Technical specifications

A biocompatible 3D-printing resin for Digital Light Processing (DLP), Liquid Crystal Display (LCD) and laser based 3D-printers. Liqcreate Bio-Med Clear is perfect for applications that require non-cytotoxic, non-sensitizing and non-irritating features.

| Mechanical Properties | UV post-curing | ||

|---|---|---|---|

| Description | Method | Metric[2] | Imperial[2] |

| Tensile strength | D638 | 55 MPa | 8.00 ksi |

| Elongation at break | D638 | 5 – 10% | 5 – 10% |

| Tensile modulus | D638 | 2.0 GPa | 290 ksi |

| Flexural strength | D790 | 89 MPa | 12.91 ksi |

| Flexural modulus | D790 | 2.2 GPa | 319 ksi |

| Flexural strength | ISO 20795-2 | 78 MPa | 11.31 ksi |

| Flexural modulus | ISO 20795-2 | 1.7 GPa | 274 ksi |

| IZOD Impact notched | ISO 180 | 3.04 kJ/m2 | 1.45 ft-lb/in2 |

| IZOD Impact notched | D256 | 28 J/m | 0.53 ft-lb/in |

| Water sorption | D570-98 | 0.54% | 0.54% |

| Degradation temperature | Internal method | >250°C[3] | >482°F[3] |

| HDT-B 0.45 MPa | ISO75 | 62°C | 144°F |

| HDT-A 1.80 MPa | ISO75 | 48°C | 118°F |

| Shore D Hardness | D2240 | 85 | 85 |

| Cytotoxicity | ISO 10993-5 | pass | pass |

| Sensitization | ISO 10993-10 | pass | pass |

| Irritation | ISO 10993-23 | pass | pass |

[1]Follow the processing instructions to obtain biocompatible parts. [2]Washed in IPA for 2 x 3 minutes in an ultrasonic cleaner. The second wash cycle is performed in fresh IPA followed by 30 minutes resting and post-curing for 30 minutes with LED at 60°C in the Wicked Engineering Curebox. These values may vary and depend on individual machine processing and post-curing. [3]Softening above HDT, but no cracking in part up to 250°C / 482°F.

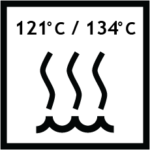

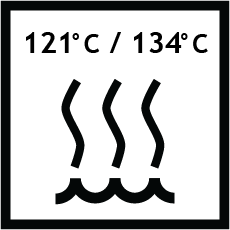

Steam sterilization & desinfection

Printed parts from Bio-Med Clear can be disinfected with commonly used disinfectants and sterilized by steam sterilization using an autoclave. Standard steam sterilization programs have been validated at 121°C / 250 °F and at 134°C / 273°F for this biocompatible resin.

| Description | Method | After UV-cure | After steam sterilization 121°C | After steam sterilization 134°C |

|---|---|---|---|---|

| Flexural strength | ISO 20795-2 | 78 MPa | 75 MPa | 73 MPa |

| Flexural modulus | ISO 20795-2 | 1.7 GPa | 2.2 GPa | 2.2 GPa |

| Flexural strength | ASTM 790 | 89 MPa | 80 MPa | 75 MPa |

| Flexural modulus | ASTM 790 | 2.2 GPa | 2.5 GPa | 2.4 GPa |

| Description | Value |

|---|---|

| Appearance | Clear liquid |

| Viscosity | 475 mPa⋅s at 25°C |

| Density | 1.18 g/cm3 |

| Ec (405nm) | 6.10 mJ/cm2 |

| Dp (405nm) | 0.12 mm |

| Ec (385nm) | 4.10 mJ/cm2 |

| Dp (385nm) | 0.05 mm |

More information

Values may vary and depend on individual machine processing and post-curing and therefor it is important to follow the instructions of Liqcreate Bio-Med Clear resin carefully to achieve biocompatible properties. For extra details, download the technical data sheet or user guide.

