5% | 0.5% |

| Linear Shrinkage during thermal cure | Internal method | 0.1% | 0.1% |

| Compression strength | D695 | 155 MPa | 160 MPa |

| Density solid | Internal method | 1.62 g/cm3 | 1.62 g/cm3 |

| HDT-B 0.45 MPa | ISO75 | 77°C | 86°C |

| Degradation temperature | Internal method | >200°C[2] | >200°C[2] |

[1]Post-cured in the Wicked Engineering Curebox. These values may vary and depend on individual machine processing and post-curing. [2]Discoloration at 200°C, no cracking in part up to 200°C / 392°F.

| Description | Value |

|---|---|

| Appearance | Opaque white liquid |

| Viscosity | 1400 cps at 25°C |

| Density | 1.52 g/cm3 |

| Ec | 9.55 mJ/cm2 |

| Dp metric | 0.18 mm |

| Dp imperial | 7.09 mils |

More information

Values may vary and depend on individual machine processing and post-curing. For extra details, download the technical data sheet or user guide.

Processing instructions

New to resin 3D-printing, or a seasoned professional, it is advised to scroll through the processing instructions. Detailed informatin on printing parameters, support settings, cleaning, washing, post-curing, part orientation, shrinkage compensation, minimum wall thickness and other resin behaviour can be found in the link.

| H315: Causes skin irritation. |

| H317: May cause an allergic skin reaction. |

| H319: Causes serious eye irritation. |

3D Printer compatibility

Do you want to use Composite-X? Check if settings are available on our website for your printer!

