An important factor in the quality of 3D-printed parts is the support structures. These supports can vary for each 3D-printer and for each material.

Support of resin 3D-printed parts

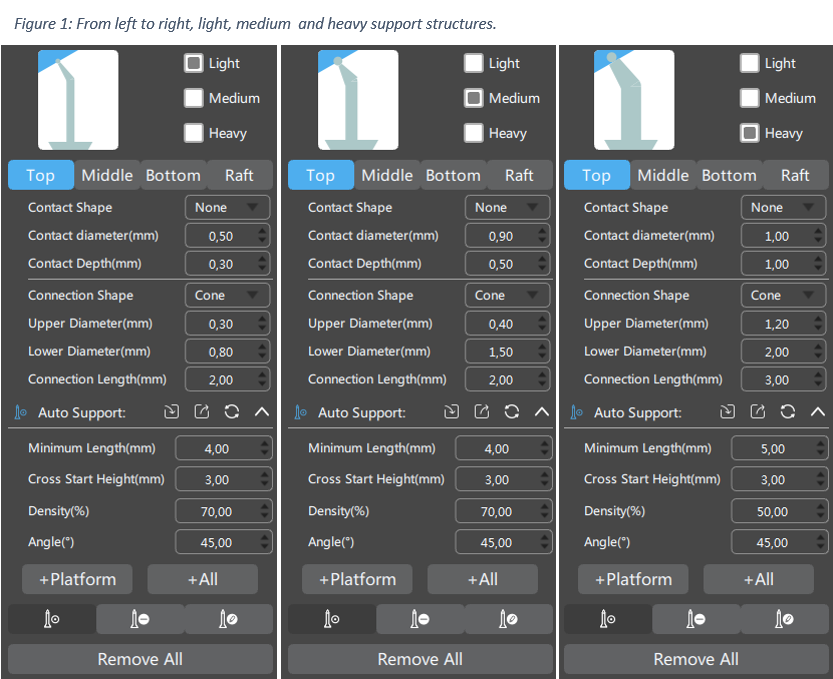

In general rigid polymers like Deep Blue, Strong-X, Premium White/Black/Model are easy to print with a combination of light and medium supports as shown in Figure 1. A different support strategy works best for printing tough and flexible resins. Especially for Tough-X, Flexible-X and Premium Flex, we advise to use heavy supports. Premium Tough is more rigid compared to Tough-X and can also be printed with medium support structures.

Just like all other parts, it is important to always support local low points and overhangs. Big overhangs are difficult to print due to the flexible nature of our Tough-X, Flexible-X and Premium Flexible resin during the 3D-printing process. These overhangs can be minimized by smart orientation of the file and placing support structures on the overhangs.

Support and raft structure for Wax Castable 3D-printing resin

Wax based 3D-printing resins can have reduced adhesion to painted or anodized build plates. For instance the build plates of the Elegoo Mars series need different settings to get succesful prints. These settings are explained in this support article, together with more tips and tricks when working with wax based resins. All that remains is to wish you good luck with 3D-printing. If there are any questions, comments or if you need help with anything, please contact Liqcreate: info@liqcreate.com.

Support

Do you need any help with 3D printing our SLA, DLP or LCD resins? We can help you! Just look for the question you have below. If you can’t find it, let us know by contacting us!