In the past years we have heard and read about the idea of increasing the toughness of a resin by UV post-curing the parts very shortly. With our extended experience with resin 3D-printing and its properties, we do not advise to pursue this strategy for high demanding applications. Why? Read all about it in this article.

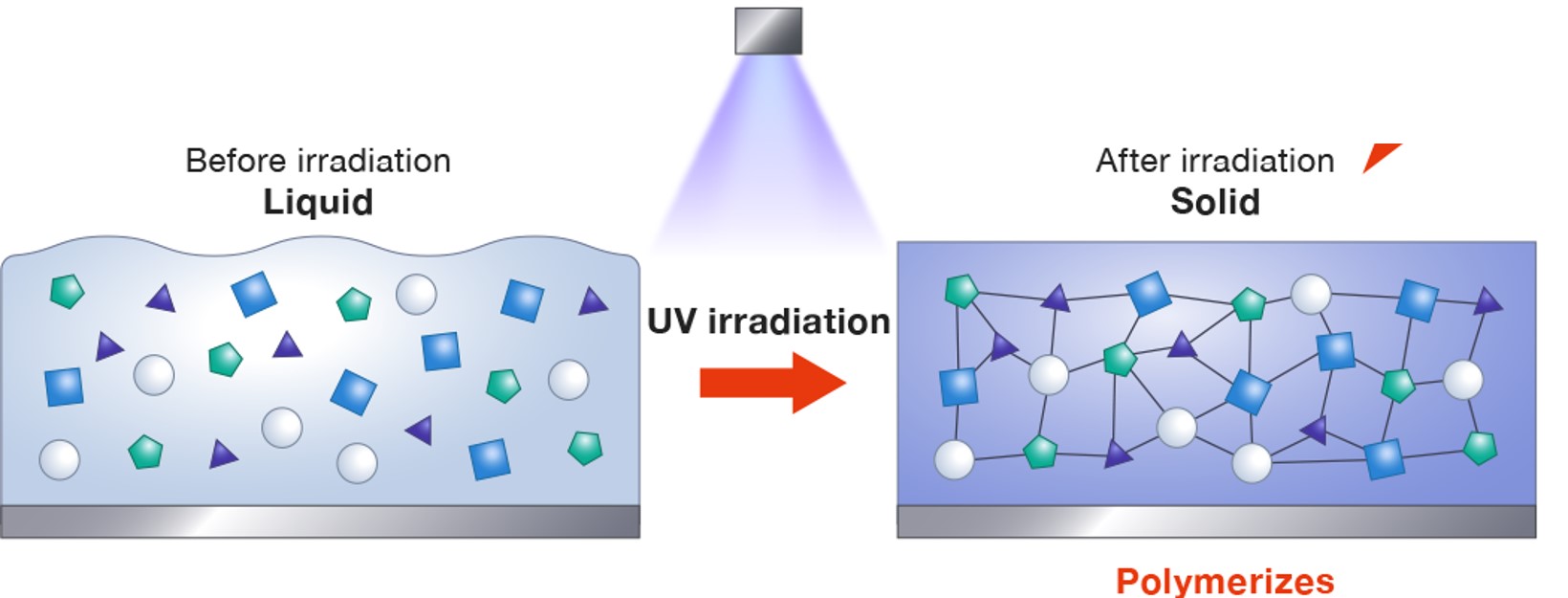

image by threebond group: schematic representation what happens during UV-post-curing.

What does post-curing to your 3D-printed part and toughness?

Liquid resins are build-up from acrylates or methacrylates. With a photoinitiator and additives added to this system, they can respond and polymerize to the right wavelength of light. The properties of a resin are coming from the backbone of the material, the chemical interaction of the molecules and the cross-link density. The last one has an huge effect on if a part feels brittle or not. What happens is that if you cure a resin longer, it will react more and will become more rigid i.e. creating more cross-links. By UV post-curing less you are actually creating less cross-links. This will (temporarily) give a tougher and more flexible polymer.

Why is this not a long-term solution?

We are always striving to get close to 100% polymerization in each polymer part by post-curing it long enough and often at elevated temperatures (during UV-curing in one step post-processing). This way your part does not change much anymore over time. Of course there is UV-aging or thermal aging when placing it in a more demanding environment. If you don’t cure your part 100%, trying to make it tougher with less post-curing. These parts will cure on its own on your desk, getting rigid and more brittle faster over-time. So it is advised to choose a more advanced resin which is actually tough when it is cured to almost 100%. Our tough polymers, Premium Tough, Tough-X and Clear Impact might be interesting for your application.

What about brittleness during thermal and UV-aging?

It is known that 3D-printing resins do age when exposed to thermal or UV sources for extended times. This process is different compared to the situation of low post-curing times explained below. If you have a 100% cured network, UV rays can damage the polymer chain and increase the cross-link density even higher even though the network is formed 100%. For 100% cured materials, the effect is much lower. Learn more in the links below to see which material fits your requirements.

– Chemical resistant / chemical compatibility study

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!