| Printer name | Compatible? |

| atum3D DLP Station 5 | Yes |

| UnionTech Martrix300 | Yes |

| Shining3D AccuFab-L4K | Yes |

| Ackuretta Freeshape 120 | Yes |

| Prusa SL1 | Yes |

| Prusa SL1S Speed | Yes |

| 3DWare Zeta 4K | Yes |

| Anycubic Photon | Yes |

| Anycubic Photon Mono | Yes |

| Anycubic Photon Mono 4K | Yes |

| Anycubic Photon Mono SE | Yes |

| Anycubic Photon Mono X | Yes |

| Anycubic Photon Mono X 6K | Yes |

| Anycubic Photon M3 | Yes |

| Anycubic Photon M3 Plus | Yes |

| Anycubic Photon M3 Max | Yes |

| Anycubic Photon Mono M7 Pro | Yes |

| Anycubic Photon D2 | Yes |

| Elegoo Mars | Yes |

| Elegoo Mars 2 | Yes |

| Elegoo Mars 3 | Yes |

| Elegoo Mars 4 | Yes |

| Elegoo Mars 4 Ultra | Yes |

| Elegoo Mars 5 | Yes |

| Elegoo Saturn | Yes |

| Elegoo Saturn 2 | Yes |

| Elegoo Saturn 3 | Yes |

| Uniformation GKTwo | Yes |

| Phrozen Sonic Mini 4K | Yes |

| Phrozen Sonic Mighty 4K | Yes |

| Phrozen Sonic Mighty Revo 14K | Yes |