⤓ Technical Data Sheet ⤓ User Guide ⤓ Processing Instructions

Processing instructions to obtain biocompatible properties

New to resin 3D-printing, or a seasoned professional, it is advised to scroll through the processing instructions. Detailed information on how to obtain biocompatible resin end products, printing parameters, support settings, cleaning, washing, post-curing, part orientation, shrinkage compensation, minimum wall thickness and other resin behaviour can be found in the link.

| H317: May cause an allergic skin reaction. |

| H413: May cause long lasting harmful effects to aquatic life. |

3D Printer compatibility

Do you want to use Liqcreate Bio-Med Clear resin? Check if Bio-Med Clear printing settings are available on our website for your printer! Contact us if your printer is not listed.

| Printer name | Compatible? |

| NextDent LCD1 | Yes |

| Asiga Max UV | Yes |

| Asiga Max 2 | Yes |

| Asiga Pro 4K | Yes |

| Asiga Ultra | Yes |

| Martrix300 | Yes |

| Martrix520 | Yes |

| Evodent E128 | Yes |

| Prusa SL1S Speed | Yes |

| Prusa Medical One | Yes |

| Shining3D AccuFab-L4K | Yes |

| Raise3D DF2 | Yes |

| W2P SolFlex 150 | Yes |

| W2P SolFlex 163FHD | Yes |

| W2P SolFlex 170 | Yes |

| W2P SolFlex 250UHD | Yes |

| W2P SolFlex 350 | Yes |

| W2P SolFlex 363 | Yes |

| W2P SolFlex 650 | Yes |

| W2P SolLab 370 | Yes |

| atum3D DLP Station 5-405 | Yes |

| atum3D DLP station 5-405 EXZ | Yes |

| Anycubic Photon | Yes |

| Anycubic Photon S | Yes |

| Anycubic Photon Mono | Yes |

| Anycubic Photon Mono 2 | Yes |

| Anycubic Photon Mono 4 Ultra | Yes |

| Anycubic Photon Mono SE | Yes |

| Anycubic Photon Mono X | Yes |

| Anycubic Photon Mono X 6Ks | Yes |

| Anycubic Photon M3 | Yes |

| Anycubic Photon M3 Plus | Yes |

| Anycubic Photon M3 Max | Yes |

| Anycubic Photon Mono M5s | Yes |

| Anycubic Photon Mono M5s Pro | Yes |

| Anycubic Photon Mono M7 Pro | Yes |

| Anycubic Photon Ultra | Yes |

| Anycubic Photon D2 | Yes |

| Epax3D X1N | Yes |

| Flashforge Focus 6K | Yes |

| Flashforge Hunter S | Yes |

| Uniformation GKTwo | Yes |

| Elegoo Mars 2 | Yes |

| Elegoo Mars 3 | Yes |

| Elegoo Mars 4 | Yes |

| Elegoo Mars 4 Ultra | Yes |

| Elegoo Mars 5 | Yes |

| Elegoo Mars 5 Ultra | Yes |

| Elegoo Saturn | Yes |

| Elegoo Saturn 8K | Yes |