| Phrozen Sonic Mini 8K | Yes |

| Phrozen Sonic Mini 8K S | Yes |

| Peopoly Phenom L | Yes |

| Zortrax Inkspire | Yes |

| Zortrax Inkspire 2 | Yes |

| Peopoly Phenom Prime | Yes |

| Creality LD-002H | Yes |

| Creality Halot-Sky | Yes |

| Creality Halot-Mage Pro 8K | Yes |

| PicoFAB 4K | Yes |

| Nexa3D XiP | Yes (open license) |

| Intrepid Automation Epic production system | Yes |

| Intrepid Automation Epic development kit | Yes |

| Asiga Freeform PICO | Yes |

| Asiga Max UV & Pro 4K | Not compatible |

| 385 – 420nm MSLA, SLA & DLP printer | Contact us |

Composite-X use cases

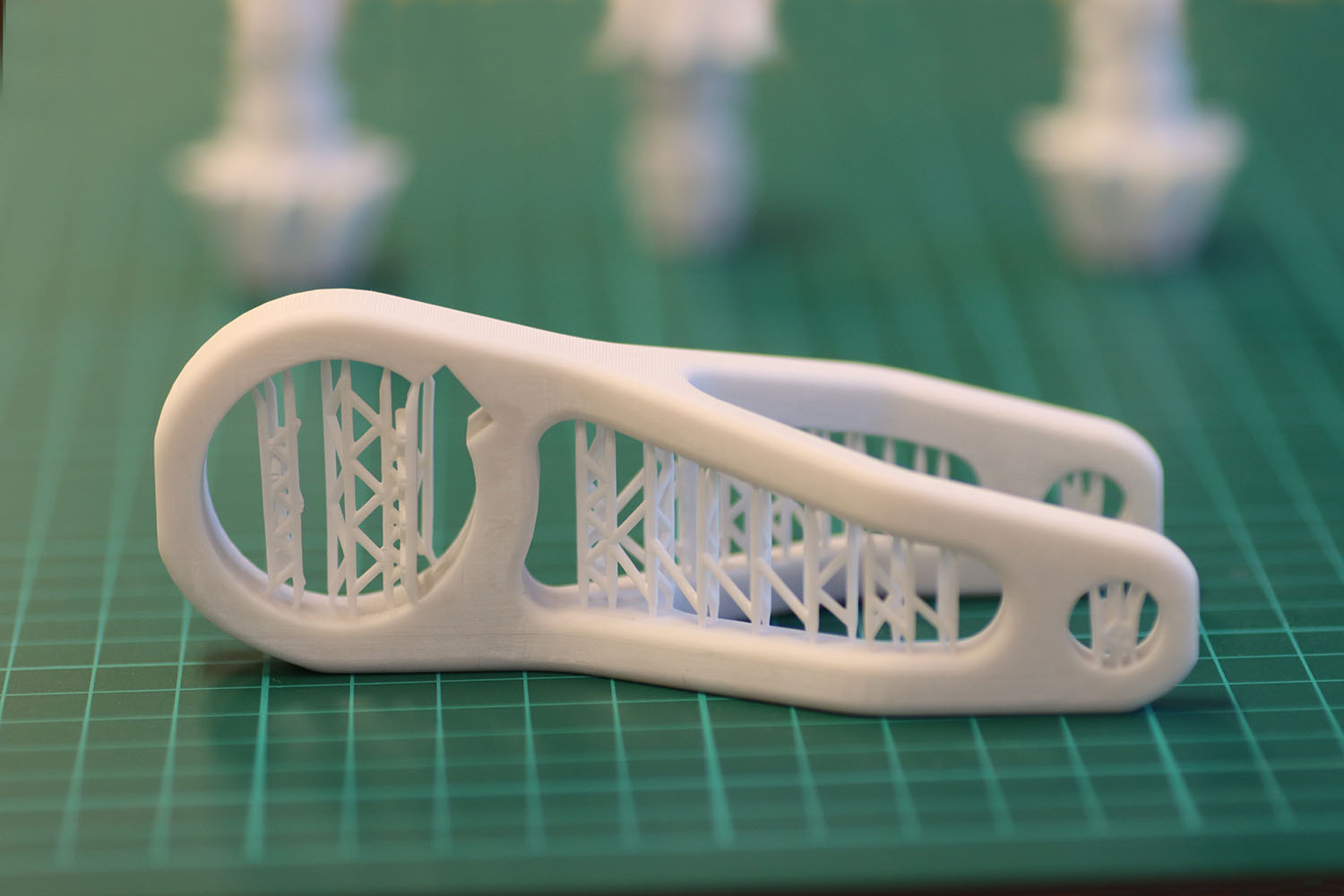

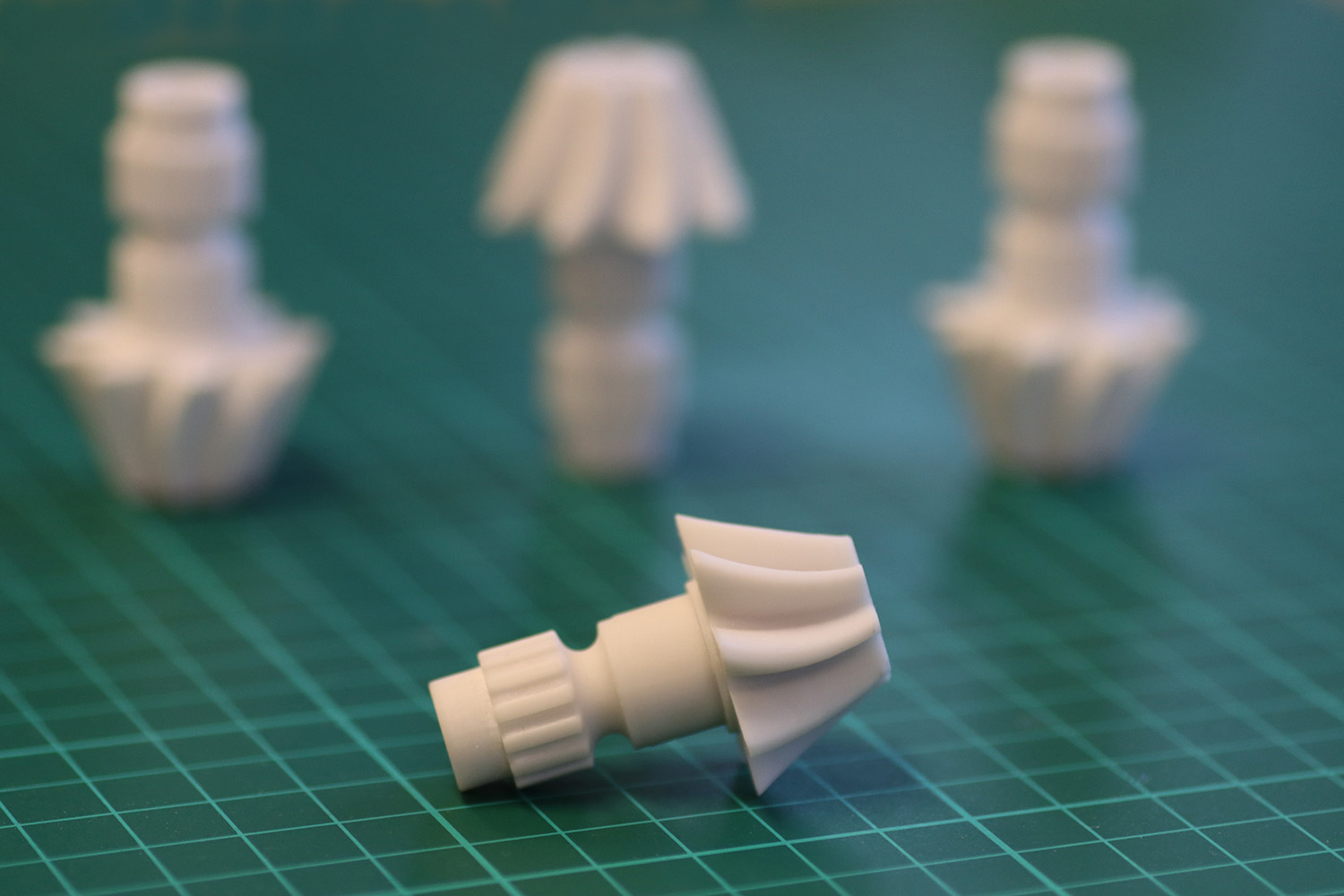

Liqcreate Composite-X has features like excellent chemical resistance, high strength and high stiffness which makes it ideal for wind tunnel testing, fluid flow components, automotive and heavy duty industrial applications.

Reviews

There are no reviews yet.