| Elegoo Saturn 3 | Yes |

| Elegoo Saturn 3 Ultra | Yes |

| Elegoo Saturn 4 Ultra | Yes |

| Peopoly Phenom Prime | Yes |

| Creality Halot-One | Yes |

| Creality Halot-Sky 6K 2022 | Yes |

| Creality Halot-Mage Pro 8K | Yes |

| Phrozen Sonic Mini | Yes |

| Phrozen Sonic Mini 4K | Yes |

| Phrozen Sonic Mini 8K S | Yes |

| Phrozen Sonic Mighty 4K | Yes |

| Phrozen Sonic Mighty 8K | Yes |

| Phrozen Sonic Mighty Revo 14K | Yes |

| Phrozen Sonic Mega 8K | Yes |

| Phrozen Sonic Mega 8K S | Yes |

| Phrozen Sonic XL 4K 2022 | Yes |

| Phrozen Sonic XL 4K Plus | Yes |

| Phrozen Lumii DLP | Yes |

| Nexa3D XiP | Yes (open license) |

| Formlabs | Not compatible |

| 385 – 420nm MSLA, SLA & DLP printer | Contact us |

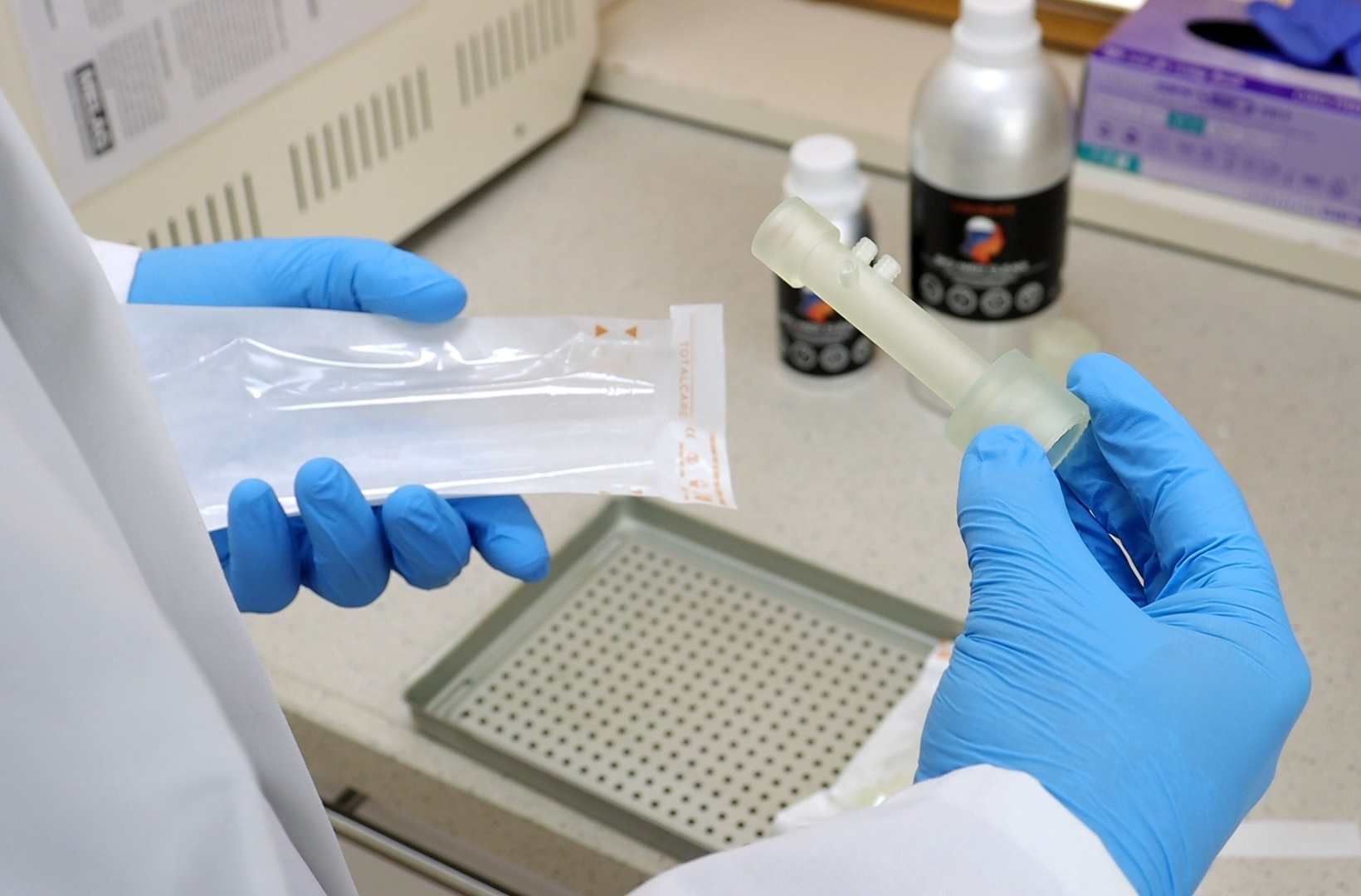

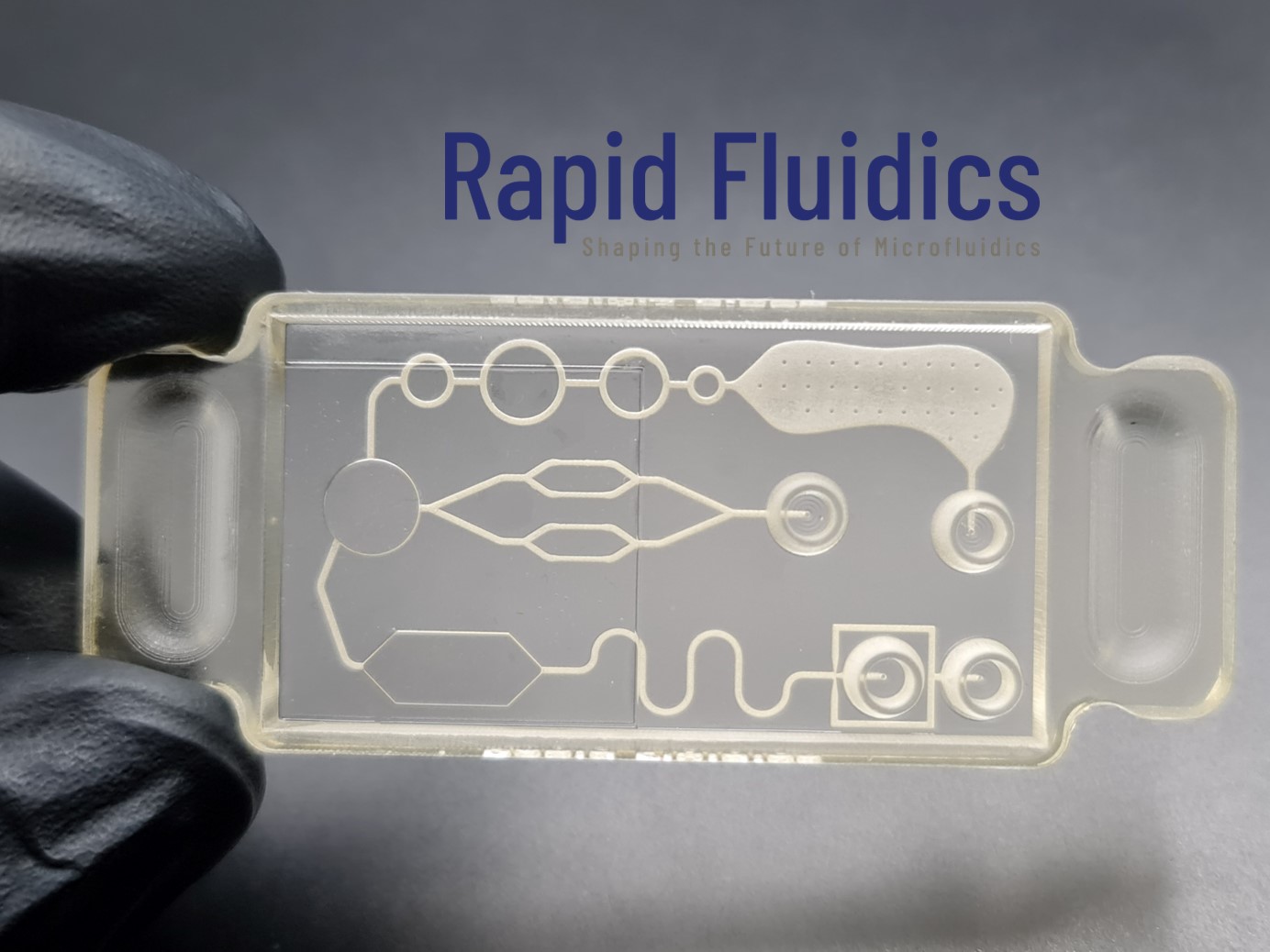

Bio-Med Clear use cases

Bio-Med Clear is a biocompatible 3D-printing resin for Digital Light Processing (DLP), Liquid Crystal Display (LCD / MSLA) and laser based resin 3D-printers. Liqcreate Bio-Med Clear is perfect for applications that require biocompatible features like non-cytotoxic, non-sensitizing and non-irritating.

Reviews

There are no reviews yet.